Ingcaciso yeMveliso

Iikheyisi kunye neetyhubhu ezisetyenziswa kakhulu kwi-oyile negesi, iikheyisi kunye neetyhubhu zizinto ezibalulekileyo kwishishini leoyile negesi ezisetyenziselwa ukukhutshelwa kunye nokuthuthwa kwee-hydrocarbons (ioyile kunye negesi yendalo) ukusuka kwiindawo zokugcina amanzi ezingaphantsi komhlaba ukuya kumphezulu. Zidlala indima ebalulekileyo ekuqinisekiseni ukhuseleko, ukuthembeka, kunye nokusebenza kakuhle kwemisebenzi yokugrumba kunye nemveliso.

Ityhubhu luhlobo lombhobho osetyenziselwa ukudlulisa ioyile ekrwada kunye negesi yendalo ukusuka kumaleko weoyile okanye kumaleko wegesi ukuya emhlabeni emva kokuba kugqityiwe ukugrumba. Ityhubhu ivumela uxinzelelo oluveliswayo ngexesha lenkqubo yokukhupha. Ityhubhu iveliswa ngendlela efanayo nekheyisi, kodwa inkqubo ebizwa ngokuba yi "upsetting" iyadingeka ukuze ijiye umbhobho wetyhubhu.

I-casing isetyenziselwa ukukhusela imingxuma yemigodi eyembiwe emhlabeni ukuze kufunyanwe ioyile. Isetyenziswa ngokufanayo nombhobho wokubhola, imibhobho yemigodi yeoyile ikwavumela uxinzelelo lwe-axial tension, ngoko ke kufuneka intsimbi enamandla aphezulu. Ii-casing ze-OCTG ziipayipi ezinkulu ezinobubanzi ezifakwe isamente kumngxuma wemigodi.

Iinkcukacha

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| I-API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A106: GR.A, GR.B, GR.C |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| I-ASTM A333: Ibanga 1, Ibanga 3, Ibanga 4, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9. Ibanga 10, Ibanga 11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| I-DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-JIS G3454: STPG 370, STPG 410 |

| I-JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Uluhlu lwe-ISO/API Steel Casing

| Iilebhelia | Ngaphandle ububanzi D mm | Igama eliqingqiweyo umgca ubunzimab, c Imigaqo-nkqubo kunye neMigqaliselo kg/m | Udonga ubukhulu t mm | Uhlobo lokuphela kwento | ||||||||

| 1 | 2 | H40 | J55 K55 | I-M65 | L80 C95 | N80 Uhlobo 1, Q | C90 I-T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS I-PSB I-PSLB — — | PS I-PSB I-PLB I-PLB — | — — I-PLB I-PLB — | — — I-PLB I-PLB — | — — I-PLB I-PLB — | — — I-PLB I-PLB I-PLB | — — — — I-PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS I-PSLB I-PSLBE — — — — | PS I-PSLB I-PLB I-PLB I-PLB — — | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — — I-PLBE I-PLB I-PLB I-PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS I-PSLBE I-PSLBE | PS I-PSLB I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLBE — — — — — — — | I-PLBE I-PLBE I-PLBE | I-PLBE I-PLBE I-PLBE P P P P P P P | I-PLBE I-PLBE I-PLBE | — — — — I-PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | I-PSLB I-PSLBE — | I-PSLB I-PLB I-PLB — | — I-PLBE I-PLBE I-PLBE | — I-PLBE I-PLBE I-PLBE | — I-PLBE I-PLBE I-PLBE | — I-PLBE I-PLBE I-PLBE | — — I-PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS I-PSLBE I-PSLBE — — — — — — — — — | — PS I-PLB I-PLB I-PLB I-PLB — — — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE P P P P P | — — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE — — — — — | — — — — — — I-PLBE I-PLBE — — — — — |

| Jonga amanqaku ekupheleni kwetheyibhile. | ||||||||||||

| Iilebhelia | Ngaphandle ububanzi D mm | Igama eliqingqiweyo umgca ubunzimab, c Imigaqo-nkqubo kunye neMigqaliselo kg/m | Udonga ubukhulu t mm | Uhlobo lokuphela kwento | ||||||||

