Ingcaciso yeMveliso

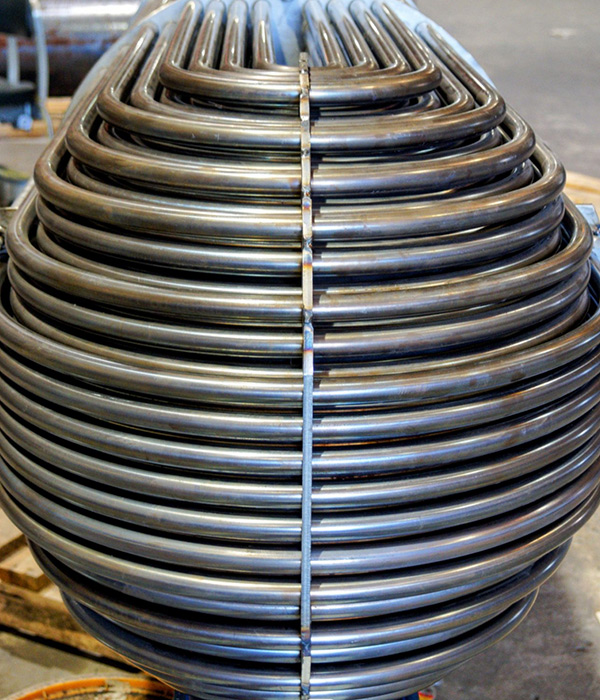

Iinkcukacha zepayipi yebhoyila yentsimbi enobukhulu obupheleleyo (njengobubanzi okanye ubude) kunye nobukhulu bodonga, ipayipi yebhoyila yentsimbi ingasetyenziswa kwipayipi, izixhobo zobuchwepheshe bobushushu, oomatshini bemizi-mveliso, uphando lwejoloji yepetroliyam, izikhongozeli, ishishini leekhemikhali, kunye neminye imisebenzi ekhethekileyo.

Iityhubhu/iipayipi zebhoyila zentsimbi zenziwe ngeepayipi ezingenamthungo, zenziwe ngezinto zentsimbi yekhabhoni okanye ngentsimbi ye-alloy. Iityhubhu/iipayipi zebhoyila zisetyenziswa kakhulu kwiibhoyila zomphunga, kwii-heat exchangers, ekuveliseni amandla, kwizityalo zefosili, kwizityalo zokucubungula izimboni, kwizityalo zombane, kwiifektri zemveliso yeswekile njl. Iityhubhu okanye iipayipi zebhoyila zihlala zisetyenziswa njengebhoyila enoxinzelelo oluphakathi okanye iipayipi zebhoyila ezinoxinzelelo oluphezulu.

Iinkcukacha

| I-ASTM A179 |

| I-ASTM A192 |

| I-ASTM A209: Gr.T1, Gr. T1a, Gr. T1b |

| I-ASTM A210:Gr.A1, Gr.C |

| I-ASTM A106: Gr.A, Gr.B, Gr.C |

| I-DIN 17175: ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| EN 10216-2: P235GH, P265GH, 16Mo3, 10CrMo5-5, 13CrMo4-5 |

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A178:Gr.A, Gr.C |

| I-ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| I-ASTM A333: Ibanga 1, Ibanga 3, Ibanga 4, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9. Ibanga 10, Ibanga 11 |

| I-ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njl.njl.... |

| I-ASTM A269/A269M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njl.njl.... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 |

Imigangatho kunye neBanga

Iityhubhu zeBoiler ezisemgangathweniAmanqanaba:

ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629.

Imeko Yokuhanjiswa: Ifakwe i-Anneal, iqhelekile, ithambile. Umphezulu ufakwe ioyile, upeyintwe ngomnyama, uqhunyiswe nge-shot, ufakwe nge-galvanized eshushu.

| I-ASME SA-179M: | Isitshintshi sobushushu sentsimbi engaphantsi kwekhabhoni kunye neetyhubhu zekhondensi esingenamthungo. |

| I-ASME SA-106: | Umbhobho weNtsimbi yeKhabhoni weNkonzo yoBushushu obuPhezulu. |

| I-ASTM A178: | I-Carbon Steel Welded-Resistance-Equipped kunye ne-Carbon-Manganese Steel Boiler kunye nee-Superheater Tubes. |

| I-ASME SA-192M: | Iityhubhu zeBoiler zeSteel Carbon ezingenamthungo zezixhobo zoxinzelelo oluphezulu. |

| I-ASME SA-210M: | Ibhoyila yentsimbi yekhabhoni ephakathi engenamthungo kunye neetyhubhu zeSuperheater. |

| EN10216-1/2: | Iityhubhu zentsimbi ezingenamthungo ezingasetyenziswanga ngeenjongo zoxinzelelo ezineempawu ezithile zobushushu begumbi. |

| I-JIS G3454: | Imibhobho yentsimbi yekhabhoni yokubonelela ngenkonzo yoxinzelelo kubushushu obuqikelelweyo obuyi-350 degrees Celsius |

