Ingcaciso yeMveliso

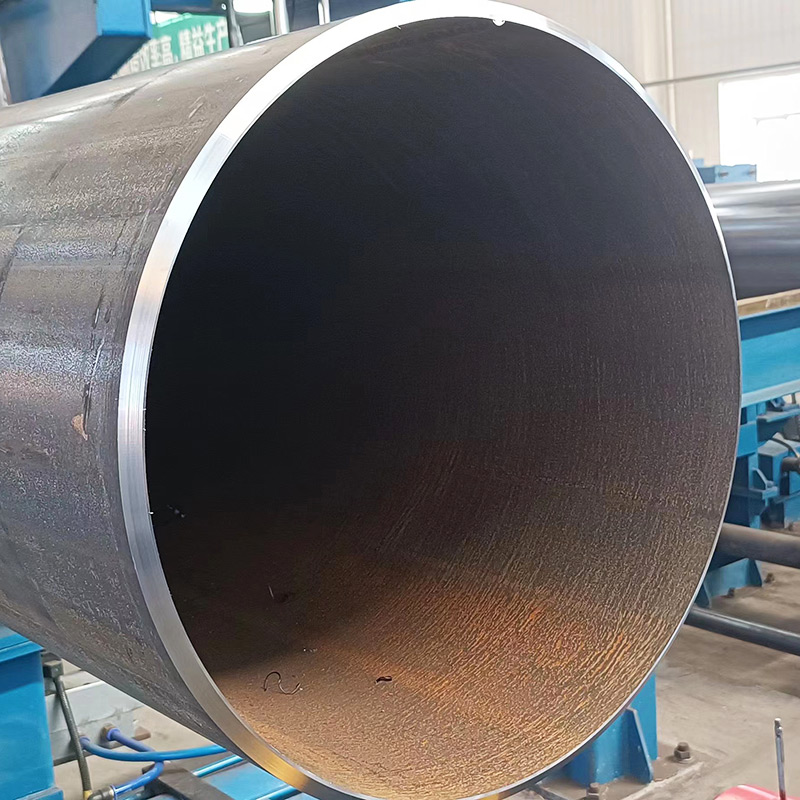

Iipayipi zentsimbi ze-LSAW (Longitudinal Submerged Arc Welding) luhlobo lombhobho wentsimbi odibeneyo ophawulwa yinkqubo yawo yokuvelisa eyahlukileyo kunye noluhlu olubanzi lwezicelo. Ezi payipi zenziwe ngokwenza ipleyiti yentsimbi ibe yimo ye-cylindrical kwaye idityaniswe ngobude kusetyenziswa iindlela zokudityanisa i-arc engaphantsi komhlaba. Nantsi ingcaciso ngokubanzi yeepayipi zentsimbi ze-LSAW:

Inkqubo yoMveliso:

● Ukulungiswa kwePlate: Iipleyiti zentsimbi ezikumgangatho ophezulu zikhethwa ngokusekelwe kwiimfuno ezithile, ukuqinisekisa iipropati zoomatshini ezifunekayo kunye nokwakheka kweekhemikhali.

● Ukwakheka: Ipleyiti yentsimbi ibunjwe ibe yipayipi esisilinda ngokusebenzisa iinkqubo ezifana nokugoba, ukuqengqeleka, okanye ukucinezela (i-JCOE kunye ne-UOE). Imiphetho igobile kwangaphambili ukuze kube lula ukuwelda.

● Ukuwelda: Kusetyenziswa ukuwelda kwe-arc engaphantsi komhlaba (SAW), apho i-arc igcinwa phantsi komaleko we-flux. Oku kuvelisa ukuwelda okusemgangathweni ophezulu okuneempazamo ezincinci kunye nokudibanisa okuhle kakhulu.

● Ukuhlolwa kwe-Ultrasonic: Emva kokuwelda, uvavanyo lwe-ultrasound lwenziwa ukuze kufunyanwe naziphi na iziphene zangaphakathi okanye zangaphandle kwindawo yokuwelda.

● Ukwandisa: Umbhobho ungandiswa ukuze kufikelelwe kububanzi obufunekayo kunye nobukhulu bodonga, nto leyo ephucula ukuchaneka kobukhulu.

● Uhlolo lokugqibela: Uvavanyo olupheleleyo, oluquka ukuhlolwa okubonakalayo, ukujonga ubungakanani, kunye novavanyo lweempawu zoomatshini, luqinisekisa umgangatho wombhobho.

