Ingcaciso yeMveliso

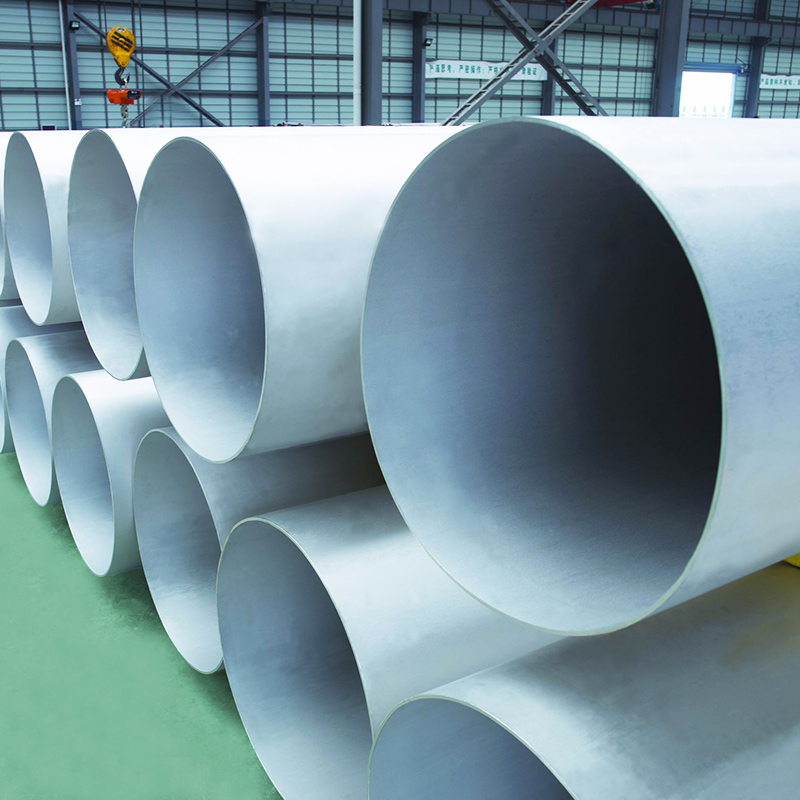

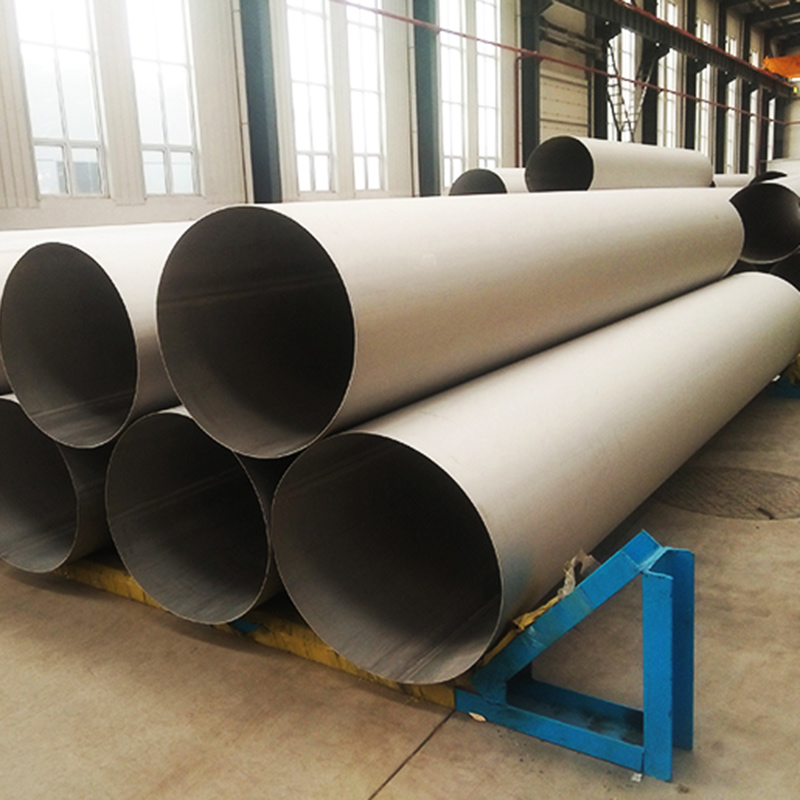

Iipayipi ezifakwe ngentsimbi engagqwaliyo zizinto ezibalulekileyo kumacandelo amaninzi ngenxa yokuqina kwazo, ukumelana nokugqwala, kunye nokuguquguquka kwazo. Ezi pipes zenziwe ngenkqubo yokudityaniswa, zidibanisa amaphepha entsimbi engagqwaliyo okanye imicu ukuze zenze iityhubhu ze-cylindrical. Nantsi inkcazo epheleleyo yeepayipi ezifakwe ngentsimbi engagqwaliyo:

Izixhobo kunye namaBanga:

● Uthotho lwe-304 kunye ne-316: Iiklasi zentsimbi engagqwaliyo ezisetyenziswa ngokubanzi.

● 310/S kunye ne-310H: Intsimbi engagqwaliyo enganyangekiyo kubushushu obuphezulu yokusetyenziswa kwesithando somlilo kunye ne-heat-exchange.

● 321 kunye ne-321H: Amanqanaba angamelani nobushushu afanelekileyo kwiindawo ezinobushushu obuphezulu.

● 904L: I-alloy enganyangekiyo kakhulu kwindalo enoburhalarhume.

● S31803: Intsimbi engenasici ephindwe kabini, enika amandla kunye nokumelana nokugqwala.

Inkqubo yoMveliso:

● Ukuwelda ngoMbane (EFW): Kule nkqubo, umthungo othe tyaba uyawelda ngokusebenzisa amandla ombane kwi-welding arc.

● Ukuwelda kwe-Arc engaphantsi komhlaba (SAW): Apha, ukuwelda kwenziwa ngokunyibilikisa imiphetho nge-arc eqhubekayo efakwe kwi-flux.

● Ukuwelda kwe-High-Frequency Induction (HFI): Le ndlela isebenzisa imisinga ye-high-frequency ukwenza umthungo we-weld kwinkqubo eqhubekayo.

Iingenelo:

● Ukumelana Nokugqwala: Iyamelana noluhlu olubanzi lweendaba ezigqwalayo kunye neendawo ezingqongileyo.

● Amandla: Amandla aphezulu oomatshini aqinisekisa ukuthembeka kwesakhiwo.

● Ukuguquguquka: Ifumaneka ngobukhulu obahlukeneyo, amanqanaba, kunye nokugqitywa ukuze ilungele usetyenziso olwahlukeneyo.