| 1 | 2 | H40 | J55 K55 | I-M65 | L80 C95 | N80 Uhlobo 1, Q | C90 I-T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | I-PSLBE | I-PSLB I-PLB I-PLB | I-PLBE I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB | I-PLBE I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB | I-PLBE I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB P P | I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB | I-PLBE I-PLB I-PLB I-PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — I-PSLBE I-PSLBE — — — | PS PS I-PSLB I-PSLB I-PLB — — | — — — I-PLBE I-PLBE I-PLBE I-PLBE | — — — I-PLBE I-PLBE I-PLBE I-PLBE | — — — I-PLBE I-PLBE I-PLBE I-PLBE | — — — — I-PLBE I-PLBE I-PLBE | — — — — — — I-PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — I-PSLB I-PSLBE — — — — — — — — | — I-PSLB I-PSLB I-PLB I-PLB — — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLB — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLB — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLB P P P P | — — — I-PLBE I-PLBE I-PLBE I-PLB — — — — | — — — — I-PLBE I-PLBE I-PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | I-PSB I-PSBE I-PSBE | I-PSB I-PSB I-PSB I-PSB | I-PSBE I-PSBE | I-PSBE I-PSBE | I-PSBE I-PSBE I-PSBE I-PSB P P P | I-PSBE I-PSBE I-PSBE I-PSB | I-PSBE I-PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | I-PSB I-PSB I-PSB — — | I-PSB I-PSB I-PSB — — | — — I-PSB P P | — — I-PSB P P | — — I-PSB P P | — — I-PSB P P | — — I-PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — I-PSB I-PSB I-PSB — | — I-PSB I-PSB I-PSB — | — — — I-PSB I-PSB | — — — I-PSB I-PSB | — — — I-PSB I-PSB | — — — I-PSB I-PSB | — — — — I-PSB |

| Jonga amanqaku ekupheleni kwetheyibhile. | ||||||||||||

| Iilebhelia | Ngaphandle ububanzi D mm | Igama eliqingqiweyo umgca ubunzimab, c Imigaqo-nkqubo kunye neMigqaliselo kg/m | Udonga ubukhulu t mm | Uhlobo lokuphela kwento | ||||||||

| 1 | 2 | H40 | J55 K55 | I-M65 | L80 C95 | N80 Uhlobo 1, Q | C90 I-T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | I-PSB I-PSB P | I-PSB I-PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | I-PSB | I-PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | I-PSL — — | I-PSLB I-PSLB I-PSLB | I-PSLB I-PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Isiphelo esingenanto, S = Umsonto omfutshane ongqukuva, L = Umsonto omde ongqukuva, B = Umsonto we-Buttress, E = Umgca ogqithisileyo. | ||||||||||||

| ♦ Iilebheli zezolwazi kunye noncedo eku-odoleni. ♦ Izixa eziziinombolo ezithe tyaba, ezifakwe imisonto nezidibeneyo (umqolo wesi-2) ziboniswa ukuze zifumane ulwazi kuphela. ♦ Ubuninzi beentsimbi ze-martensitic chromium (iintlobo ze-L80 9Cr kunye ne-13Cr) zahlukile kwiintsimbi ze-carbon. Ubunzima obubonisiweyo abuchanekanga kwiintsimbi ze-martensitic chromium. I-mass correction factor ye-0,989 ingasetyenziswa. | ||||||||||||

| Iilebheli | Ububanzi obungaphandle D mm | Isiphelo esingenanto esithe tyaba ubunzima kg/m | Ubukhulu bodonga t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Uluhlu lweetyhubhu zentsimbi ze-ISO/API

| Iilebheli | Ngaphandle ububanzi D mm | Uluhlu oluqhelekileyo izihlwelea, b | Udonga tyebile- ubukho t mm | Uhlobo lokugqiba kokuphelac | |||||||||||

