Ingcaciso yeMveliso

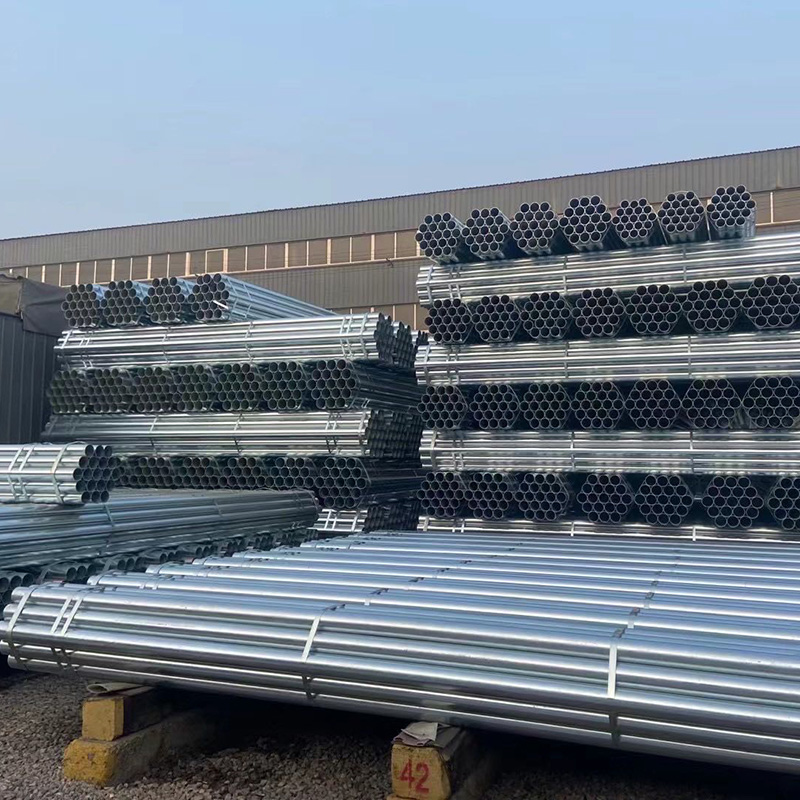

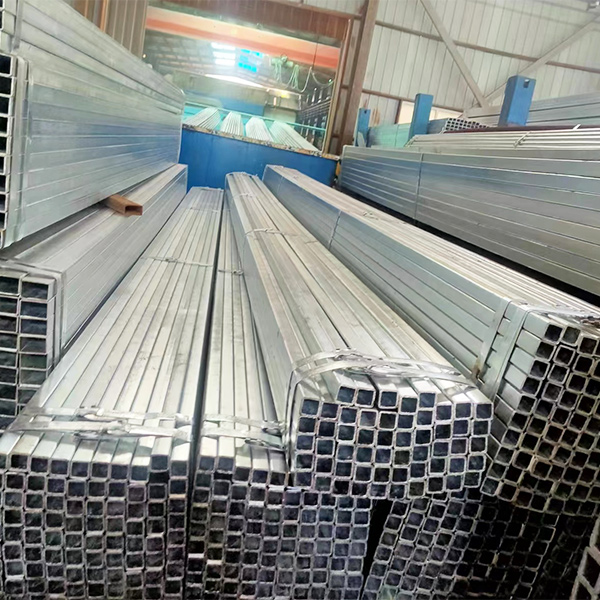

Iipayipi zentsimbi ezigayiweyo ziipayipi zentsimbi eziveliswa kwi-dipped zinc protective coating ukuthintela ukugqwala kunye nokugqwala. Iipayipi zentsimbi ezigayiweyo zingahlulwa zibe yi-hot dip galvanizing pipe kunye ne-pre-galvanizing pipe. Umaleko we-hot-dip galvanizing utyebile, une-plated efanayo, unamathela ngamandla kwaye uhlala ixesha elide.

Iipayipi ze-scaffolding zentsimbi zikwaluhlobo lweepayipi ze-galvanized zi-scaffolding zomsebenzi wangaphakathi nowangaphandle, ezenziwe ngentsimbi yetyhubhu. Iipayipi ze-scaffolding zilula, zinika ukumelana nomoya ophantsi, kwaye iipayipi ze-scaffolding zihlanganiswa kwaye ziqhaqhwe lula. Iipayipi ze-scaffolding ze-galvanized ziyafumaneka ngobude obahlukeneyo kwiindidi ezahlukeneyo zomsebenzi.

Inkqubo ye-scaffolding okanye ii-tubular scaffolds zii-scaffold ezenziwe nge-aluminium galvanized okanye iityhubhu zentsimbi ezidityaniswe kunye yi-coupler exhomekeke ekukhuhlaneni ukuze ixhase umthwalo.

