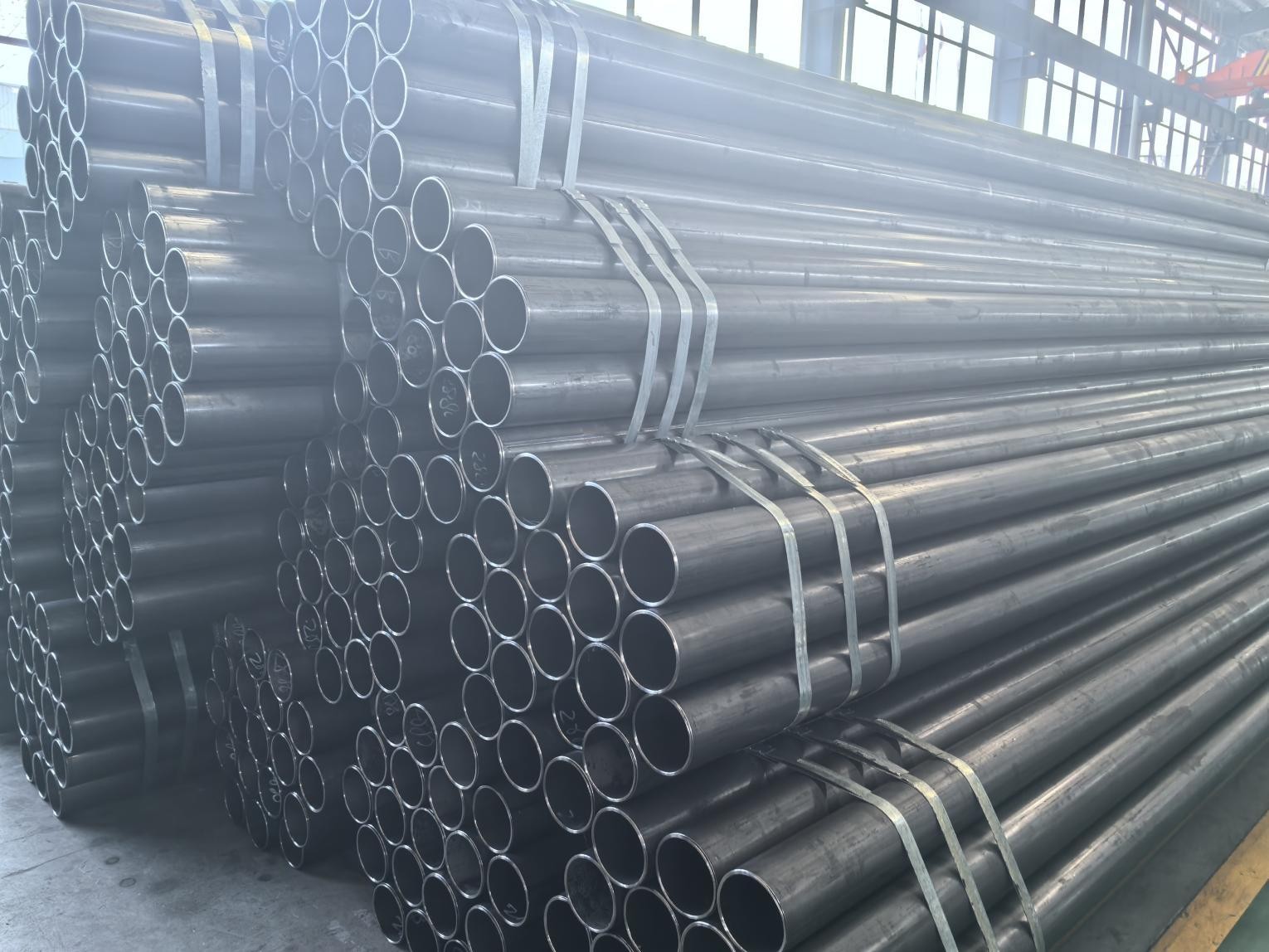

I-Womic Steel igxile ekuveliseni imibhobho yentsimbi esemgangathweni ophezulu ehambelana nemithethoI-DIN 2391imigangatho. Iipayipi zethu zenzelwe ukusetyenziswa ngeendlela ezahlukeneyo, kuquka iinkqubo zothutho lwesakhiwo, oomatshini, kunye nolwelo. Sisebenzisa iteknoloji yokuvelisa ephucukileyo kunye neenkqubo zokulawula umgangatho ezingqongqo, siqinisekisa ukuba iimveliso zethu ziyahlangabezana nemigangatho yamazwe ngamazwe, zibonelela ngokuqina, ukuchaneka, kunye nokusebenza okungenakuthelekiswa nanto.