Iingenelo:

● Ukonga iindleko: Iipayipi ze-LSAW zibonelela ngesisombululo esingabizi kakhulu kwiipayipi ezinkulu kunye nokusetyenziswa kwezakhiwo ngenxa yenkqubo yazo yokuvelisa esebenza kakuhle.

● Amandla Aphezulu: Indlela yokuwelda ende iphumela kwiipayipi ezineempawu zoomatshini eziqinileyo nezifanayo.

● Ukuchaneka kobukhulu: Iipayipi ze-LSAW zibonisa ubukhulu obuchanekileyo, nto leyo eyenza zifaneleke ukusetyenziswa ngokunyamezela okungqongqo.

● Umgangatho weWeld: Ukuwelda kwe-arc engaphantsi komhlaba kuvelisa ukuwelda okusemgangathweni ophezulu okune-fusion entle kakhulu kunye neziphene ezincinci.

● Ukuguquguquka: Iipayipi ze-LSAW zisetyenziswa kumashishini ahlukeneyo, kuquka ioyile negesi, ulwakhiwo, kunye nokunikezelwa kwamanzi, ngenxa yokuba ziyakwazi ukuzivumelanisa nezimo kwaye zihlala ixesha elide.

Ngamafutshane, iipayipi zentsimbi ze-LSAW zenziwa kusetyenziswa inkqubo echanekileyo nesebenzayo, nto leyo ebangela ukuba kubekho iipayipi eziguquguqukayo, ezingabizi kakhulu, nezihlala ixesha elide ezifanelekileyo kwiintlobo ngeentlobo zezicelo zoshishino.

Iinkcukacha

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250, Ibanga C350, Ibanga C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| I-ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

Uluhlu lweMveliso

| Ububanzi obungaphandle | Ubukhulu bodonga obufumanekayo ngaphantsi kwenqanaba lentsimbi | |||||||

| Intshi | mm | Ibanga lentsimbi | ||||||

| Intshi | mm | L245(Gr.B) | L290(X42) | L360(X52) | L415(X60) | L450(X65) | L485(X70) | L555(X80) |

| 16 | 406 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 18 | 457 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 20 | 508 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 22 | 559 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 24 | 610 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 26 | 660 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 28 | 711 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 30 | 762 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 32 | 813 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 34 | 864 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 36 | 914 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 38 | 965 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 40 | 1016 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 42 | 1067 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 44 | 1118 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 46 | 1168 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 48 | 1219 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 52 | 1321 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 56 | 1422 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 60 | 1524 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 64 | 1626 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 68 | 1727 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 72 | 1829 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

* Ezinye iisayizi zingenziwa ngokwezifiso emva kwengxoxo

Ukwakhiwa kweeKhemikhali kunye neeMpawu zoMatshini zePipe yeNtsimbi ye-LSAW

| Umgangatho | Ibanga | Ulwakhiwo lweekhemikhali (ubuninzi)% | Iipropati zoomatshini (umzuzu) | |||||

| C | Mn | Si | S | P | Amandla emveliso (i-Mpa) | Amandla okuThamba (i-Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| I-BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| I-DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| I-JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| I-API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Imigangatho kunye neBanga

| Umgangatho | Amanqanaba eNsimbi |

| I-API 5L: Inkcazo yePipe yoMgca | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: Inkcazo esemgangathweni yeePile zeMbhobho zeNsimbi eziWelded nezingenamthungo | GR.1, GR.2, GR.3 |

| I-EN 10219-1: Amacandelo angaphakathi adibeneyo afakwe kwisakhiwo esibandayo seentsimbi ezingezizo i-alloy kunye neentsimbi ezincinci | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: Amacandelo ashushu agqityiweyo olwakhiwo olungenanto yokuxuba kunye neentsimbi zengqolowa ezintle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: Ipayipi, Intsimbi, Imnyama kwaye Itshisiwe, Igqunywe ngeZinc, Idityanisiwe kwaye Ayinamthungo | GR.A, GR.B |

| EN10208: Iipayipi zentsimbi ezisetyenziswa kwiinkqubo zothutho lweepayipi kwimizi-mveliso yepetroliyam negesi yendalo. | L210GA, L235GA, L245GA, L290GA, L360GA |

| EN 10217: Iityhubhu zentsimbi ezidityanisiweyo ngeenjongo zoxinzelelo | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-DIN 2458: Iipayipi zentsimbi edibeneyo kunye neetyhubhu | I-St37.0, I-St44.0, I-St52.0 |

