Ingcaciso yeMveliso

I-WOMIC STEEL ikwanayo nendawo yokusebenzela eyaziwayo yokwenza izinto zokubumba iimveliso zentsimbi yokubumba kunye neemveliso zentsimbi ezibunjiweyo emantla eTshayina. Iimveliso ezininzi zentsimbi yokubumba zinikezelwa kwihlabathi liphela, njengeMexico, eMzantsi-Melika, e-Itali, eYurophu, eMelika, eJapan, eRashiya, eMzantsi-mpuma Asia njalo njalo. Ngobuninzi bamava enkqubo yokwenza intsimbi yokubumba kunye nentsimbi ebunjiweyo, i-WOMIC STEEL ikwaphucula iteknoloji yenkqubo ngokuqhubekayo. Izixhobo ezinkulu zokugaya ibhola, iintlobo ezahlukeneyo zeegiya, ishaft yegiya, i-roller exhasayo, iimbiza ze-slag ezisetyenzisiweyo zokumba ubhedu, oomatshini, iindawo zokubeka iiShovel zombane (izihlangu zomkhondo), iindawo zokutyumza (iiMantles kunye neConcave, iiBowl Liners), kunye nomhlathi oshukumayo oveliswa yiyo zitsale abathengi abaninzi baphesheya ukuba batyelele inkampani. Kwaye zabenza baneliseka ziimveliso zethu.

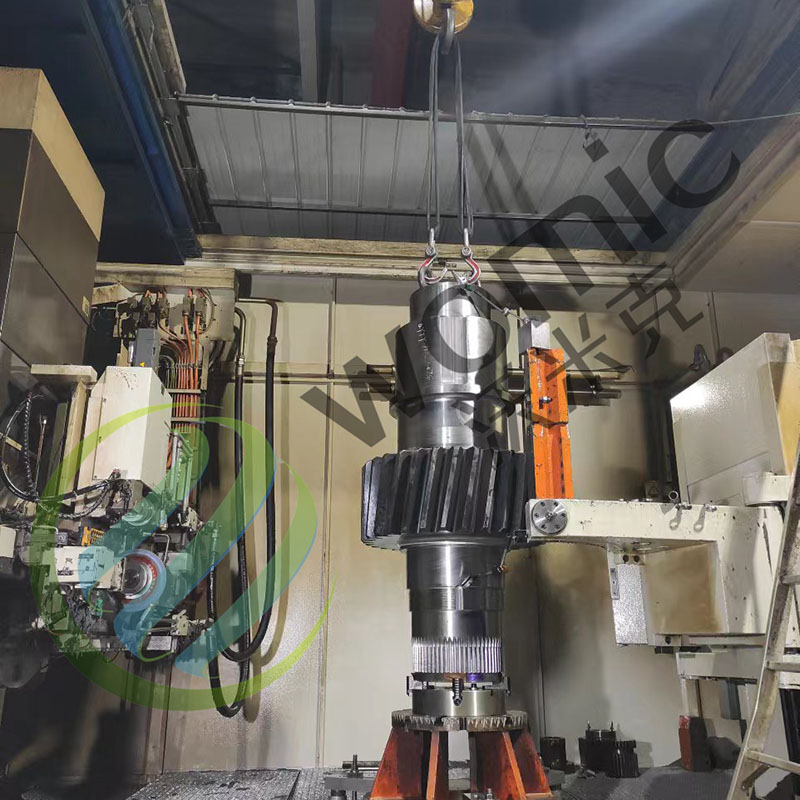

Emva kweminyaka engama-20 yamava okuvelisa nokuthengisa kushishino lokuphosa, ngoku sineqela lobuchwephesha elinamava nelinobuchule, eligxile ekuveliseni ii-castings zentsimbi ezinkulu nezinkulu kakhulu. Inkqubo yemveliso isebenzisa ukuthululwa okudibeneyo, ukuhlelwa kwentsimbi enyibilikisiweyo kube kanye iitoni ezingama-450, kwaye ubunzima obuphezulu bokuphosa bunokufikelela kwiitoni ezingama-300. Ishishini lemveliso libandakanya ukumbiwa kwemigodi, isamente, iinqanawa, ukubumba, isinyithi, ibhulorho, ukugcinwa kwamanzi, Iziko elinye loomatshini (iqela) (oomatshini aba-5 be-TK6920 CNC boring and milling, i-13 CNC 3.15M~8M double column lathe vertical (iqela), i-1 CNC 120x3000 heavy duty plate rolling machine, iiseti ezi-6 zomatshini we-φ1.25m-8m gear hobbing (iqela)) njl.

Izixhobo zokuvelisa kunye nezixhobo zokuvavanya zigqityiwe. Umthamo ophezulu wokuphakamisa imoto enye ziitoni ezingama-300, kunye ne-electric arc furnace enye yeetoni ezingama-30 kunye neetoni ezingama-80, i-double-station LF refinery furnace enye yeetoni ezili-120, umatshini omnye wokuqhumisa i-rotary table shot blasting enye yeetoni ezili-10*10m, ii-electrical heat treatment furnace ezintathu ezishushu kakhulu eziyi-12m*7m*5m, 8m*4m*3.5m, 8m*4m*3.3m, kunye ne-8m*4M*3.3m. Indawo yesihluzo ziimitha ezingama-30,000 zesikwere izixhobo zokususa uthuli lwe-electric arc furnace.