Iipayipi zethu zentsimbi zilungele ngokukodwa ukusetyenziswa kwii-idlers, ii-hydraulic kunye nee-pneumatic cylinders, ubunjineli boomatshini kunye neemoto, oomatshini, iityhubhu ze-oyile cylinder, iityhubhu zentsimbi ze-motorcycle shock absorber, kunye nee-auto shock absorber zangaphakathi. Ezi zicelo zifuna iipayipi ezinamandla aphezulu, ezenziwe ngobuchule obuchanekileyo ezinikezela ukuthembeka nokusebenza okugqwesileyo kwiindawo ezifuna amandla.

I-DIN 2391 Iityhubhu Zokuchaneka Ezingenamthungo Uluhlu lweMveliso:

- Ububanzi obungaphandle (OD): 6 mm ukuya kwi-400 mm

- Ubukhulu bodonga (WT): 1 mm ukuya kwi-18 mm

- Ubude: Ubude obulungiselelwe wena bufumaneka, buhlala buqala kwiimitha ezi-6 ukuya kwezili-12, kuxhomekeke kwiimfuno zeprojekthi.

I-DIN 2391 Iityhubhu Zokuchaneka Ezingenamthungo Ukunyamezelana:

| Ipharamitha | Ukunyamezelana |

| Ububanzi obungaphandle (OD) | ± 0.01mm |

| Ubukhulu bodonga (WT) | ± 0.1 mm yobukhulu bodonga obuchaziweyo |

| Ukuqanda (Ukuqanda) | 0.1 mm |

| Ubude | ± 5 mm |

| Ukuthe tye | Ubuninzi yi-1 mm ngemitha nganye |

| Umphezulu wokugqiba | Ngokweenkcazo zomthengi (Ngokwesiqhelo: Ioyile echasene nomhlwa, i-hard chrome plating, i-nickel chromium plating, okanye enye i-Coating) |

| Isikwere seziphelo | ± 1° |

I-DIN 2391 Iityhubhu Zokuchaneka Ezingenamthungo Ukwenziwa kweeKhemikhali

| Umgangatho | Ibanga | Iinxalenye zeekhemikhali (%) | |||||

| Isimboli | Inombolo yezinto ezisetyenzisiweyo | C | Si | Mn | P | S | |

| I-DIN2391 | ISt 30 Si | 1.0211 | ≤0.10 | ≤0.30 | ≤0.55 | ≤0.025 | ≤0.025 |

| ISt 30 Al | 1.0212 | ≤0.10 | ≤0.05 | ≤0.55 | ≤0.025 | ≤0.025 | |

| ISt 35 | 1.0308 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| ISt 5 | 1.0408 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| ISt 52 | 1.058 | ≤0.22 | ≤0.55 | ≤1.60 | ≤0.025 | ≤0.025 | |

Ezi zinto zilandelayo zokudibanisa zingongezwa: Nb: ≤ 0,03 %; Ti: ≤ 0,03 %; V: ≤ 0,05 %; Nb + Ti + V: ≤ 0,05 %

I-DIN 2391 Iityhubhu Zokuchaneka Ezingenamthungo Iimeko zokuhanjiswa

Iityhubhu maziveliswe ngeenkqubo ezitsalwa ngokubandayo okanye ezisongiweyo ngokubandayo. Iityhubhu mazibonelelwe ngenye yeemeko zokuhanjiswa ngolu hlobo lulandelayo:

| Ukutyunjwa | Isimboli | Inkcazo |

| Igqityiwe kubanda (iqinile) | BK | Iityhubhu azinyangwa ngobushushu emva kokubanda kokugqibela, ngoko ke, zinokumelana nokuguquguquka okuphezulu. |

