Ingcaciso yeMveliso

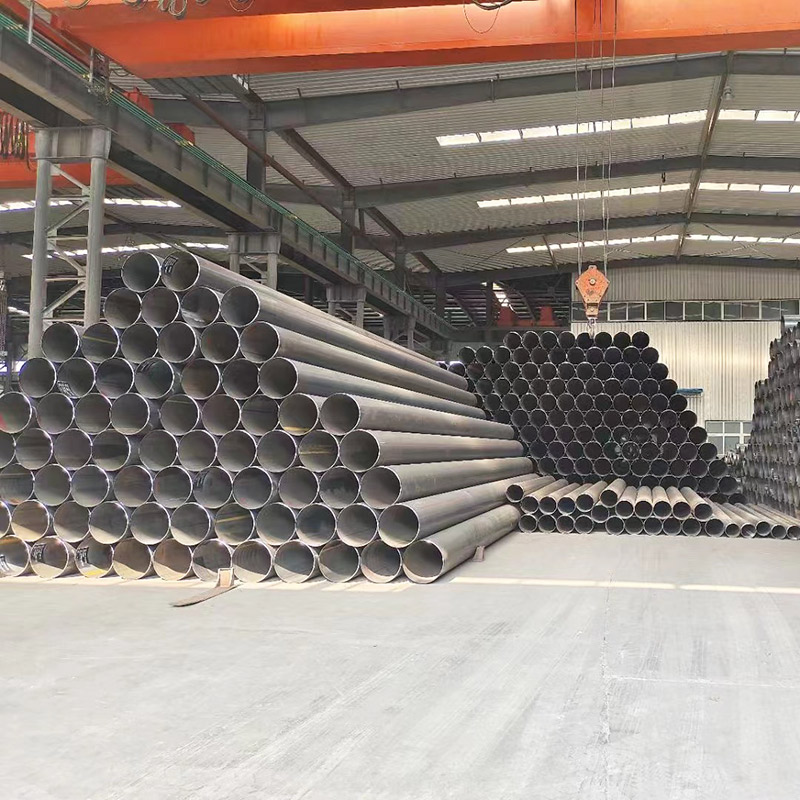

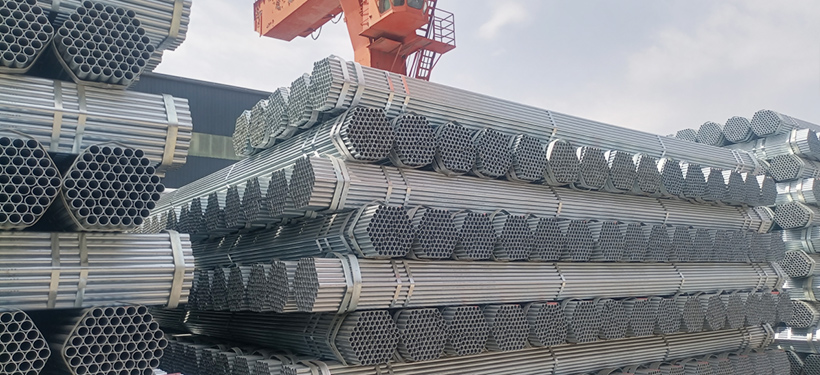

Ukuwelda kokumelana nombane, iiMbhobho zentsimbi ze-ERW zenziwe ngokwenza i-coil yentsimbi ebandayo ibe yimilo engqukuva. IiMbhobho ze-ERW zenziwe ngombane we-AC ophantsi ukuze kufudunyezwe imiphetho ekuqaleni. Ngoku i-AC ephindaphindayo ephezulu endaweni yombane wenkqubo ye-frequency ephantsi ukuze kuvelise i-weld esemgangathweni ophezulu.

Iipayipi zentsimbi ze-ERW zenziwe ngombane ophantsi okanye oxhathisayo oluphezulu. Iipayipi zentsimbi ze-ERW ziityhubhu ezingqukuva ezidityanisiweyo kwiipleyiti zentsimbi ezinee-welds ezinde. Zisetyenziselwa ukuthutha igesi kunye nezinto ezingamanzi ezifana neoyile kunye negesi yendalo, kwaye zinokuhlangabezana neemfuno ezahlukeneyo zoxinzelelo oluphezulu noluphantsi.

Iipayipi zentsimbi ze-ERW zisetyenziswa kakhulu ekubiyeni, kwiipayipi zomgca, kwi-scaffolding njl.njl.

Imibhobho yentsimbi ye-ERW iveliswa ngobubanzi obahlukeneyo, ubukhulu bodonga, ukugqitywa kunye namanqanaba.