| I-AS/NZS 1163: Umgangatho wase-Australia/waseNew Zealand weeCandelo zeNsimbi eziMgobo ezenziwe ngeNsimbi | Ibanga C250 , Ibanga C350 , Ibanga C450 |

| GB/T 9711: Amashishini ePetroleum neGesi yendalo - Umbhobho weNtsimbi weeMibhobho | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| I-ASTM A671: Umbhobho wentsimbi odibeneyo ngombane ukuze kusetyenziswe amaqondo obushushu aphantsi naphakathi komoya | I-CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70 |

| I-ASTM A672: Umbhobho wentsimbi odityaniswe ngombane odityaniswe ngombane ukuze kusetyenziswe uxinzelelo oluphezulu kumaqondo obushushu aphakathi. | A45, A50, A55, B60, B65, B70, C55, C60, C65 |

| I-ASTM A691: Umbhobho wesinyithi wekhabhoni kunye ne-alloy, odityaniswe ngombane ukuze usetyenziswe xa kushushu kakhulu. | I-CM-65, I-CM-70, I-CM-75, I-1/2CR-1/2MO, I-1CR-1/2MO, I-2-1/4CR, 3CR |

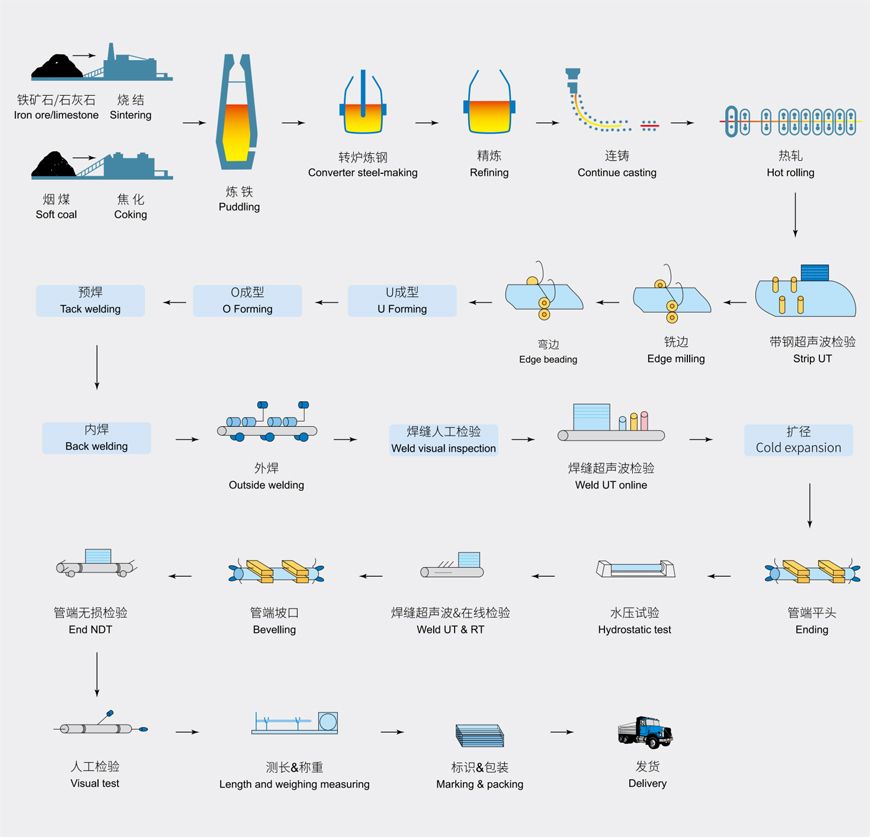

Inkqubo yoMveliso

Ulawulo lwemeko

● Ukujonga Izinto Ezingasetyenzwanga

● Uhlalutyo lweeKhemikhali

● Uvavanyo lweMishini

● Ukuhlolwa koMbono

● Ukujonga Ubungakanani

● Uvavanyo lokugoba

● Uvavanyo lweMpembelelo

● Uvavanyo lokuGqobhoka phakathi kweegranular

● Uvavanyo Olungonakalisiyo (UT, MT, PT)

● Isiqinisekiso seNkqubo yokuWelda

● Uhlalutyo lweMicrstructure

● Uvavanyo lokuGqiba nokuQoqa

● Uvavanyo loBulukhuni

● Uvavanyo lwe-Hydrostatic

● Uvavanyo lweMetallography

● Uvavanyo lokuqhekeka olubangelwa yiHydrogen (HIC)

