Ingcaciso yeMveliso

Umnciphisi:

Isixhobo sokunciphisa imibhobho yentsimbi sisebenza njengecandelo elibalulekileyo lombhobho, sivumela utshintsho olungenamthungo ukusuka kubukhulu obukhulu ukuya kobuncinci ngokuhambelana nemigaqo yobubanzi bangaphakathi.

Zimbini iintlobo eziphambili zee-reducers ezikhoyo: ezixineneyo nezingaqhelekanga. Ii-Concentric reducers zisebenza ekunciphiseni ubungakanani be-bore obulinganayo, ziqinisekisa ukulungelelaniswa kwemigca ephakathi yepayipi edibeneyo. Olu lwakhiwo lufanelekile xa ukugcina amazinga okuhamba afanayo kubalulekile. Ngokwahlukileyo koko, ii-eccentric reducers zizisa i-offset phakathi kwemigca ephakathi yepayipi, zilungiselela iimeko apho amanqanaba olwelo afuna ukulingana phakathi kwepayipi ephezulu nesezantsi.

Ukunciphisa okungaqhelekanga

I-Concentric Reducer

Izinciphisi zidlala indima yokuguqula izinto ekucwangcisweni kwemibhobho, zinceda ekutshintsheni okutyibilikayo phakathi kwemibhobho enobukhulu obahlukeneyo. Oku kuphucula ukusebenza kakuhle kwenkqubo iyonke kunye nokusebenza kwayo.

Ingqiniba:

Ingqiniba yombhobho wentsimbi inendima ebalulekileyo kwiinkqubo zemibhobho, inceda utshintsho kwicala lokuhamba kolwelo. Isetyenziswa ekudibaniseni imibhobho enobubanzi obufanayo okanye obahlukeneyo, iqondisa ngokufanelekileyo ukuhamba kwindlela efunekayo.

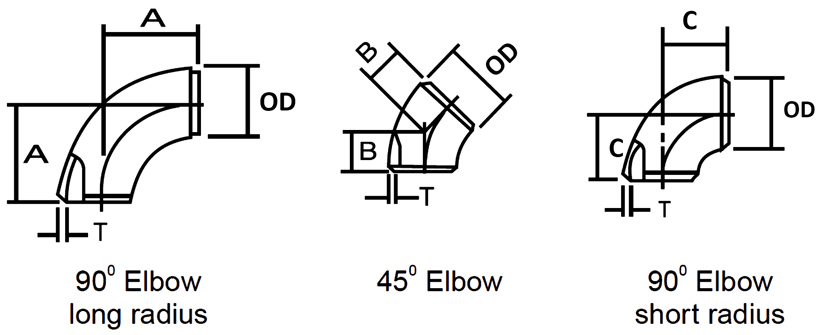

Iingqiniba zihlulwe ngokwezinga lokutshintsha kolwelo oluvela kwimibhobho. Ii-engile eziqhelekileyo ziquka ii-degrees ezingama-45, ii-degrees ezingama-90, kunye nee-degrees ezili-180. Kwizicelo ezikhethekileyo, ii-engile ezifana nee-degrees ezingama-60 kunye nee-degrees ezili-120 ziyasetyenziswa.

Iingqiniba zahlulwe ngokwahlukeneyo ngokusekelwe kwirediyasi yazo xa kuthelekiswa nobubanzi bepayipi. I-Short Radius Elbow (SR elbow) inerediyasi elingana nobubanzi bepayipi, nto leyo eyenza ukuba ifaneleke kwiipayipi ezinoxinzelelo oluphantsi, ezinesantya esiphantsi, okanye kwiindawo ezixineneyo apho indawo ingena khona iphezulu. Ngokwahlukileyo koko, i-Long Radius Elbow (LR elbow), enerediyasi ephindwe kayi-1.5 kunobubanzi bepayipi, isetyenziswa kwiipayipi ezinoxinzelelo oluphezulu kunye nesantya sokuhamba kwamanzi aphezulu.