Iziko lovavanyo elizimeleyo lixhotyiswe ngeelebhu yeekhemikhali, i-spectrometer yokufunda ngqo, umatshini wokuvavanya impembelelo, umatshini wokuvavanya ukuxinana, isixhobo sokubona iimpazamo ze-ultrasonic, isivavanyeli sobunzima beLeeb, imakroskopu yesigaba seMetallographic, njl.njl.

Nanini na xa sihlola izinto esizenzayo, siyakwamkela ukuqinisekiswa ukuba izinto ezenziwe ngentsimbi kunye neemveliso ezenziwe ngesinyithi ezenziwe yiWOMIC STEEL zinomgangatho olungileyo kwaye zisebenza ixesha elide, nto leyo enokuhlangabezana neemfuno zoyilo lwabathengi.

Ukuze kusonjululwe imeko yongcoliseko oluphezulu kunye nokusetyenziswa kwamandla aphezulu,

I-WOMIC STEEL isebenzisa izitofu zombane ezisebenza rhoqo kwaye ifake iziqokeleli zothuli kwindawo yokusebenzela. Ngoku, indawo yokusebenza kwindawo yokusebenzela iphuculwe kakhulu. Ngaphambili, i-coke yayitshiswa, kodwa umbane ngoku usetyenziswa, ongagcini nje ngokunciphisa ukusetyenziswa kwamandla, ukonga amandla kunye nokukhusela okusingqongileyo, kodwa uphucula nokuchaneka kwemveliso.

I-WOMIC STEEL iza kuphucula ngakumbi izixhobo zezixhobo zomzi-mveliso, ixhase izixhobo zokwenza izinto ngokuzenzekelayo, ukusetyenziswa kweenkqubo zokwenza izinto ngokuzenzekelayo ukuze kuthathwe iindawo, ukucoca nokupolisha, kunye nokutshiza ngokuzenzekelayo, njl.njl., ukwandisa izinga lokusebenza ngokuzenzekelayo kwenkqubo yemveliso ukuya kuthi ga kwi-90%, kwaye iqhubeke nokuphucula ubuchwepheshe.

Umahluko phakathi kweemveliso zentsimbi eziphoswayo kunye neemveliso zentsimbi eziphosiweyo:

Okokuqala, inkqubo yemveliso yahlukile

Inkqubo yokuvelisa izinto zokugquma kunye neentsimbi zahlukile. Intsimbi egqumayo ibhekisa kuzo zonke iintlobo zezinto ezigqumayo kunye neentsimbi eziveliswa ngendlela yokugquma; Intsimbi egqumayo yintsimbi esetyenziselwa ukugquma. Ukugquma kukuqengqeleka kwezinto eziluhlaza zibe yimo nobukhulu obufunekayo ngempembelelo kunye nokuguqulwa kweplastiki kwezinto zesinyithi. Ngokwahlukileyo koko, izinto ezigqumayo zenziwe ngokugalela isinyithi esinyibilikisiweyo kwimodeli elungiselelwe kwangaphambili, eqina kwaye ipholiswe ukuze kufunyanwe imo nobukhulu obufunekayo. Intsimbi egqumayo idla ngokusetyenziswa ekwenzeni ezinye iindawo ezibalulekileyo zomatshini; Intsimbi egqumayo isetyenziselwa kakhulu ukwenza ezinye iimilo ezintsonkothileyo, ezinzima ukuzigquma okanye ukuzisika kwaye zifuna iindawo ezinamandla aphezulu kunye neplastiki.

Okwesibini, ulwakhiwo lwezinto zahlukile

Ulwakhiwo lwezinto ezisetyenziswa kwi-forgings kunye ne-steel castings nalo lwahlukile. Ii-Forgings zihlala zifana ngakumbi kwaye zinamandla angcono kunye nokumelana nokudinwa. Ngenxa yesakhiwo se-crystalline esixineneyo se-forgings, azikwazi ukuguquguquka kwaye ziqhekeke xa zithwalwa. Ngokwahlukileyo koko, ulwakhiwo lwentsimbi ephosiweyo lukhululekile, nto leyo elula ukuvelisa ukuguquguquka kweplastiki kunye nomonakalo wokudinwa phantsi kwesenzo somthwalo.

Okwesithathu, iimpawu ezahlukeneyo zokusebenza

Iimpawu zokusebenza kwee-forgings kunye nee-castings nazo zahlukile. Ii-Forgings zinokumelana nokugqwala okuphezulu kunye nokubola kwaye zifanelekile kwimithwalo enamandla aphezulu kunye ne-frequency ephezulu. Ngokwahlukileyo koko, ukumelana nokugqwala kunye nokuxhathisa ukugqwala kweendawo zentsimbi ezibunjiweyo ziphantsi kakhulu, kodwa zine-plasticity entle.