| Igqityiwe kubanda (ithambile) | BKW | Unyango lokugqibela lobushushu lulandelwa kukutsalwa okubandayo okubandakanya ukuguquguquka okuncinci. Ukulungiswa okufanelekileyo kuvumela inqanaba elithile lokwakheka kobanda (umz. ukugoba, ukwanda). |

| Igqityiwe kubanda kwaye ithomalalisiwe kuxinzelelo | I-BKS | Unyango lobushushu lusetyenziswa emva kwenkqubo yokugqibela yokwenza umkhuhlane. Ngokuxhomekeke kwiimeko ezifanelekileyo zokucubungula, ukwanda koxinzelelo olushiyekileyo olubandakanyekayo kwenza ukuba ukwenziwa kunye nokufakelwa kube kwinqanaba elithile. |

| I-Annealed | GBK | Inkqubo yokugqibela yokwenza umkhuhlane ilandelwa kukutsalwa kwe-annealing kwindawo elawulwayo. |

| Iqhelekile | I-NBK | Inkqubo yokugqibela yokwenza umkhuhlane ilandelwa kukutsalwa ngaphezulu kwendawo yokuguqula ephezulu kwindawo elawulwayo. |

I-DIN 2391 Iityhubhu Zokuchaneka Ezingenamthungo Iipropati zoomatshini.

| Iipropati zoomatshini kubushushu begumbi | |||||||||||||

| Ibanga lentsimbi | Amaxabiso aphantsi kwimeko yokuhanjiswa | ||||||||||||

| Igama lentsimbi | Inombolo yentsimbi | BK | BKW | I-BKS | GBK | I-NBK | |||||||

| Rm | Ipesenti ye-A | Rm | Ipesenti ye-A | Rm | I-ReH | Ipesenti ye-A | Rm | Ipesenti ye-A | Rm | I-ReH | Ipesenti ye-A | ||

| I-Mpa | I-Mpa | I-Mpa | I-Mpa | I-Mpa | I-Mpa | I-Mpa | |||||||

| ISt 30 Si | 1.0211 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 ukuya ku-420 | 215 | 30 |

| ISt 30 Al | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 ukuya ku-420 | 215 | 30 |

| ISt 35 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 315 | 14 | 315 | 25 | 340 ukuya ku-470 | 235 | 25 |

| ISt 45 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440 ukuya ku-570 | 255 | 21 |

| ISt 52 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 420 | 10 | 490 | 22 | 490 ukuya ku-630 | 355 | 22 |