Iingqiniba zingahlulwa ngokweendlela zazo zokudibanisa imibhobho—i-Butt Welded Elbow, i-Socket Welded Elbow, kunye ne-Threaded Elbow. Olu tshintsho lubonelela ngokuguquguquka ngokusekelwe kuhlobo lwejoyinti olusetyenziswayo. Ngokwezinto eziphathekayo, iingqiniba zenziwe ngentsimbi engagqwaliyo, intsimbi yekhabhoni, okanye intsimbi ye-alloy, ezilungelelaniswa neemfuno zomzimba wevalvu ethile.

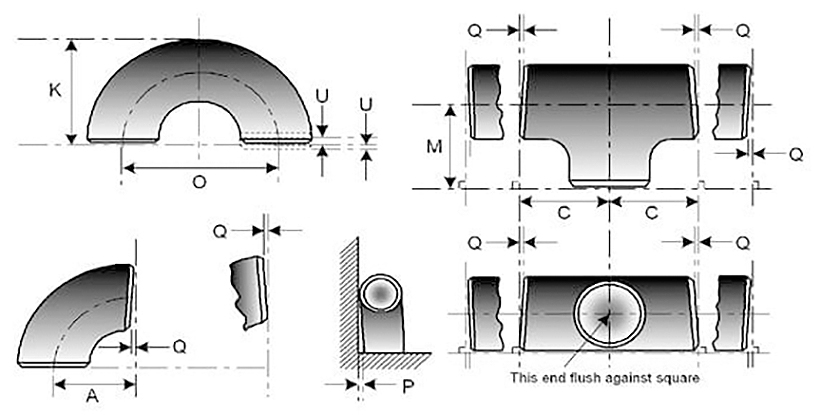

I-Tie:

Iintlobo zeSteel Pipe Tee:

● Ngokusekelwe kwiidayamitha zesebe kunye nemisebenzi:

● I-Equal Tie

● I-Tee Yokunciphisa (I-Tee Yokunciphisa)

Ngokusekelwe kwiintlobo zoQhagamshelo:

● I-Butt Weld Tee

● I-Socket Weld Tee

● I-Tie enemisonto

Ngokusekelwe kwiintlobo zezinto ezibonakalayo:

● I-Carbon Steel Pipe Tee

● I-Alloy Steel Tee

● I-T-Shirt yentsimbi engenasici

Izicelo zeSteel Pipe Tee:

● Ii-T-shirt zentsimbi zizixhobo ezisetyenziswa ngeendlela ezahlukeneyo ezisetyenziswa kumashishini ahlukeneyo ngenxa yokukwazi kwazo ukunxibelelana nokuqondisa ukuhamba kwamanzi kwiindlela ezahlukeneyo. Ezinye zezicelo eziqhelekileyo ziquka:

● Uthumelo lweoyile negesi: IiTee zisetyenziselwa ukwahlulahlula imibhobho yokuthutha ioyile negesi.

● Ukucocwa kwePetroleum neOyile: Kwiindawo zokucoca, ii-tee zinceda ukulawula ukuhamba kweemveliso ezahlukeneyo ngexesha leenkqubo zokucoca.

● Iinkqubo Zokucoca Amanzi: IiTee zisetyenziswa kwizityalo zokucoca amanzi ukulawula ukuhamba kwamanzi kunye neekhemikhali.

● Amashishini eeKhemikhali: IiTee zidlala indima ekucutshungulweni kweekhemikhali ngokulawula ukuhamba kweekhemikhali kunye nezinto ezahlukeneyo.

● Iityhubhu Zokucoca: Kwimizi-mveliso yokutya, yamayeza, nakwamanye amashishini, iityhubhu zokucoca zinceda ekugcineni imeko yococeko xa kuthuthwa ulwelo.

● Izikhululo zoMbane: IiTee zisetyenziswa kwiinkqubo zokuvelisa nokusasaza umbane.

● Oomatshini kunye nezixhobo: IiTee zihlanganiswe kwiimashini ezahlukeneyo zoshishino kunye nezixhobo zokulawula ulwelo.

● Izitshintshi zobushushu: IiTee zisetyenziswa kwiinkqubo zesitshintshi sobushushu ukulawula ukuhamba kolwelo olushushu nolubandayo.