● Ucoceko: Lufanelekile kumashishini aneemfuno ezingqongqo zococeko.

● Ukuphila ixesha elide: Ihlala ixesha elide ngendlela emangalisayo, nto leyo ebangela ukuba isebenze ixesha elide.

Ngamafutshane, iipayipi ezifakwe intsimbi engagqwaliyo zizinto ezibalulekileyo kumashishini onke, zibonelela ngokuqina, ukumelana nokugqwala, kunye nokuguquguquka kwiindlela ezahlukeneyo zokusetyenziswa. Ukukhetha ngokufanelekileyo umgangatho, indlela yokuvelisa, kunye nokunamathela kwimigangatho yoshishino kubalulekile ekuqinisekiseni ukusebenza kakuhle kunye nokhuseleko lweenkqubo zeepayipi ezifakwe intsimbi.

Iinkcukacha

| I-ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njl.njl.... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njl... |

| I-DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njl... |

| I-JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB njl.njl.... |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Intsimbi engagqwaliyo yase-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Intsimbi engagqwali ephindwe kabini:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetyenziswa:Amashishini okuvelisa izixhobo zePetroleum, iiKhemikhali, igesi yendalo, amandla ombane kunye nezixhobo zoomatshini. |

| DN mm | NB Intshi | OD mm | I-SCH40S mm | I-SCH5S mm | I-SCH10S mm | I-SCH10 mm | I-SCH20 mm | I-SCH40 mm | I-SCH60 mm | XS/80S mm | I-SCH80 mm | I-SCH100 mm | I-SCH120 mm | I-SCH140 mm | I-SCH160 mm | I-SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| Ububanzi bodonga lombhobho obuyi-DN 1000mm nangaphezulu kufuneka bulungiselelwe wena | ||||||||||||||||