Iingenelo zePipe yeNtsimbi egalelweyo:

Umbhobho wentsimbi ogqunywe nge-galvanized ugcina uluhlu olubanzi lweenzuzo, kwaye usetyenziswa ngokufanelekileyo kwiindawo ezinobungozi kakhulu.

Iingenelo eziphambili zombhobho wesakhiwo ogqunyiweyo ziquka:

- Ikhusela ekungcoleni nasekugqwaleni

- Ukwanda kobude bexesha lokwakha

- Ukuthembeka okuphuculweyo ngokubanzi

- Ukhuseleko olufikelelekayo

- Kulula ukuyihlola

- Ukulungiswa okuncinci

- Ukuqina okuqinileyo

- Kulula ukuyigcina kunemibhobho epeyintiweyo eqhelekileyo

- Ikhuselwe yimigangatho ye-ASTM ephucukileyo

Iipayipi zentsimbi ezigayiweyo Izicelo:

- Umbhobho wentsimbi ogqunyiweyo lukhetho oluhle kakhulu kwiindlela ezininzi zokusetyenziswa kunye neendlela zokucubungula.

Ezinye zezicelo eziqhelekileyo zombhobho wentsimbi egalelweyo ziquka:

- Ukudibanisa iipayipi

- Iiprojekthi zokwakha

- Uthutho lolwelo olushushu nolubandayo

- IiBollards

- Iindawo eziveziweyo ezisetyenzisiweyo iipayipi

- Iipayipi ezisetyenzisiweyo kwiindawo zaselwandle

- Iintsimbi okanye iiHandrails

- Iipali zocingo kunye nocingo

- Umbhobho we-galvanized ungasahwa, utshiswe, okanye udityaniswe ngokhuseleko olufanelekileyo.

Intsimbi Umbhobho wolwakhiwo weGalvanised ungasetyenziselwa iintlobo ngeentlobo zezicelo apho kufuneka ukumelana nokugqwala.

Iinkcukacha

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-BS 1387: Iklasi A, Iklasi B |

| I-ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250, Ibanga C350, Ibanga C450 |

| I-SANS 657-3: 2015 |

Imigangatho kunye neBanga

| BS1387 | I-scaffolding yamasimi okwakha |

| I-API 5L PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | Iipayipi ze-ERW zeoyile yokuthutha, igesi yendalo |

| I-ASTM A53: GR.A, GR.B | Iipayipi zentsimbi ze-ERW zokwakha nokwakha |

| I-ASTM A252 I-ASTM A178 | Iipayipi zentsimbi ze-ERW zeprojekthi zokwakha iipilisi |

| I-AN/NZS 1163 I-AN/NZS 1074 | Iipayipi zentsimbi ze-ERW zeeprojekthi zokwakha izakhiwo |

| EN10219-1 S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Iipayipi ze-ERW ezisetyenziselwa ukuhambisa ulwelo kuxinzelelo oluphantsi/oluphakathi olufana neoyile, igesi, umphunga, amanzi, umoya |

| I-ASTM A500/501, i-ASTM A691 | Iipayipi ze-ERW zokuhambisa ulwelo |

| EN10217-1, S275, S275JR, S355JRH, S355J2H | |

| I-ASTM A672 | Iipayipi ze-ERW zokusetyenziswa koxinzelelo oluphezulu |

| I-ASTM A123/A123M | kwiingubo ze-galvanized ezishushu eziditywayo kwi-stainless steel kunye neemveliso ze-galvanized steel |

| I-ASTM A53/A53M: | Umbhobho wentsimbi omnyama ongenamthungo nowenziwe ngentsimbi eshushu, ogqunywe ngentsimbi emnyama, ogqunywe ngentsimbi eshushu, ogqunywe ngentsimbi, osetyenziswa ngokubanzi. |

| I-EN 10240 | zokugquma zesinyithi, kuquka ukugaya isinyithi, zemibhobho yentsimbi engenamthungo nedibeneyo. |

| EN 10255 | ukuhambisa ulwelo olungengobungozi, kuquka noqweqwe olushushu olufakwe kwi-hot-dip galvanized. |

Ulawulo lwemeko

Ukujonga Izinto Ezingavulwanga, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Uvavanyo loxinzelelo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lwempembelelo, Uvavanyo lwe-DWT, Uvavanyo lwe-NDT, Uvavanyo lwe-Hydrostatic, Uvavanyo loBulukhuni…..

Ukumakisha, Ukupeyinta ngaphambi kokuhanjiswa.