Ii-tee zepayipi zentsimbi zizinto ezibalulekileyo kwiinkqubo ezininzi, zibonelela ngokuguquguquka nolawulo lokusasazwa kunye necala lolwelo. Ukukhethwa kwezinto kunye nohlobo lwe-tee kuxhomekeke kwizinto ezifana nohlobo lolwelo oluthuthwayo, uxinzelelo, ubushushu, kunye neemfuno ezithile zokusetyenziswa.

Isishwankathelo seSigqubuthelo sePipe yeNsimbi

Isigqubuthelo sepayipi yentsimbi, esikwabizwa ngokuba yiplagi yentsimbi, sisixhobo esisetyenziselwa ukugquma isiphelo sepayipi. Sinokudityaniswa siye esiphelweni sepayipi okanye sincamathiselwe kumsonto wangaphandle wepayipi. Izigqubuthelo zepayipi yentsimbi zisebenza ngenjongo yokugquma nokukhusela izihlanganisi zepayipi. Ezi zigqubuthelo ziza ngeemilo ezahlukeneyo, kuquka izigqubuthelo ze-hemispherical, elliptical, dish, kunye nezigqubuthelo ezingqukuva.

Iimilo zeeCaps eziNgqamza:

● Isiciko seHemispherical

● Isiciko se-Elliptical

● Isiciko sesitya

● Isiciko esingqukuva

Unyango loQhagamshelo:

Izivalo zisetyenziselwa ukunqumla utshintsho kunye noqhagamshelo kwiipayipi. Ukukhetha unyango loqhagamshelo kuxhomekeke kwiimfuno ezithile zesicelo:

● Uqhagamshelo lwe-Butt Weld

● Uqhagamshelo lweSocket Weld

● Uqhagamshelo olunemisonto

Izicelo:

Izigqubuthelo zokugqibela zineendlela ezahlukeneyo zokusetyenziswa kumashishini afana neekhemikhali, ulwakhiwo, iphepha, isamente, kunye nokwakha iinqanawa. Ziluncedo kakhulu ekudibaniseni imibhobho enobubanzi obahlukeneyo kunye nokubonelela ngomqobo wokukhusela ekupheleni kombhobho.

Iintlobo zeSteel Pipe Cap:

Iintlobo zoQhagamshelo:

● Isigqubuthelo sokuWelda esinamaqhuqhuva

● Isiciko seSocket Weld

● Iintlobo zezinto:

● Isiciko sePipe yentsimbi yeCarbon

● Isiciko sentsimbi engenasici

● I-Alloy Steel Cap

Isishwankathelo seMbhobho yeNsimbi

Ukugoba kwepayipi yentsimbi luhlobo lokufakelwa kwepayipi olusetyenziselwa ukutshintsha indlela yombhobho. Nangona kufana nengqiniba yombhobho, ukugoba kwepayipi kukude kwaye kudla ngokwenziwa ngokweemfuno ezithile. Ukugoba kwepayipi kuza ngobukhulu obahlukeneyo, kunye namanqanaba ahlukeneyo okugoba, ukuze kulungiselelwe ii-engile ezahlukeneyo zokujika kwimibhobho.

Iintlobo zokugoba kunye nokusebenza kakuhle:

Ukugoba kwe-3D: Ukugoba okune-radius ephindwe kathathu kunobubanzi bepayipi eqhelekileyo. Isetyenziswa rhoqo kwiipayipi ezinde ngenxa yokugoba kwayo okuthambileyo kunye nokutshintsha kwendlela esebenza kakuhle.

I-5D Bend: Le jika ine-radius ephindwe kahlanu kunobubanzi bepayipi eqhelekileyo. Inika utshintsho oluthambileyo kwicala, okwenza ifaneleke kwiipayipi ezinde ngelixa igcina ukusebenza kakuhle kokuhamba kolwelo.

Ukuhlawula utshintsho lweDigri:

Ukugoba kwe-6D kunye ne-8D: La magoba, ane-radii ephindwe kathandathu kwaye ephindwe kasibhozo kunobubanzi bombhobho oqhelekileyo ngokulandelelana, asetyenziselwa ukuhlawula utshintsho oluncinci kwicala lombhobho. Aqinisekisa ukuguquka kancinci kancinci ngaphandle kokuphazamisa ukuhamba kwamanzi.