Imigangatho kunye neBanga

| Umgangatho | Amanqanaba eNsimbi |

| I-ASTM A312/A312M: Iipayipi ze-Austenitic Stainless Steel ezingasebenzi kakuhle, ezidityanisiweyo, nezibandayo kakhulu | 304, 304L, 310S, 310H, 316, 316L, 321, 321H njl.njl... |

| I-ASTM A269: Iityhubhu zentsimbi engagqwaliyo ezidityanisiweyo nezingenamthungo zenkonzo eqhelekileyo | TP304, TP304L, TP316, TP316L, TP321.TP347 njl... |

| I-ASTM A249: Ibhoyila yentsimbi ye-Austenitic edityanisiweyo, i-Superheater, i-Heat-Exchanger, kunye nee-Condenser Tubes | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| I-ASTM A269: Iityhubhu zentsimbi engagqwaliyo ezingenamthungo nezidibeneyo ezinobubanzi obuncinci | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| I-ASTM A270: Iityhubhu zokucoca ze-Austenitic kunye ne-Ferritic/Austenitic ezingenamthungo nezidibeneyo | Amanqanaba e-Austenitic Stainless Steel: 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 Amanqanaba eNtsimbi Engagqwaliyo yeFerritic/Austenitic (Duplex): S31803, S32205 |

| I-ASTM A358/A358M: Iimfuneko zePipe yeNsimbi ye-Austenitic eWelded kwiNdawo ezishushu kakhulu, ezixinezelekileyo, nezinobumdaka | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| I-ASTM A554: Iityhubhu zoomatshini zentsimbi engagqwaliyo ezidityanisiweyo, ezisetyenziswa rhoqo kwizicelo zesakhiwo okanye zokuhombisa | 304, 304L, 316, 316L |

| I-ASTM A789: Iityhubhu zentsimbi engagqwaliyo ze-ferritic/austenitic ezingenamthungo nezidibeneyo zenkonzo eqhelekileyo | S31803 (Intsimbi engagqwaliyo yeDuplex) I-S32205 (intsimbi engagqwaliyo yeDuplex) |

| I-ASTM A790: Umbhobho wentsimbi engenamthungo nedibeneyo ye-ferritic/austenitic yenkonzo yokubola ngokubanzi, inkonzo yobushushu obuphezulu, kunye nemibhobho yentsimbi engenamthungo ephindwe kabini. | S31803 (Intsimbi engagqwaliyo yeDuplex) I-S32205 (intsimbi engagqwaliyo yeDuplex) |

| EN 10217-7: iipayipi zentsimbi engagqwali ezitshixiweyo Iimfuno zokwenziwa ezisemgangathweni zaseYurophu. | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 njl. njl.... |

| I-DIN 17457: Umgangatho waseJamani osetyenziselwa ukwenza imibhobho edibeneyo yentsimbi engagqwaliyo | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 njl. njl.... |

| I-JIS G3468: Umgangatho wezoShishino waseJapan ochaza iimfuno zokwenziwa kwemibhobho yentsimbi engagqwali edityanisiweyo. | I-SUS304, i-SUS304L, i-SUS316, i-SUS316L, i-SUS329J3L njl... |

| GB/T 12771: Umgangatho weSizwe waseTshayina osetyenziselwa iimfuno zokwenziwa kwemibhobho edibeneyo yentsimbi engagqwaliyo. | 06Cr19Ni10, 022Cr19Ni1, 06Cr17Ni12Mo2, 022Cr22Ni5Mo3N |

| Intsimbi engagqwaliyo yase-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Intsimbi engagqwaliyo ephindwe kabini:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetyenziswa: I-Petroleum, iKhemikhali, igesi yendalo, umbane kunye namashishini okuvelisa izixhobo zoomatshini. | |