● Uvavanyo lokuqhekeka koxinzelelo lwe-sulfide (SSC)

● Uvavanyo lwangoku luka-Eddy

● Ukuhlolwa kokupeyinta kunye nokugquma

● Uhlolo lwamaxwebhu

Ukusetyenziswa kunye neSicelo

Iipayipi zentsimbi ze-LSAW (Longitudinal Submerged Arc Welding) zisetyenziswa ngeendlela ezahlukeneyo kumashishini ahlukeneyo ngenxa yobuchule bazo bokwakha kunye nokuguquguquka kwazo. Nazi ezinye zeendlela eziphambili zokusetyenziswa kunye nokusetyenziswa kweepayipi zentsimbi ze-LSAW:

● Uthutho lweoyile negesi: Iipayipi zentsimbi ze-LSAW zisetyenziswa kakhulu kushishino lweoyile negesi kwiinkqubo zemibhobho. Ezi pipes zisetyenziselwa ukuthutha ioyile eluhlaza, igesi yendalo, kunye nezinye izinto eziphuma kulwelo okanye iigesi.

● Iziseko Zophuhliso Lwamanzi: Imibhobho ye-LSAW isetyenziswa kwiiprojekthi zeziseko zophuhliso ezinxulumene namanzi, kuquka ukunikezelwa kwamanzi kunye neenkqubo zokuhambisa amanzi.

● Ukucubungula iikhemikhali: Iipayipi ze-LSAW zisebenza kumashishini eekhemikhali apho zisetyenziselwa ukuhambisa iikhemikhali, ulwelo kunye neegesi ngendlela ekhuselekileyo nefanelekileyo.

● Ulwakhiwo kunye neZiseko zoPhuhliso: Le mibhobho isetyenziswa kwiiprojekthi ezahlukeneyo zokwakha, ezifana neziseko zokwakha, iibhulorho, kunye nezinye izinto ezisetyenziswayo kwizakhiwo.

● Ukufaka iipayipi: Iipayipi ze-LSAW zisetyenziswa kwizicelo zokufaka iipayipi ukubonelela ngenkxaso yesiseko kwiiprojekthi zokwakha, kuquka iziseko zokwakha kunye nezakhiwo zaselwandle.

● Icandelo laMandla: Zisetyenziselwa ukuthutha iintlobo ezahlukeneyo zamandla, kuquka umphunga kunye nolwelo olushushu kwizityalo zokuvelisa umbane.

● Ukwemba: Imibhobho ye-LSAW isetyenziswa kwiiprojekthi zezemigodi zokuhambisa izinto kunye neentsalela.

● Iinkqubo zemizi-mveliso: Amashishini afana nokuvelisa nokuvelisa asebenzisa iipayipi ze-LSAW kwiinkqubo ezahlukeneyo zoshishino, kuquka ukuhambisa izinto ezikrwada kunye neemveliso ezigqityiweyo.

● Uphuhliso lweZiseko zoPhuhliso: Ezi mbhobho zibalulekile ekuphuhliseni iiprojekthi zeziseko zophuhliso ezifana neendlela, iindlela ezinkulu, kunye neenkonzo ezingaphantsi komhlaba.

● Inkxaso yoLwakhiwo: Iipayipi ze-LSAW zisetyenziselwa ukwenza izixhaso zolwakhiwo, iikholamu, kunye neebhili kwiprojekthi zokwakha nezobunjineli.

● Ukwakha iinqanawa: Kwishishini lokwakha iinqanawa, iipayipi ze-LSAW zisetyenziselwa ukwakha iindawo ezahlukeneyo zeenqanawa, kuquka iinqanawa kunye nezinto zokwakha.

● Ishishini leeMoto: Iipayipi ze-LSAW zingasetyenziswa ekwenzeni izinto zeemoto, kuquka neenkqubo zokukhupha umoya.

Ezi zicelo zibonisa ukuguquguquka kwemibhobho yentsimbi ye-LSAW kumacandelo ahlukeneyo, ngenxa yokuqina kwayo, amandla ayo, kunye nokufaneleka kwayo kwiimeko ezahlukeneyo zokusingqongileyo.