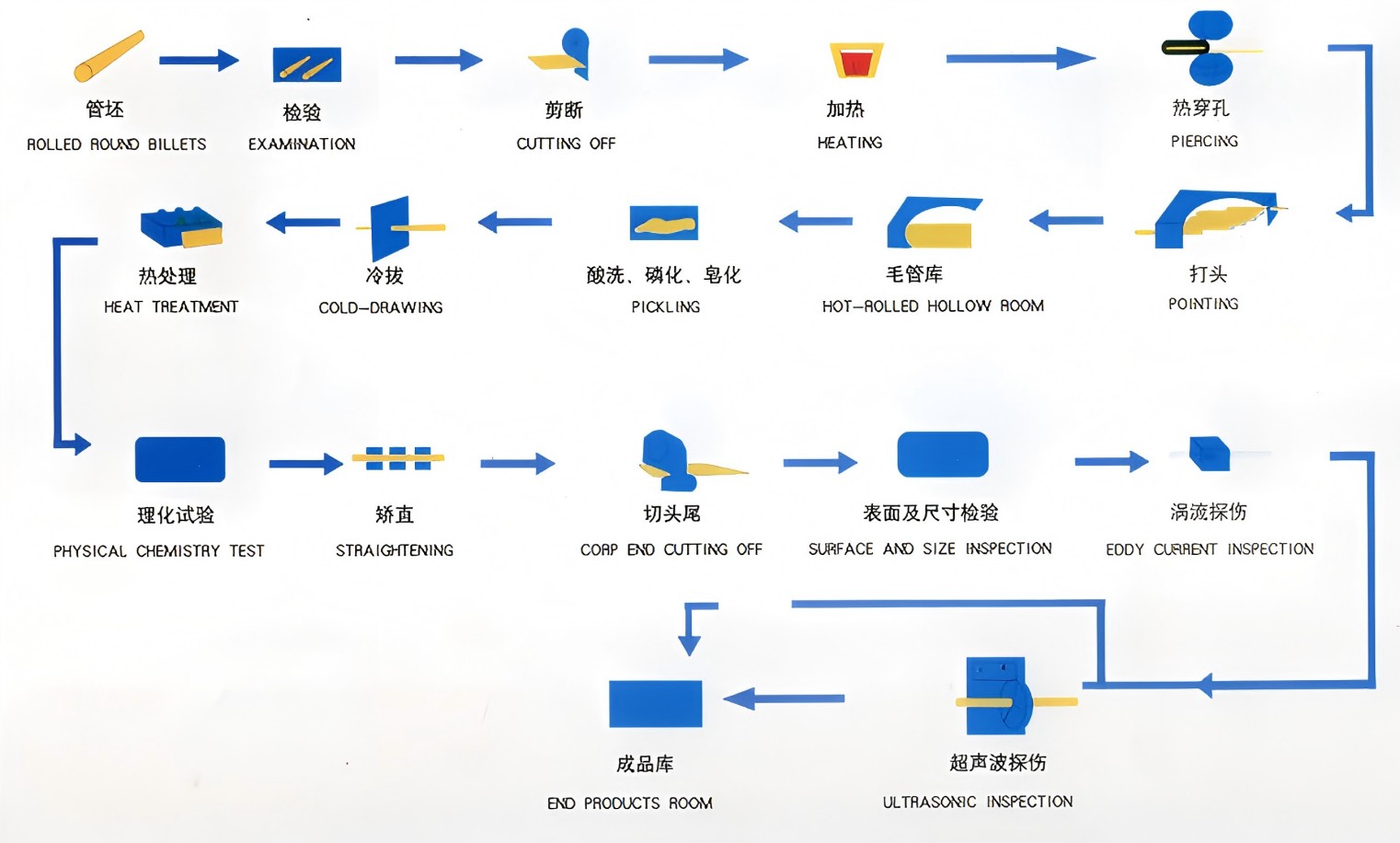

I-DIN 2391 Iityhubhu Zokuchaneka Ezingenamthungo Inkqubo yoMveliso:

- ·Iibhilethi ezijikelezileyo: Imveliso iqala ngokusetyenziswa kweebhilethi ezijikelezileyo, ezizizinto zokuqala eziluhlaza ngendlela yeentonga zentsimbi.

- ·Uvavanyo: Ezi billets zihlolwa kuqala ngomgangatho kunye nokuhambelana ukuqinisekisa ukuba ziyahlangabezana nemigangatho efunekayo ngaphambi kokuba ziqhubekele kwinqanaba elilandelayo.

- ·Ukusika: Emva koko iibhilethi ziyanqunyulwa zibe nobude obufunekayo ukuze zihambelane neemfuno zokuqhubekeka nokusebenza.

- ·Ukufudumeza: Iibhilethi ezisikiweyo zitshiswa kubushushu obuphezulu ukuze zilungele ukuguquguquka ngakumbi kumanyathelo alandelayo.

- ·Ukubhoboza: Emva koko iibhilethi ezishushu ziyagqojozwa ukuze kwenziwe iziko elingenanto, elenza isakhiwo esisisiseko sombhobho ongenamthungo.

- ·Igumbi Elingenanto Eligoqwe Ngobushushu: Iibhilethi ezingenanto zijijelwa ngobushushu ukuze zibumbe umbhobho ngakumbi.

- ·Itsalwe Ngobandayo: Iipayipi eziqengqelekayo ezishushu emva koko zitsalwa ngedayi phantsi kweemeko ezilawulwayo, zinciphisa ububanzi kunye nobukhulu, kwaye zicocise ubukhulu bombhobho.

- ·Ukukha: Iipayipi zifakwa kwisisombululo se-asidi ukususa naluphi na ulusu lomphezulu okanye ukungcola okwenziwe ngexesha lenkqubo yokwenziwa.

- ·Unyango lobushushu: Le mibhobho inyangwa ngobushushu, nto leyo equka iinkqubo ezifana nokutsalwa kwe-annealing ukuphucula iimpawu zayo zoomatshini kunye nokunciphisa uxinzelelo.