Ulawulo lwemeko

Ukuhlolwa kwezinto eziluhlaza, Uhlalutyo lweekhemikhali, Uvavanyo lwemishini, Uhlolo olubonakalayo, Uvavanyo lobungakanani, Uvavanyo lokugoba, Uvavanyo lwempembelelo, Uvavanyo lokugqwala oluphakathi kweegranular, Uvavanyo olungonakalisiyo (UT, MT, PT) Inkqubo yokuWelda, Uhlalutyo lweMicrostructure, Uvavanyo lokuFlaring kunye nokuThabatha, Uvavanyo loBulukhuni, Uvavanyo loxinzelelo, Uvavanyo lomxholo weFerrite, Uvavanyo lweMetallography, Uvavanyo lokugqwala, Uvavanyo lwangoku lwe-Eddy, Uvavanyo lweTyuwa, Uvavanyo lokuxhathisa ukugqwala, Uvavanyo lokungcangcazela, Uvavanyo lokugqwala, Uvavanyo lokupeyinta kunye nokugquma, Uhlolo lwamaxwebhu…..

Ukusetyenziswa kunye neSicelo

Iipayipi ezifakwe ngentsimbi engagqwaliyo zisetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yeempawu zazo ezibalaseleyo kunye nokuguquguquka kwazo. Ezi payipi zisetyenziswa kwiintlobo ngeentlobo zezicelo, ziqhutywa kukuqina kwazo, ukumelana nokugqwala, kunye nokufaneleka kwiindawo ezahlukeneyo. Ezinye zeendawo eziphambili zokusetyenziswa kunye nokusetyenziswa kweepayipi ezifakwe ngentsimbi engagqwaliyo ziquka:

● Ukusetyenziswa kwemizi-mveliso: Kuxhaphakile kwimizi-mveliso yeoyile, igesi, i-petrochemical, kunye neyombane ngenxa yokumelana nokugqwala.

● Ulwakhiwo: Lusetyenziswa kwimibhobho yamanzi, kubonelelo lwamanzi, nakwizakhiwo ngenxa yokuqina kwazo nokuhlala ixesha elide.

● Ishishini Lokutya: Libalulekile ekuhambiseni ukutya neziselo, ukuhlangabezana nemigangatho yococeko.

● Iimoto: Zisebenza kwiinkqubo zokukhupha umoya kunye neendawo ezakhiweyo, zinyamezela iimeko ezinzima.

● Ezonyango: Zisetyenziswa kwizixhobo zonyango nakwimibhobho yokucoca, zibeka phambili ucoceko.

● Ezolimo: Kwinkqubo zokunkcenkceshela ezimelana nokugqwala, ukuqinisekisa ukusasazwa kwamanzi ngokufanelekileyo.

● Unyango Lwamanzi: Ifanelekile ukuhambisa amanzi acociweyo nakhutshiweyo ityuwa.

● Ulwandle: Lumelana nokugqwala kwamanzi anetyuwa, lusetyenziswa kakhulu kwiinqanawa nakwiindawo ezikufutshane nolwandle.

● Amandla: Ukuthutha ulwelo kwicandelo lamandla, kuquka igesi yendalo kunye neoyile.

● Intlama kunye nePhepha: Zibalulekile ekuhambiseni iikhemikhali kunye nolwelo kwinkqubo yokuvelisa.

Ngamafutshane, iipayipi ezifakwe intsimbi engagqwaliyo zisebenza njengezinto ezibalulekileyo kumashishini amaninzi kunye nokusetyenziswa kwazo. Ukumelana nokugqwala, amandla oomatshini, kunye nokukwazi ukuhlangabezana neemfuno ezingqongqo kuzenza zibe yimfuneko kwiziseko zophuhliso zanamhlanje, iinkqubo zoshishino, kunye namacandelo ahlukeneyo akhethekileyo.