Ukupakisha kunye nokuthumela

Ukupakishwa ngokufanelekileyo kunye nokuthunyelwa kwemibhobho yentsimbi ye-LSAW (Longitudinal Submerged Arc Welding) kubalulekile ukuqinisekisa ukuthuthwa kwayo ngokukhuselekileyo kunye nokuhanjiswa kwayo kwiindawo ezahlukeneyo. Nantsi inkcazo yeenkqubo eziqhelekileyo zokupakisha kunye nokuthunyelwa kwemibhobho yentsimbi ye-LSAW:

Ukupakisha:

● Ukubopha: Iipayipi ze-LSAW zihlala zihlanganiswa okanye zipakishwe ngeSingle Piece kusetyenziswa imitya yentsimbi okanye iibhendi ukwenza iiyunithi ezilawulekayo zokuphatha nezokuthutha.

● Ukhuseleko: Iziphelo zemibhobho zikhuselwe ngemivalo yeplastiki ukuthintela umonakalo ngexesha lokuhamba. Ukongeza, imibhobho inokugqunywa ngezinto zokukhusela ukukhusela kwiimeko zokusingqongileyo.

● Ukwaleka Okuchasene Nokugqwala: Ukuba imibhobho inekwaleka okuchasene nokugqwala, ukuthembeka kokwaleka kuyaqinisekiswa ngexesha lokupakisha ukuthintela umonakalo ngexesha lokuphathwa nokuthuthwa.

● Ukuphawula kunye nokuLebhelisha: Iphakheji nganye ineelebheli ezineenkcukacha ezibalulekileyo ezifana nobukhulu bombhobho, umgangatho wezinto, inombolo yobushushu, kunye nezinye iinkcukacha ukuze kube lula ukuyiqonda.

● Ukubopha: Iibhanti zibotshelelwa ngokuqinileyo kwiipalethi okanye kwiiskidi ukuthintela intshukumo ngexesha lokuthuthwa.

Ukuhambisa ngenqanawe:

● Iindlela Zothutho: Iipayipi zentsimbi ze-LSAW zingathunyelwa kusetyenziswa iindlela ezahlukeneyo zothutho, kuquka indlela, uloliwe, ulwandle, okanye umoya, kuxhomekeke kwindawo oya kuyo kunye nongxamiseko.

● Ukufakwa kwiikhonteyina: Iipayipi zingathunyelwa kwiikhonteyina ukuze zikhuseleke ngakumbi, ingakumbi xa kuthuthwa phesheya kolwandle. Iikhonteyina ziyalayishwa kwaye ziqiniswe ukuze zingashukumi ngexesha lokuthuthwa.

● Amaqabane eLogistics: Iinkampani okanye abathwali bempahla abaziwayo abanamava okuphatha imibhobho yentsimbi bayabandakanyeka ukuqinisekisa ukuhanjiswa kwayo ngokukhuselekileyo nangokufanelekileyo.

● Amaxwebhu eerhafu: Amaxwebhu ayimfuneko eerhafu, kuquka amaphepha okuthumela impahla, izatifikethi zemvelaphi, kunye namanye amaphepha afanelekileyo, ayalungiswa aze angeniswe ukuze athunyelwe kwamanye amazwe.

● I-inshorensi: Ngokuxhomekeke kwixabiso kunye nohlobo lomthwalo, i-inshorensi inokulungiselelwa ukukhusela kwiziganeko ezingalindelekanga ngexesha lokuhamba.

● Ukulandelela: Iinkqubo zokulandelela zanamhlanje zivumela umthumeli kunye nomamkeli ukuba balandelele inkqubela yokuthunyelwa ngexesha langempela, ukuqinisekisa ukuba akukho nto ifihlakeleyo kwaye uhlaziyo lufike ngexesha elifanelekileyo.

● Ukuhanjiswa: Imibhobho ikhutshwa kwindawo eya kuyo, kulandela iinkqubo ezifanelekileyo zokukhupha impahla ukuze kuthintelwe umonakalo.

● Ukuhlolwa: Xa ifika, imibhobho inokuhlolwa ukuqinisekisa imeko yayo kunye nokuhambelana kwayo nemimiselo ngaphambi kokuba yamkelwe ngumntu oza kuyifumana.

Iindlela ezifanelekileyo zokupakisha nokuthumela impahla zinceda ekuthinteleni umonakalo, zigcine ukuthembeka kwemibhobho yentsimbi ye-LSAW, kwaye ziqinisekise ukuba ifika kwindawo ezicetywayo ngokukhuselekileyo kwaye ikwimeko efanelekileyo.