- ·Uvavanyo lweKhemistri yoMzimba: Iipayipi zivavanyelwa ngokwasemzimbeni nangokweekhemikhali ukuqinisekisa ukuba ziyahlangabezana neemfuno zezinto kunye neempawu ezifunekayo.

- ·Ukulungisa: Emva konyango lobushushu, imibhobho iyalungiswa ukuqinisekisa ukuba iyafana kwaye ichanekile.

- ·Ukusika Isiphelo Sekhoyili: Iziphelo zemibhobho zinqunqwe ngobude obufunekayo.

- ·Ukuhlolwa komphezulu kunye nobungakanani: Iipayipi zihlolwa kakuhle ukuze zibone iziphene zomphezulu kwaye zihlolwe ukuba zichanekile na ubukhulu ukuqinisekisa umgangatho.

- ·Uhlolo lwangoku lwe-EddyOlu vavanyo olungonakalisiyo lusetyenziselwa ukubona naziphi na iintanda okanye iziphene ezingabonakaliyo emehlweni.

- ·Uvavanyo lwe-Ultrasonic: Iipayipi ziyavavanywa nge-ultrasound ukuze kufunyanwe naziphi na iziphene zangaphakathi okanye iziphene ezinokuchaphazela amandla okanye ukuthembeka kombhobho.

- ·Igumbi leMveliso yokuphela: Ekugqibeleni, imibhobho egqityiweyo ithunyelwa kwigumbi lemveliso yokugqibela, apho ipakishwa khona kwaye ilungiselelwe ukuthunyelwa.

Uvavanyo kunye nokuhlolwa:

I-Womic Steel iqinisekisa ukulandeleka ngokupheleleyo kunye nokuqinisekiswa komgangatho wee-allDIN 2391 Seamless Precision Tubes ngokusebenzisa ezi vavanyo zilandelayo:

- Uvavanyo lweMilinganiselo: Ukulinganiswa kwe-OD, i-WT, ubude, i-ovality, kunye nokuthe tye.

- Uvavanyo lweMishini:

- Uvavanyo lokuThatha

- Uvavanyo lweMpembelelo

- Uvavanyo loBulukhuni

- Uvavanyo Olungonakalisiyo (NDT):Uhlalutyo lweeKhemikhali: Kwenziwe ukuqinisekisa ukwakheka kwezinto kusetyenziswa iindlela ze-spectrographic.

- Uvavanyo lwangoku lwe-Eddy lweziphene zangaphakathi

- Uvavanyo lwe-Ultrasonic (UT) lobukhulu bodonga kunye nokuthembeka kwalo

- Uvavanyo lwe-Hydrostatic: Ukujonga ukuba umbhobho uyakwazi na ukumelana noxinzelelo lwangaphakathi ngaphandle kokusilela.

Ulawulo lweLebhu kunye noMgangatho:

I-Womic Steel isebenzisa ilebhu exhotyiswe ngokupheleleyo enezixhobo zovavanyo nokuhlola eziphambili ukuqinisekisa ukuthotyelwa kwemigangatho ye-DIN 2391 Seamless Precision Tubes. Iingcali zethu zobugcisa zenza uhlolo lomgangatho rhoqo ngaphakathi kwibhetshi nganye yeepayipi. Sikwasebenzisana ngokusondeleyo neearhente ezizimeleyo zangaphandle ukuqinisekisa umgangatho weepayipi ngaphandle.