Iingqiniba zemibhobho yentsimbi zizinto ezibalulekileyo kwiinkqubo zemibhobho, ezivumela utshintsho oluya kwicala ngaphandle kokubangela ukuxinana okukhulu okanye ukumelana nokuhamba kolwelo. Ukukhetha uhlobo lokugoba kuxhomekeke kwiimfuno ezithile zombhobho, kubandakanya ubungakanani botshintsho kwicala, indawo ekhoyo, kunye nesidingo sokugcina iimpawu zokuhamba kakuhle.

Iinkcukacha

| I-ASME B16.9: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi ye-Alloy |

| EN 10253-1: Intsimbi yekhabhoni, intsimbi engatyiwayo, intsimbi ye-alloy |

| I-JIS B2311: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi ye-Alloy |

| I-DIN 2605: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi ye-Alloy |

| GB/T 12459: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi ye-alloy |

Ubukhulu be-elbow yepayipi bugutyungelwe kwi-ASME B16.9. Jonga le theyibhile ingezantsi ukuze ufumane ubungakanani bobukhulu be-elbow ukusuka kwi-1/2″ ukuya kwi-48″.

| Ubungakanani bombhobho obizwa ngokuba yiNominal | IDAMETHA YANGAPHANDLE | IZIKO UKUYA PHELANA | ||

| Intshi. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 38 | 19 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

| Zonke iisayizi zikwi-mm | ||||

Ubungakanani bezixhobo zombhobho Ukunyamezela ngokwe-ASME B16.9

| Ubungakanani bombhobho obizwa ngokuba yiNominal | ZONKE IZIXHOBO | ZONKE IZIXHOBO | ZONKE IZIXHOBO | IINGQONDO NEZINTO EZINXINXI | UKUJONGA KWE-180 DEG | UKUJONGA KWE-180 DEG | UKUJONGA KWE-180 DEG | IZINCIPHISO |

IINKCUKACHA |

| I-NPS | OD eBevel (1), (2) | Isazisi Ekupheleni | Ubukhulu bodonga (3) | Ubukhulu obuvela embindini ukuya ekupheleni A,B,C,M | Ukusuka kwiziko ukuya kwiziko O | Ukubuyelana Ubuso K | Ulungelelwaniso lweeMpendulo U | Ubude obupheleleyo H | Ubude obupheleleyo E |

| ½ ukuya kwi-2½ | 0.06 | 0.03 | Akukho ngaphantsi kwe-87.5% yobukhulu obuqhelekileyo | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 ukuya kwi-3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 ukuya kwi-8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| 10 ukuya kwi-18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 20 ukuya kuma-24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 26 ukuya ku-30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| 32 ukuya kuma-48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 |

| Ubungakanani bombhobho obizwa ngokuba yi-NPS | Ukunyamezelana kwe-angular | Ukunyamezelana kwe-angular | Zonke izilinganiso zinikwe ngee-intshi. Ukunyamezelana kuyalingana kunye kwaye kuncitshiswe ngaphandle kokuba kuphawuliwe. |

|

| I-Angle Q engasebenziyo | Ngaphandle kwendiza P | (1) I-Out-of-round yimbumba yamaxabiso apheleleyo okongeza kunye nokunyamezelana okuncinci. (2) Olu hlengahlengiso alunakusebenza kwiindawo ezikufutshane zee-fittings ezenziweyo apho kufuneka ubukhulu bodonga obuphezulu ukuze kuhlangatyezwane neemfuno zoyilo lwe-ASME B16.9. (3) Ububanzi bangaphakathi kunye nobukhulu bodonga obuqhelekileyo eziphelweni kufuneka buchazwe ngumthengi. (4) Ngaphandle kokuba kuchazwe ngenye indlela ngumthengi, ezi meko zokunyamezela zisebenza kwi-nominal inside diameter, elingana nomahluko phakathi kwe-nominal outside diameter kunye ne-nominal wall thickness ephindwe kabini. |