Izicelo eziphambili

● Iipayipi ze-ERW ezisetyenziswa kwiipayipi zamanzi

● Ezolimo kunye nokunkcenkceshela (Iindlela eziphambili zamanzi, imibhobho yamanzi yemizi-mveliso, imibhobho yezityalo, iipayipi ezinzulu kunye nemibhobho yokubeka, imibhobho yokuhambisa amanzi amdaka)

● Iintambo zepayipi zegesi

● I-LPG kunye neminye imigca yegesi engenabungozi

Iinkcukacha

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-BS 1387: Iklasi A, Iklasi B |

| I-ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250, Ibanga C350, Ibanga C450 |

| I-SANS 657-3: 2015 |

Imigangatho kunye neBanga

| I-API 5L PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | Iipayipi ze-ERW zeoyile yokuthutha, igesi yendalo |

| I-ASTM A53: GR.A, GR.B | Iipayipi zentsimbi ze-ERW zokwakha nokwakha |

| I-ASTM A252 I-ASTM A178 | Iipayipi zentsimbi ze-ERW zeprojekthi zokwakha iipilisi |

| I-AN/NZS 1163 I-AN/NZS 1074 | Iipayipi zentsimbi ze-ERW zeeprojekthi zokwakha izakhiwo |

| EN10219-1 S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Iipayipi ze-ERW ezisetyenziselwa ukuhambisa ulwelo kuxinzelelo oluphantsi/oluphakathi olufana neoyile, igesi, umphunga, amanzi, umoya |

| I-ASTM A500/501, i-ASTM A691 | Iipayipi ze-ERW zokuhambisa ulwelo |

| EN10217-1, S275, S275JR, S355JRH, S355J2H | |

| I-ASTM A672 | Iipayipi ze-ERW zokusetyenziswa koxinzelelo oluphezulu |

Ulawulo lwemeko

Ukujonga Izinto Ezingavulwanga, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Uvavanyo loxinzelelo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lwempembelelo, Uvavanyo lwe-DWT, Uvavanyo lwe-NDT, Uvavanyo lwe-Hydrostatic, Uvavanyo loBulukhuni…..

Ukumakisha, Ukupeyinta ngaphambi kokuhanjiswa.

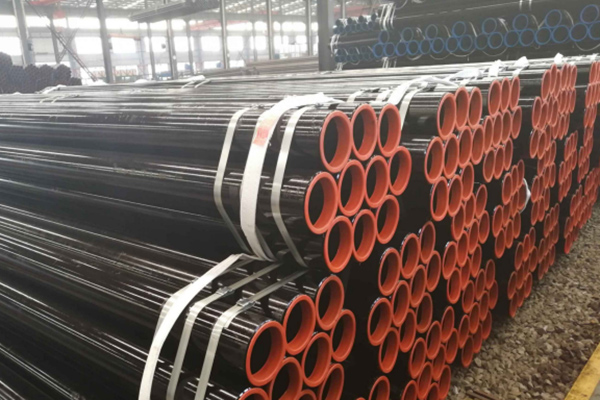

Ukupakisha kunye nokuthumela

Indlela yokupakisha imibhobho yentsimbi ibandakanya ukucoca, ukuhlanganisa, ukusonga, ukubopha, ukubopha, ukulebhelisha, ukufaka iipalethi (ukuba kuyimfuneko), ukufaka kwiikhonteyina, ukuvala, ukuthutha, kunye nokukhupha izinto. Iintlobo ngeentlobo zemibhobho yentsimbi kunye nezixhobo ezineendlela ezahlukeneyo zokupakisha. Le nkqubo ibanzi iqinisekisa ukuba imibhobho yentsimbi ithunyelwa kwaye ifika kwindawo eya kuyo ikwimeko efanelekileyo, ilungele ukusetyenziswa kwayo.

Ukusetyenziswa kunye neSicelo

Iipayipi zentsimbi zisebenza njengomqolo wobunjineli banamhlanje bemizi-mveliso nobokwakha, zixhasa uluhlu olubanzi lwezicelo ezinegalelo kuphuhliso lwentlalo kunye noqoqosho kwihlabathi liphela.

Iipayipi zentsimbi kunye nezixhobo esizivelisileyo zeWomic Steel zisetyenziswa kakhulu kwimibhobho yepetroli, igesi, amafutha kunye namanzi, iiprojekthi zokwakha izibuko lolwandle kunye nokwakha, ukugrumba, iiprojekthi zokwakha intsimbi, ukupakisha kunye neebhulorho, kunye neetyhubhu zentsimbi ezichanekileyo zokuvelisa i-conveyor roller, njl.njl.