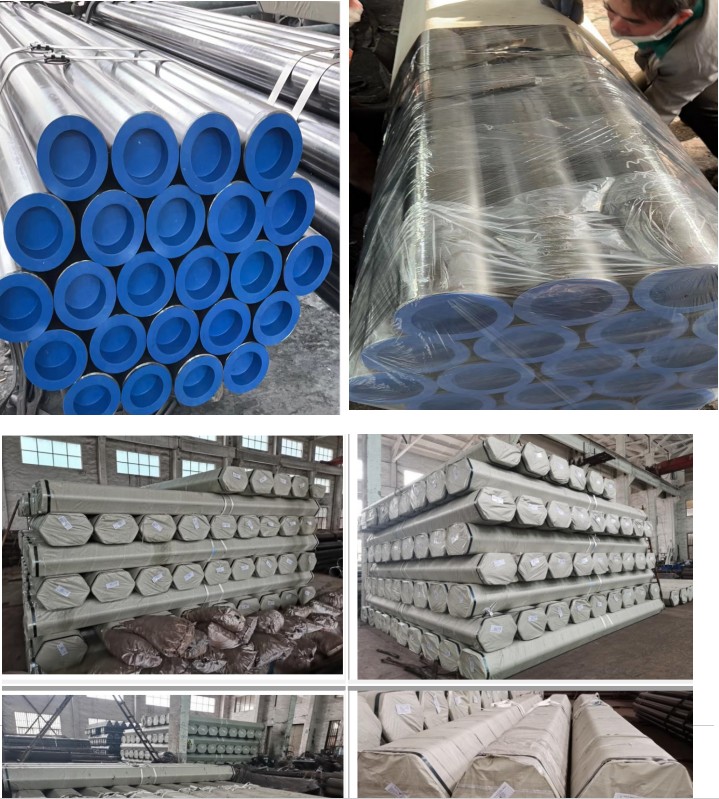

Ukupakisha

Ukwaleka okuKhuselekileyo: Ityhubhu nganye icocwa kwaye igqunywe ngomaleko ochasene nokugqwala ukuthintela ukugqwala okanye ukugqwala ngexesha lokuthuthwa nokugcinwa. Oku kungabandakanya umaleko weoyile, iwax, okanye ezinye izinto zokukhusela ngokweemfuno zabathengi.

Ii-Caps zokuphela: Zombini iziphelo zeetyhubhu zivalwe ngeplastiki okanye ngesinyithi ukuthintela ukungcola, ukufuma, kunye nomonakalo ngexesha lokuphathwa nokuthuthwa.

Ukuhlanganisa: Ezi tyhubhu zihlanganiswa zibe ziipakeji ezilawulekayo, ngesiqhelo zibe nobude obuhambelana neemfuno zokuthunyelwa ezisemgangathweni. Iibhakeji zisongwa ngeebhakethi zentsimbi, iibhanti zeplastiki, okanye iibhanti ezilukiweyo ukuze zibambeke kakuhle.

Ukhuseleko phakathi kweetyhubhu: Ukuze kuthintelwe ukudibana ngqo nokuthintela ukukrwela okanye ukonakala, iityhubhu ezingaphakathi kwezi mfumba zihlala zahlulwe ngezinto zokukhusela ezifana nekhadibhodi, izithuba zomthi, okanye izinto zokufaka igwebu.

Izinto zokuPakisha: Iimfumba zeetyhubhu zihlala zisongelwa nge-shrink wrap okanye ifilimu yeplastiki enzima ukuqinisekisa ukuba zihlala ziqinile ngexesha lokuthuthwa kwaye zikhuselekile eluthulini nakumswakama.

Ukuchongwa kunye nokuLebhelishwa: Iphakheji nganye iphawulwe ngokucacileyo ngeenkcukacha zemveliso, kubandakanya umgangatho wentsimbi, ubukhulu (ububanzi, ubukhulu, ubude), ubungakanani, inombolo yebhetshi, kunye nezinye iinkcukacha ezifanelekileyo. Iileyibhile zinokubandakanya imiyalelo yokuphatha efana nokuthi "Gcina Umile" okanye "Phatha Ngononophelo."

Uthutho

Indlela yoThutho:

Ukuthutha Ulwandle: Kwiimpahla ezithunyelwa kwamanye amazwe, iityhubhu ezichanekileyo ezingenamthungo zihlala zithunyelwa ngolwandle. Iibhakethi zilayishwa kwiikhonteyina zokuthumela okanye kwiirakhi ezithe tyaba, kuxhomekeke kubukhulu nobude beetyhubhu.

Uthutho lweSitimela okanye lweNdlela: Kwimithwalo yasekhaya okanye yengingqi, iityhubhu zinokuthuthwa ngololiwe okanye ngendlela, zilayishwe kwiilori ezisicaba okanye kwiikhonteyina.