| ½ ukuya kwi-4 | 0.03 | 0.06 | |

| 5 ukuya kwi-8 | 0.06 | 0.12 | |

| 10 ukuya kwi-12 | 0.09 | 0.19 | |

| 14 ukuya kwi-16 | 0.09 | 0.25 | |

| 18 ukuya kuma-24 | 0.12 | 0.38 | |

| 26 ukuya ku-30 | 0.19 | 0.38 | |

| 32 ukuya ku-42 | 0.19 | 0.50 | |

| 44 ukuya ku-48 | 0.18 | 0.75 |

Imigangatho kunye neBanga

| I-ASME B16.9: Izixhobo Zokuwelda Ezifakwe Kwizinqe Ezisefektri | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| I-EN 10253-1: Izixhobo zePipe zokuWelda ngeeButt-Icandelo 1: Intsimbi yekhabhoni eyenziweyo yokusetyenziswa ngokubanzi kwaye ngaphandle kweemfuno ezithile zovavanyo | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| I-JIS B2311: Izixhobo zePipe zokuWelda ngeeButt zentsimbi ezisetyenziswa rhoqo | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| I-DIN 2605: Izixhobo zePipe zokuWelda ngeeButt zentsimbi: Iingqiniba kunye nokugoba okuneNgxaki eNciphisiweyo | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| GB/T 12459: Izixhobo zePipe ezingenamthungo zokuWelda ngeeButt-Welding zentsimbi | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