| Akukho- khathazekile Imigaqo-nkqubo kunye neMigqaliselo kg/m | Ulwandiso. khathazekile Imigaqo-nkqubo kunye neMigqaliselo kg/m | Integ. ijoyinti kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Imigaqo-nkqubo kunye neMigqaliselo | EU Imigaqo-nkqubo kunye neMigqaliselo | IJ | H40 | J55 | L80 | N80 Uhlobo 1, Q | C90 | I-T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI I-PNUI PU — — | PI I-PNUI PU — — | — I-PNUI PU P P | — I-PNUI PU — — | — I-PNUI PU P P | — I-PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN I-PNU | PN I-PNU | PN I-PNU I-PNU P PU | PN I-PNU I-PNU — — | PN I-PNU I-PNU P PU | PN I-PNU I-PNU P PU | I-PNU I-PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | I-PNU — — | I-PNU — — | I-PNU I-PNU I-PNU PU | I-PNU I-PNU I-PNU — | I-PNU I-PNU I-PNU PU | I-PNU I-PNU I-PNU PU | I-PNU I-PNU I-PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN I-PNU PN — — — — | PN I-PNU PN — — — — | PN I-PNU PN I-PNU P P P | PN I-PNU PN I-PNU — — — | PN I-PNU PN I-PNU P P P | PN I-PNU PN I-PNU P P P | — I-PNU — I-PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | I-PNU | I-PNU | I-PNU P P P P P P | I-PNU — — — — — — | I-PNU P P P P P P | I-PNU P P P P P P | |||

| P = Isiphelo esingenanto, N = Intambo engaphazamisekanga nedibeneyo, U = Intambo yangaphandle ephazamisekileyo nedibeneyo, I = Ilungu elidibeneyo. | |||||||||||||||

| ♦ Ubunzima obuqhelekileyo obuhambelanayo, imisonto kunye nokudibanisa (umqolo wesi-2, 3, 4) kuboniswa ngolwazi kuphela. ♦ Ubuninzi beentsimbi ze-martensitic chromium (iintlobo ze-L80 9Cr kunye ne-13Cr) zahlukile kwiintsimbi ze-carbon. Ubunzima obubonisiweyo abuchanekanga kwiintsimbi ze-martensitic chromium. I-mass correction factor ye-0,989 ingasetyenziswa. ♦ Iityhubhu ezingaphazamisekiyo ziyafumaneka ngee-couplings eziqhelekileyo okanye ii-couplings ezikhethekileyo ze-bevel. Iityhubhu zangaphandle ziyafumaneka ngee-couplings eziqhelekileyo, ze-bevel ekhethekileyo, okanye ze-clearance ezikhethekileyo. | |||||||||||||||

Imigangatho kunye neBanga

Ikheyisi kunye netyhubhu Amanqanaba aqhelekileyo:

I-API 5CT J55,K55,L80, N80,P110, C90, T95, H40

Iziphelo ze-API 5CT casing kunye nepayipi:

(STC) Ibhokisi yemisonto emfutshane engqukuva

(LC) Ibhokisi yemisonto ende ejikelezayo

(BC) Ibhokisi yemisonto ye-Buttress

(XC)Ibhokisi enomda ogqithisileyo

(NU) Imibhobho engaphazamisekiyo

(EU) Iipayipi zangaphandle eziphakanyisiweyo

(IJ) Imibhobho edibeneyo yamalungu

Ibhokisi kunye neetyhubhu kufuneka zihanjiswe ngokwemiqhagamshelo engentla kunye nomgangatho weMigangatho ye-API5CT / API.