| I-JIS G3461: | Iityhubhu zentsimbi yekhabhoni zebhoyila kunye ne-heat exchanger. |

| I-GB 5310: | Iityhubhu zentsimbi ezingenamthungo kunye neepayipi zebhoyila yoxinzelelo oluphezulu. |

| I-ASME SA-335M: | Ibhoyila yentsimbi ye-ferritic ne-austenitic alloy engenamthungo, i-superheater kunye netyhubhu yokutshintshiselana nobushushu. |

| I-ASME SA-213M: | Iityhubhu zentsimbi ye-alloy zeebhoyila, ii-superheaters kunye nezitshintshi zobushushu. |

| I-DIN 17175: | Iityhubhu zentsimbi ezingenamthungo kwiShishini leBoiler, ityhubhu yentsimbi engenamthungo emelana nobushushu, esetyenziselwa imibhobho yeshishini leboiler. |

| I-DIN 1629: | Iibhoyila ezishushu kakhulu, imibhobho yokuvelisa, inqanawa, izixhobo, izixhobo zokufaka iipayipi, kunye nezitshintshi zobushushu ngeepayipi ze-austenitic. |

Ulawulo lwemeko

Ukujonga Izinto Ezingavulwanga, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Uvavanyo loxinzelelo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lwempembelelo, Uvavanyo lwe-DWT, Uvavanyo lwe-NDT, Uvavanyo lwe-Hydrostatic, Uvavanyo loBulukhuni…..

Ukumakisha, Ukupeyinta ngaphambi kokuhanjiswa.

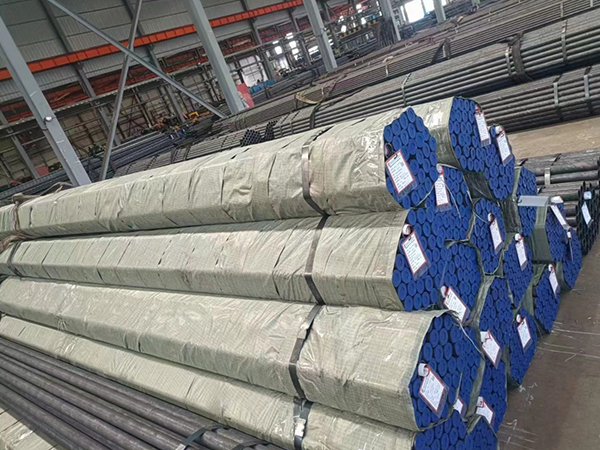

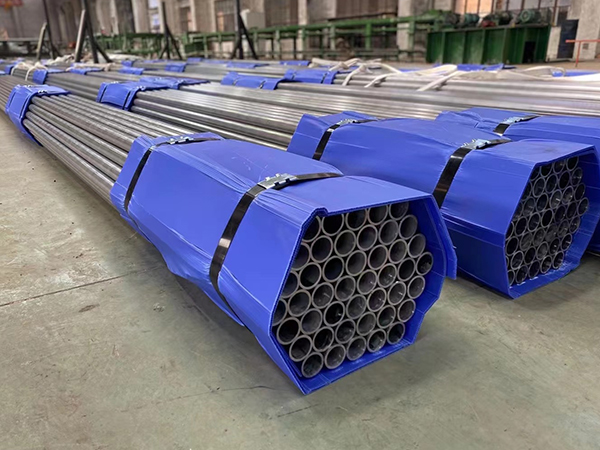

Ukupakisha kunye nokuthumela

Indlela yokupakisha imibhobho yentsimbi ibandakanya ukucoca, ukuhlanganisa, ukusonga, ukubopha, ukubopha, ukulebhelisha, ukufaka iipalethi (ukuba kuyimfuneko), ukufaka kwiikhonteyina, ukuvala, ukuthutha, kunye nokukhupha izinto. Iintlobo ngeentlobo zemibhobho yentsimbi kunye nezixhobo ezineendlela ezahlukeneyo zokupakisha. Le nkqubo ibanzi iqinisekisa ukuba imibhobho yentsimbi ithunyelwa kwaye ifika kwindawo eya kuyo ikwimeko efanelekileyo, ilungele ukusetyenziswa kwayo.

Ukusetyenziswa kunye neSicelo

Iipayipi zentsimbi zisebenza njengomqolo wobunjineli banamhlanje bemizi-mveliso nobokwakha, zixhasa uluhlu olubanzi lwezicelo ezinegalelo kuphuhliso lwentlalo kunye noqoqosho kwihlabathi liphela.

Iipayipi zentsimbi kunye nezixhobo esizivelisileyo zeWomic Steel zisetyenziswa kakhulu kwimibhobho yepetroli, igesi, amafutha kunye namanzi, iiprojekthi zokwakha izibuko lolwandle kunye nokwakha, ukugrumba, iiprojekthi zokwakha intsimbi, ukupakisha kunye neebhulorho, kunye neetyhubhu zentsimbi ezichanekileyo zokuvelisa i-conveyor roller, njl.njl.