Ukulayisha nokukhusela: Xa zilayishwa kwizithuthi zothutho, iibhanti zibotshelelwa ngokukhuselekileyo ukuthintela ukushukuma okanye ukuhamba ngexesha lokuhamba. Oku kunokufezekiswa kusetyenziswa imitya yentsimbi, iibhanti zeplastiki, kunye nokuxhaswa okongeziweyo ngaphakathi kwisikhongozeli okanye kwilori. Kwimithwalo yolwandle, ukuba iityhubhu azikho kwisikhongozeli, zihlala zilayishwa kwiirakhi ezithe tyaba kwaye ziqiniswe ngeetarps ezongezelelweyo okanye izigqubuthelo ukuze zikhuseleke kwiimeko zemozulu ezifana nemvula okanye ukuvezwa kwamanzi anetyuwa.

Ulawulo lweMozulu: Ukuba kuyimfuneko (ingakumbi kwimimandla efumileyo okanye eselunxwemeni), iimeko zothutho ezilawulwayo (umz., ulawulo lobushushu kunye nokufuma) zinokucwangciswa ukuthintela nawuphi na umonakalo ovela kwizinto ezingqongileyo ngexesha lokuhamba.

Amaxwebhu: Amaxwebhu okuhambisa afanelekileyo ayalungiselelwa ukuze kugqitywe irhafu yempahla kunye nokulandelwa kwezothutho, kubandakanya ne-bill of lading, isatifikethi semvelaphi, izatifikethi zomgangatho, kunye namanye amaxwebhu ayimfuneko olawulo.

I-inshurensi: Ukukhusela kumonakalo, ilahleko, okanye ubusela obunokubakho ngexesha lokuhamba, kuyacetyiswa ukuba kulungiselelwe umshuwalense wokuthunyelwa, ingakumbi ukuthunyelwa kwamanye amazwe.

Iingenelo zokukhetha intsimbi yeWomic:

- Ukuvelisa ngokuchanekileyoIinkqubo zethu zemveliso zanamhlanje zisivumela ukuba sihlangabezane nobunzima obungqongqo bokubekezelela ububanzi, ubukhulu bodonga, kunye nokuma.

- Izixhobo ezikumgangatho ophezulu: Sifumana kuphela intsimbi ekumgangatho ophezulu kubaboneleli abathembekileyo, siqinisekisa iipropati ezibalaseleyo zoomatshini kunye nokumelana nokugqwala.

- Ukwenziwa ngokwezifiso: Sinikezela ngezisombululo ezenzelwe wena ngokusekelwe kwiimfuno zabathengi, kubandakanya ubude obuthile, unyango lomphezulu, kunye neendlela zokupakisha.

- Uvavanyo olupheleleyo: Ngeenkqubo zethu zokuvavanya ezingqongqo, siqinisekisa ukuba umbhobho ngamnye uyahlangabezana nazo zonke iimfuno zobugcisa kunye nemithetho, unikezela ngokusebenza okuthembekileyo nokuqina.

- Iqela elinamavaIqela lethu leenjineli kunye neengcali zinobuchule obuphezulu nolwazi, ziqinisekisa imigangatho ephezulu kwimveliso nakwinkonzo yabathengi.

- Ukuhanjiswa Ngexesha: Sisebenza nenethiwekhi ye-logistics ethembekileyo, siqinisekisa ukuhanjiswa kwezinto ngexesha elifanelekileyo kuyo nayiphi na indawo yehlabathi.

Isiphelo:

Iityhubhu zeWomic Steel zeDIN 2391 Seamless Precision ziyafana nokusebenza okuphezulu, ukuqina, kunye nokuveliswa ngokuchanekileyo. Ukuzibophelela kwethu kumgangatho kunye nokwaneliseka kwabathengi kusenza sahluke njengeenkokheli kwimveliso yeepayipi zentsimbi. Nokuba zezokwakha, oomatshini, okanye iinkqubo zolwelo, iimveliso zethu zenzelwe ukuhlangabezana nemigangatho ephezulu yokuthembeka kunye namandla.

Khetha iWomic Steel Group njengeqabane lakho elithembekileyo leeMbhobho zeNtsimbi engagqwaliyo kunye nokufakelwa kwayo okusemgangathweni kunye nokusebenza kakuhle kokuhambisa. Wamkelekile Umbuzo!

Iwebhusayithi: www.womicsteel.com

I-imeyile: sales@womicsteel.com

Ucingo/WhatsApp/WeChat: Victor: +86-15575100681 okanye uJack: +86-18390957568