Ulawulo lwemeko

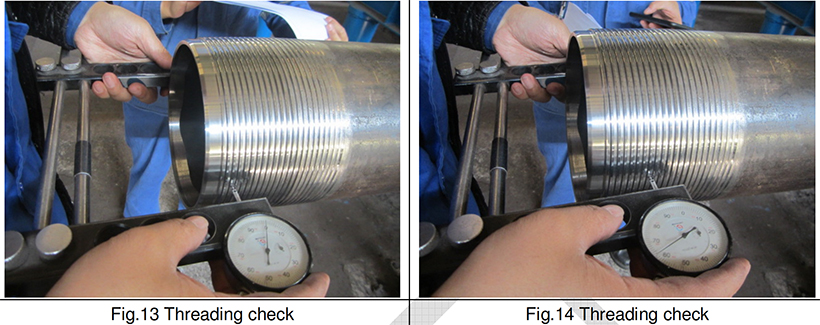

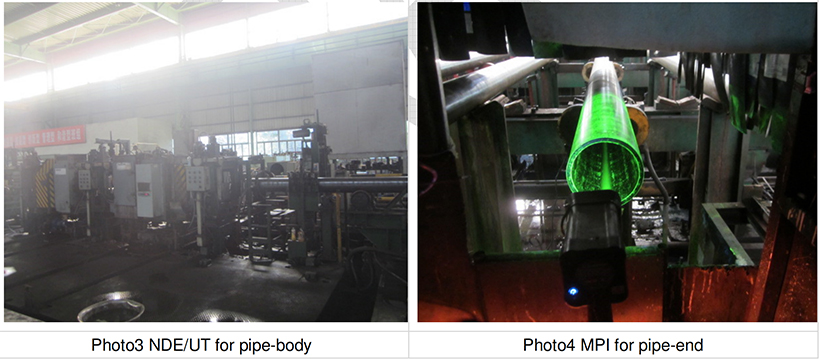

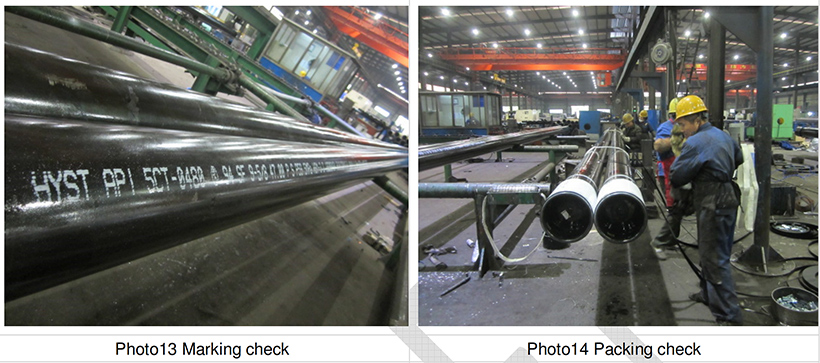

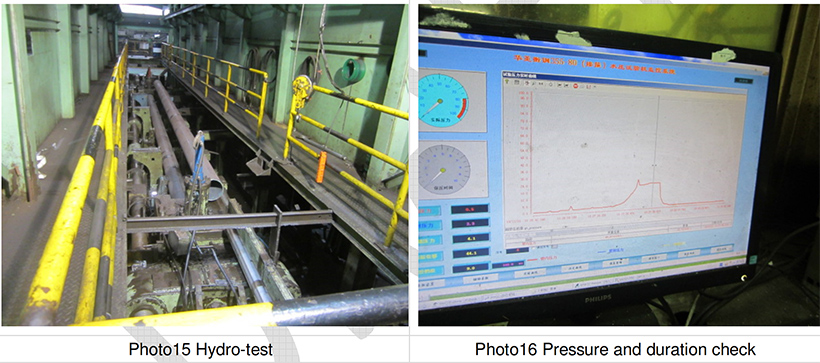

Ukujonga Izinto Ezingavulwanga, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Uvavanyo loxinzelelo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lwempembelelo, Uvavanyo lwe-DWT, Uvavanyo lwe-NDT, Uvavanyo lwe-Hydrostatic, Uvavanyo loBulukhuni…..

Ukumakisha, Ukupeyinta ngaphambi kokuhanjiswa.

Ukupakisha kunye nokuthumela

Indlela yokupakisha imibhobho yentsimbi ibandakanya ukucoca, ukuhlanganisa, ukusonga, ukubopha, ukubopha, ukulebhelisha, ukufaka iipalethi (ukuba kuyimfuneko), ukufaka kwiikhonteyina, ukuvala, ukuthutha, kunye nokukhupha izinto. Iintlobo ngeentlobo zemibhobho yentsimbi kunye nezixhobo ezineendlela ezahlukeneyo zokupakisha. Le nkqubo ibanzi iqinisekisa ukuba imibhobho yentsimbi ithunyelwa kwaye ifika kwindawo eya kuyo ikwimeko efanelekileyo, ilungele ukusetyenziswa kwayo.

Ukusetyenziswa kunye neSicelo

Iipayipi zentsimbi zisebenza njengomqolo wobunjineli banamhlanje bemizi-mveliso nobokwakha, zixhasa uluhlu olubanzi lwezicelo ezinegalelo kuphuhliso lwentlalo kunye noqoqosho kwihlabathi liphela.

Iipayipi zentsimbi kunye nezixhobo esizivelisileyo zeWomic Steel zisetyenziswa kakhulu kwimibhobho yepetroli, igesi, amafutha kunye namanzi, iiprojekthi zokwakha izibuko lolwandle kunye nokwakha, ukugrumba, iiprojekthi zokwakha intsimbi, ukupakisha kunye neebhulorho, kunye neetyhubhu zentsimbi ezichanekileyo zokuvelisa i-conveyor roller, njl.njl.