Inkqubo yoMveliso

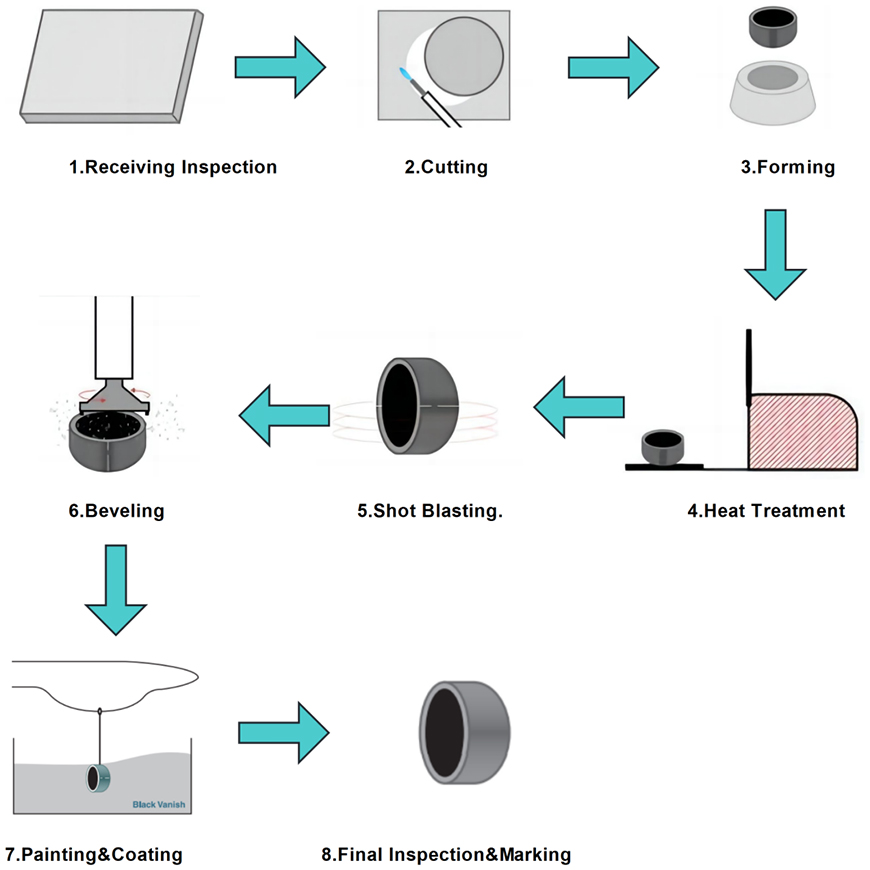

Inkqubo yokuVelisa iiCap

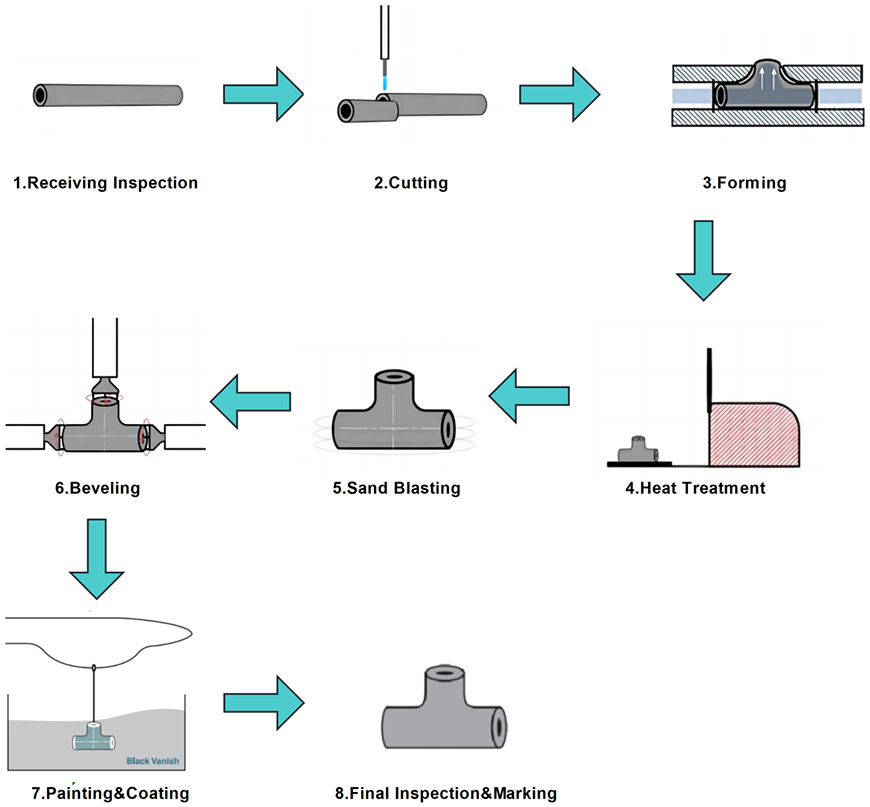

Inkqubo yokuvelisa i-Tee

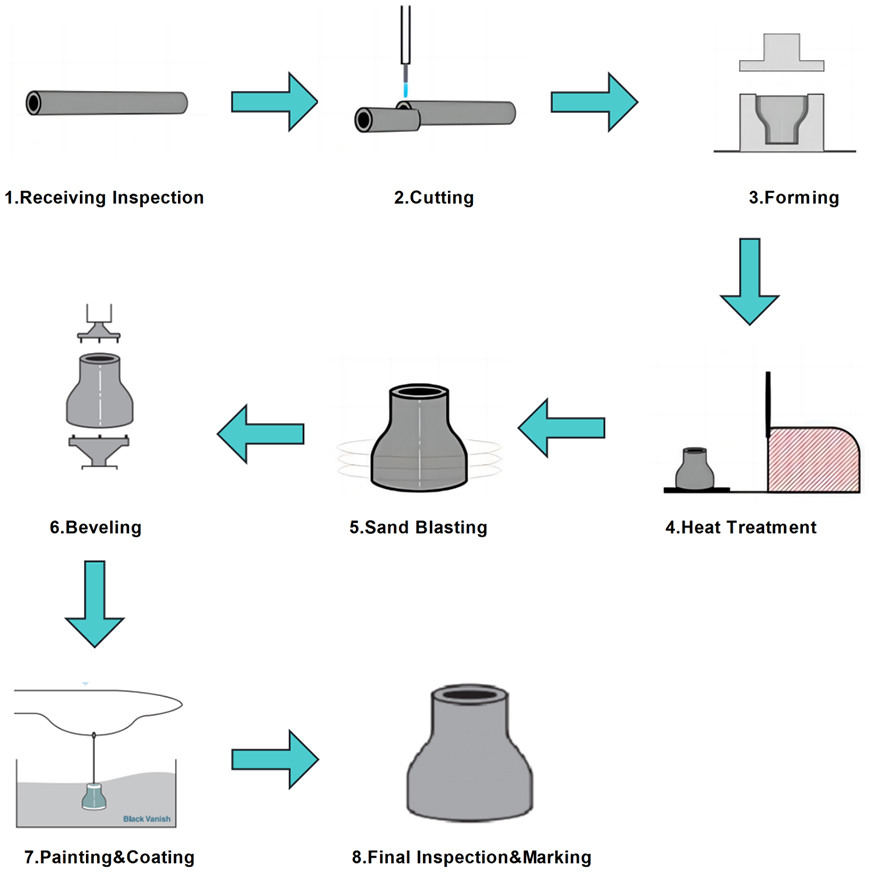

Inkqubo yoMveliso wokunciphisa

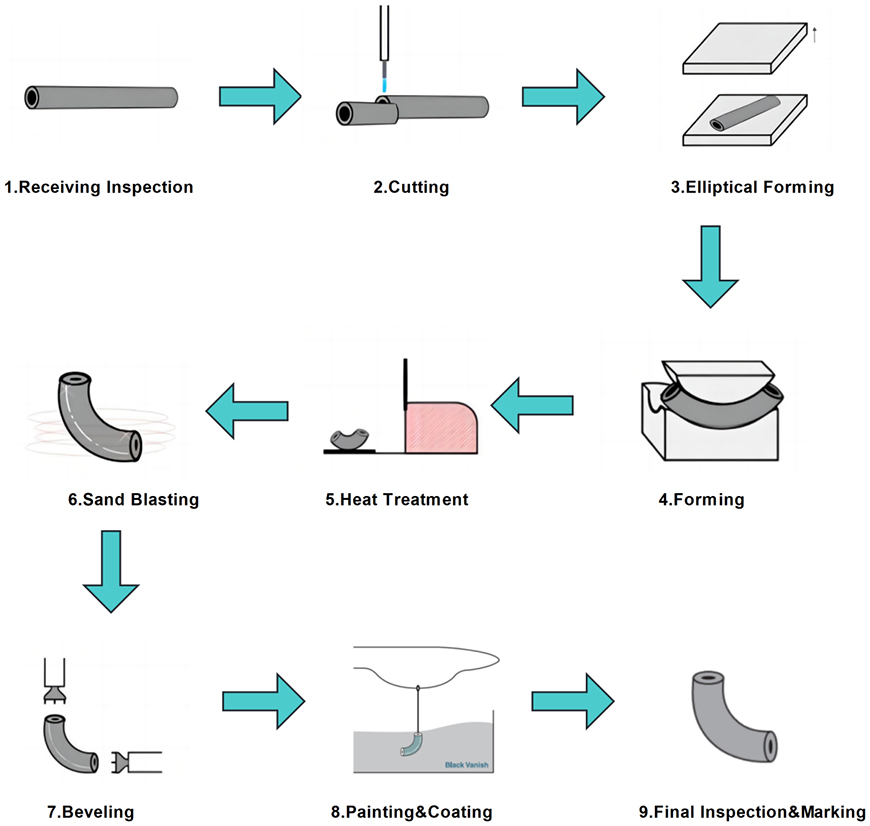

Inkqubo yokuvelisa i-Elbow

Ulawulo lwemeko

Ukujonga Izinto Eziluhlaza, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lweMpembelelo, Uvavanyo lwe-DWT, Uvavanyo olungonakalisiyo, Uvavanyo loBulukhuni, Uvavanyo loxinzelelo, Uvavanyo lokuvuza kwesihlalo, Uvavanyo lokusebenza kokuhamba kwamanzi, Uvavanyo lweTorque kunye neThrust, Uvavanyo lokupeyinta kunye nokufaka, Uhlolo lwamaxwebhu…..

Ukusetyenziswa kunye neSicelo

Ukujonga Izinto Eziluhlaza, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lweMpembelelo, Uvavanyo lwe-DWT, Uvavanyo olungonakalisiyo, Uvavanyo loBulukhuni, Uvavanyo loxinzelelo, Uvavanyo lokuvuza kwesihlalo, Uvavanyo lokusebenza kokuhamba kwamanzi, Uvavanyo lweTorque kunye neThrust, Uvavanyo lokupeyinta kunye nokufaka, Uhlolo lwamaxwebhu…..