Ukupakisha kunye nokuthumela

Imibhobho yentsimbi engagqwaliyo iyapakishwa kwaye ithunyelwe ngononophelo olukhulu ukuqinisekisa ukhuseleko lwayo ngexesha lokuhamba. Nantsi inkcazo yenkqubo yokupakisha nokuthumela:

Ukupakisha:

● Ukwaleka Okukhuselekileyo: Ngaphambi kokupakisha, imibhobho yentsimbi engagqwaliyo idla ngokugqunywa ngomaleko weoyile okanye ifilimu yokukhusela ukuthintela ukugqwala kunye nomonakalo womphezulu.

● Ukubopha: Imibhobho enobukhulu obufanayo kunye neenkcukacha ezifanayo ihlanganiswa ngononophelo. Ibotshelelwa kusetyenziswa imitya, iintambo, okanye iibhanti zeplastiki ukuthintela intshukumo ngaphakathi kwebhanti.

● Ii-End Caps: Ii-end caps zeplastiki okanye zesinyithi zibekwe kuzo zombini iziphelo zemibhobho ukuze zikhuseleke ngakumbi kwiziphelo zemibhobho kunye nemisonto.

● Ukugquma kunye nokugquma: Izinto zokugquma ezifana ne-foam, i-bubble wrap, okanye i-corrugated cardboard zisetyenziselwa ukubonelela ngokugquma kunye nokuthintela umonakalo ngexesha lokuthuthwa.

● Iibhokisi okanye iibhokisi zomthi: Kwezinye iimeko, imibhobho ingapakishwa kwiibhokisi zomthi okanye iibhokisi ukuze inike ukhuseleko olongezelelweyo kumandla angaphandle kunye nokuphathwa.

Ukuhambisa ngenqanawe:

● Indlela Yokuthutha: Iipayipi zentsimbi engagqwaliyo zihlala zithunyelwa kusetyenziswa iindlela ezahlukeneyo zokuthutha ezifana neelori, iinqanawa, okanye uthutho lweenqwelo-moya, kuxhomekeke kwindawo oya kuyo kunye nongxamiseko.

● Ukufakwa kwiikhonteyina: Iipayipi zinokufakwa kwiikhonteyina zokuthutha impahla ukuqinisekisa ukuba izinto zihamba ngendlela ekhuselekileyo necwangcisiweyo. Oku kukwakhusela kwiimeko zemozulu kunye nezinto ezingcolisayo zangaphandle.

● Ukubhala iilebheli kunye namaxwebhu: Iphakheji nganye ibhalwe iinkcukacha ezibalulekileyo, kubandakanya iinkcukacha, ubungakanani, imiyalelo yokuphatha, kunye neenkcukacha zendawo ekuyiwa kuyo. Amaxwebhu okuthumela alungiselelwe ukususwa kwempahla kunye nokulandelwa kwempahla.

● Ukuthobela iMithetho yezeMali: Kwimpahla ethunyelwa kwamanye amazwe, onke amaxwebhu ayimfuneko yezemali alungiselelwe ukuqinisekisa ukuba impahla ifika kakuhle kwindawo ekuyiwa kuyo.

● Ukubopha Okukhuselekileyo: Ngaphakathi kwisithuthi okanye kwisikhongozeli, imibhobho ibotshelelwe ngokukhuselekileyo ukuthintela intshukumo nokunciphisa umngcipheko wokonakala ngexesha lokuhamba.

● Ukulandelela Nokubeka Esweni: Iinkqubo zokulandelela eziphambili zingasetyenziswa ukujonga indawo kunye nemeko yokuthunyelwa ngexesha langempela.

● I-inshorensi: Ngokuxhomekeke kwixabiso lomthwalo, i-inshorensi yokuthumela impahla ingafunyanwa ukuze ihlawule ilahleko okanye umonakalo onokubakho ngexesha lokuhamba.

Ngamafutshane, iipayipi zentsimbi engagqwaliyo esizenzileyo ziya kupakishwa ngamanyathelo okukhusela kwaye zithunyelwe kusetyenziswa iindlela zokuthutha ezithembekileyo ukuqinisekisa ukuba zifika kwindawo eziya kuyo zikwimeko efanelekileyo. Iinkqubo ezifanelekileyo zokupakisha nokuthumela zinegalelo ekugqibeleleni nasekusemgangathweni kweepayipi ezihanjiswayo.