Ukupakisha kunye nokuthumela

Indlela yokupakisha imibhobho yentsimbi ibandakanya ukucoca, ukuhlanganisa, ukusonga, ukubopha, ukubopha, ukulebhelisha, ukufaka iipalethi (ukuba kuyimfuneko), ukufaka kwiikhonteyina, ukuvala, ukuthutha, kunye nokukhupha izinto. Iintlobo ngeentlobo zemibhobho yentsimbi kunye nezixhobo ezineendlela ezahlukeneyo zokupakisha. Le nkqubo ibanzi iqinisekisa ukuba imibhobho yentsimbi ithunyelwa kwaye ifika kwindawo eya kuyo ikwimeko efanelekileyo, ilungele ukusetyenziswa kwayo.

Ukusetyenziswa kunye neSicelo

Umbhobho weGalvanised ngumbhobho wentsimbi oye wagalelwa nge-hot-dip waza wagqunywa ngomaleko we-zinc ukuphucula ukumelana nokugqwala kunye nobomi benkonzo yawo. Umbhobho weGalvanised uneendlela ezahlukeneyo zokusetyenziswa kwiindawo ezahlukeneyo, kuquka kodwa kungaphelelanga apho:

1. Intsimi yokwakha:

Iipayipi ze-galvanized zihlala zisetyenziswa kwizakhiwo zokwakha, ezifana nee-handrails zezitebhisi, ii-railings, iifreyimu zesakhiwo sentsimbi, njl. Ngenxa yokumelana nokugqwala komaleko we-zinc, iipayipi ze-galvanized zingasetyenziswa ngaphandle nakwiindawo ezifumileyo ixesha elide kwaye azinawo umhlwa.

2. Iinkqubo zokubonelela ngamanzi kunye nokukhupha amanzi:

Iipayipi ezigqunyiweyo zisetyenziswa kakhulu kwiinkqubo zokuhambisa amanzi kunye nemibhobho yokuhambisa amanzi ukuze kuthuthwe amanzi okusela, amanzi emizi-mveliso kunye nelindle. Ukumelana kwayo nokugqwala kwenza ukuba ibe lukhetho oluthembekileyo lokunciphisa ukuvaleka kwemibhobho kunye neengxaki zokugqwala.

3. Ukuhanjiswa kweoyile negesi:

Umbhobho we-galvanized usetyenziswa kakhulu kwiinkqubo zemibhobho ezithutha ioyile, igesi yendalo, kunye nezinye izinto ezingamanzi okanye iigesi. Umaleko we-zinc ukhusela imibhobho ekungcoleni nasekungcoleni kwendalo.

4. Iinkqubo ze-HVAC:

Iipayipi ze-galvanized zikwasetyenziswa kwiinkqubo zokufudumeza, zokungenisa umoya kunye nezomoya. Ekubeni ezi nkqubo ziphantsi kweemeko ezahlukeneyo zendalo, ukumelana nokugqwala kwepayipi ye-galvanized kunokwandisa ubomi bayo benkonzo.

5. Iindonga zokukhusela iindlela:

Iipayipi ezigayiweyo zihlala zisetyenziselwa ukwenza iireyili zokukhusela iindlela ukuze ziqinisekise ukhuseleko lwendlela kunye nokuphawula imida yendlela.

6. Icandelo lezeMigodi kunye neShishini:

Kwicandelo lezemigodi nelemizi-mveliso, iipayipi ze-galvanized zisetyenziselwa ukuthutha i-ore, izinto zokwenza izinto, iikhemikhali, njl. Ukumelana kwayo nokugqwala kunye neempawu zayo zokuqina kwenza ukuba ifaneleke ukusetyenziswa kwezi ndawo zinzima.

7. Amasimi ezolimo:

Iipayipi ezifakwe i-galvanized zisetyenziswa kakhulu kwiifama, njengeepayipi zeenkqubo zokunkcenkceshela iifama, ngenxa yokukwazi kwazo ukumelana nokugqwala emhlabeni.

Ngamafutshane, iipayipi ezifakwe i-galvanized zinezicelo ezibalulekileyo kwiindawo ezahlukeneyo, ukusuka kulwakhiwo ukuya kwiziseko zophuhliso ukuya kushishino kunye nezolimo ngenxa yokumelana nokugqwala kunye nokuguquguquka kwazo.

Iipayipi zentsimbi zisebenza njengomqolo wobunjineli banamhlanje bemizi-mveliso nobokwakha, zixhasa uluhlu olubanzi lwezicelo ezinegalelo kuphuhliso lwentlalo kunye noqoqosho kwihlabathi liphela.

Iipayipi zentsimbi kunye nezixhobo esizivelisileyo zeWomic Steel zisetyenziswa kakhulu kwimibhobho yepetroli, igesi, amafutha kunye namanzi, iiprojekthi zokwakha izibuko lolwandle kunye nokwakha, ukugrumba, iiprojekthi zokwakha intsimbi, ukupakisha kunye neebhulorho, kunye neetyhubhu zentsimbi ezichanekileyo zokuvelisa i-conveyor roller, njl.njl.