● Uqhagamshelo

● Ulawulo lwemiyalelo

● Ulawulo lokuhamba komoya

● Ukwahlulwa kweendaba

● Ukuxuba ulwelo

● Inkxaso kunye nokuQinisekisa

● Ulawulo lobushushu

● Ucoceko kunye nokungazalisi

● Ukhuseleko

● Izinto Eziqwalaselwe Ngobuhle Nokusingqongileyo

Ngamafutshane, izixhobo zokufaka iipayipi zizinto ezibalulekileyo ezivumela ukuthuthwa kolwelo kunye neegesi ngokufanelekileyo, ngokukhuselekileyo, nangokulawulwayo kumashishini amaninzi. Usetyenziso lwazo olwahlukeneyo lunegalelo ekuthembekeni, ekusebenzeni, nasekukhuselekeni kweenkqubo zokuphatha ulwelo kwiindawo ezininzi.

Ukupakisha kunye nokuthumela

Apha eWomic Steel, siyaqonda ukubaluleka kokupakishwa okukhuselekileyo kunye nokuthunyelwa okuthembekileyo xa kufikwa ekuziseni izixhobo zethu zombhobho ezikumgangatho ophezulu emnyango wakho. Nantsi ingcaciso emfutshane yeenkqubo zethu zokupakisha kunye nokuthunyelwa ukuze ufumane ireferensi yakho:

Ukupakisha:

Izixhobo zethu zokufaka iipayipi zipakishwe ngononophelo ukuqinisekisa ukuba zifikelela kuwe zikwimeko entle, zilungele iimfuno zakho zoshishino okanye zorhwebo. Inkqubo yethu yokupakisha ibandakanya la manyathelo aphambili alandelayo:

● Ukuhlolwa koMgangatho: Ngaphambi kokuba kupakishwe, zonke izixhobo zombhobho zihlolwa ngononophelo lomgangatho ukuqinisekisa ukuba ziyahlangabezana nemigangatho yethu engqongqo yokusebenza nokuthembeka.

● Ukwaleka Okukhuselekileyo: Ngokuxhomekeke kuhlobo lwezinto kunye nokusetyenziswa kwazo, izixhobo zethu zinokufumana ukwaleka okukhuselekileyo ukuthintela ukugqwala kunye nomonakalo ngexesha lokuthuthwa.

● Ukubopha Okukhuselekileyo: Izinto ezidityanisiweyo zidityaniswe ndawonye ngokukhuselekileyo, ukuqinisekisa ukuba zihlala zizinzile kwaye zikhuselekile kuyo yonke inkqubo yokuthumela.

● Ukubhala iilebheli kunye noXwebhu: Iphakheji nganye ibhalwe ngokucacileyo ngolwazi olubalulekileyo, kubandakanya iinkcukacha zemveliso, ubungakanani, kunye nayo nayiphi na imiyalelo ekhethekileyo yokuphatha. Amaxwebhu afanelekileyo, anjengeziqinisekiso zokuthobela umthetho, nawo afakiwe.

● Ukupakisha Ngokwezifiso: Singakwamkela izicelo zokupakisha ezikhethekileyo ngokusekelwe kwiimfuno zakho ezikhethekileyo, siqinisekisa ukuba izixhobo zakho zilungiselelwe kanye njengoko kufuneka.

Ukuhambisa ngenqanawe:

Sisebenzisana namaqabane ethu okuthumela impahla athembekileyo ukuqinisekisa ukuhanjiswa okuthembekileyo nokufike ngexesha elifanelekileyo kwindawo ochaziweyo. Iqela lethu lezothutho liphucula iindlela zokuthumela impahla ukuze linciphise amaxesha okuthutha impahla kwaye linciphise umngcipheko wokulibaziseka. Kwiimpahla zamanye amazwe, sijongana nazo zonke iimpepha zempahla ezifunekayo kunye nokuthobela imithetho ukuze kube lula ukususwa kwempahla ngendlela ethe tye. Sinikezela ngeendlela zokuthumela impahla eziguquguqukayo, kubandakanya ukuthunyelwa ngokukhawuleza kwiimfuno ezingxamisekileyo.