Iipayipi ngokwendlela ezisetyenziswa ngayo kunye nezixhobo zepayipi, iindlela zoqhagamshelo ezisetyenziswa rhoqo zezi: uqhagamshelo olunemisonto, uqhagamshelo lweflange, ukuwelda, uqhagamshelo lwegroove (uqhagamshelo lwe-clamp), uqhagamshelo lwe-ferrule, uqhagamshelo loxinzelelo lwekhadi, uqhagamshelo olushushu olunyibilikayo, uqhagamshelo lwesokethi njalo njalo.

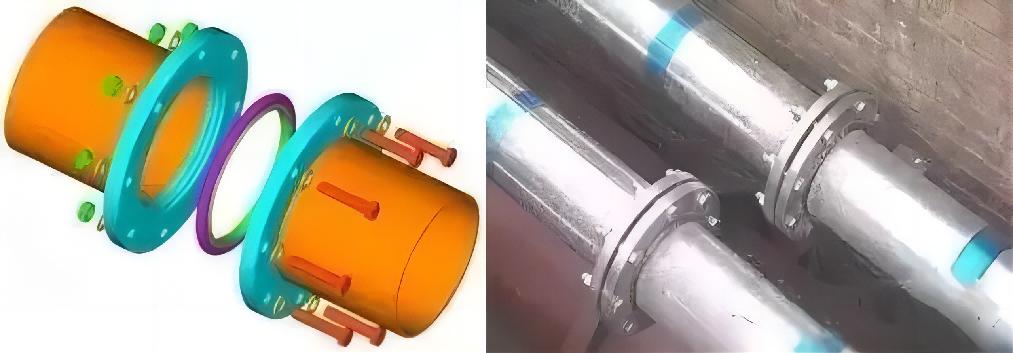

1. Uqhagamshelo lweFlange

Iipayipi ezinkulu ezinobubanzi ziqhagamshelwe ngeeflanges, kwaye uqhagamshelo lweflange lusetyenziswa ngokubanzi kwiivalvu eziphambili zoqhagamshelo, iivalvu zokujonga, iimitha zamanzi, iimpompo, njl.njl., kunye nesidingo sokuqhaqha rhoqo kunye nokugcinwa kwecandelo lepayipi. Iipayipi zegalaji ezifana nokuwelda okanye uqhagamshelo lweflange, ukuwelda kufuneka kube yigalange yesibini okanye ukugqwala.

2. Ukuwelda

Ukuwelda kusebenza kumbhobho wentsimbi ongagqunywanga nge-galvanized, osetyenziswa kakhulu kwiipayipi ezifihliweyo kunye neepayipi ezinkulu ezinobubanzi, kunye nokusetyenziswa okungakumbi kwizakhiwo eziphakamileyo. Uqhagamshelo lombhobho wethusi lungasebenzisa iijoyinti ezikhethekileyo okanye ukuwelda, xa ububanzi bombhobho bungaphantsi kwe-22mm socket okanye ukuwelda kwe-casing kufanelekile, isokhethi kufuneka ihlangabezane nofakelo lwe-media flow direction, xa ububanzi bombhobho bukhulu kune-22mm okanye bulingana ne-XNUMXmm kufanelekile ukusebenzisa ukuwelda kwe-butt. Umbhobho wentsimbi engagqwaliyo unokuba kukuwelda kwe-socket.

3. Uqhagamshelo lweSikrufu

Uqhagamshelo olunemisonto lusetyenziswa kukufakelwa kwemibhobho enoqhagamshelo olunemisonto, ububanzi bombhobho obungaphantsi okanye obulingana ne-100mm yombhobho wentsimbi egayiweyo kufuneka buqhagamshelo olunemisonto, olusetyenziswa kakhulu kumbhobho ovulekileyo. Umbhobho odibeneyo wentsimbi-iplastiki ngokubanzi usetyenziswa kuqhagamshelo olunemisonto. Umbhobho wentsimbi egayiweyo kufuneka ube noqhagamshelo olunemisonto, iseti yebhakede yesilika xa kutshatyalaliswa umphezulu womaleko ogayiweyo kunye nenxalenye eveziweyo eneemisonto kufuneka yenziwe ukuthintela ukugqwala; kufuneka isetyenziswe kwiifayinti ezikhethekileyo zohlobo lweflange okanye lwe-ferrule ukudibanisa umbhobho wentsimbi egayiweyo kwaye iflange ye-weld kufuneka iqatywe okwesibini.

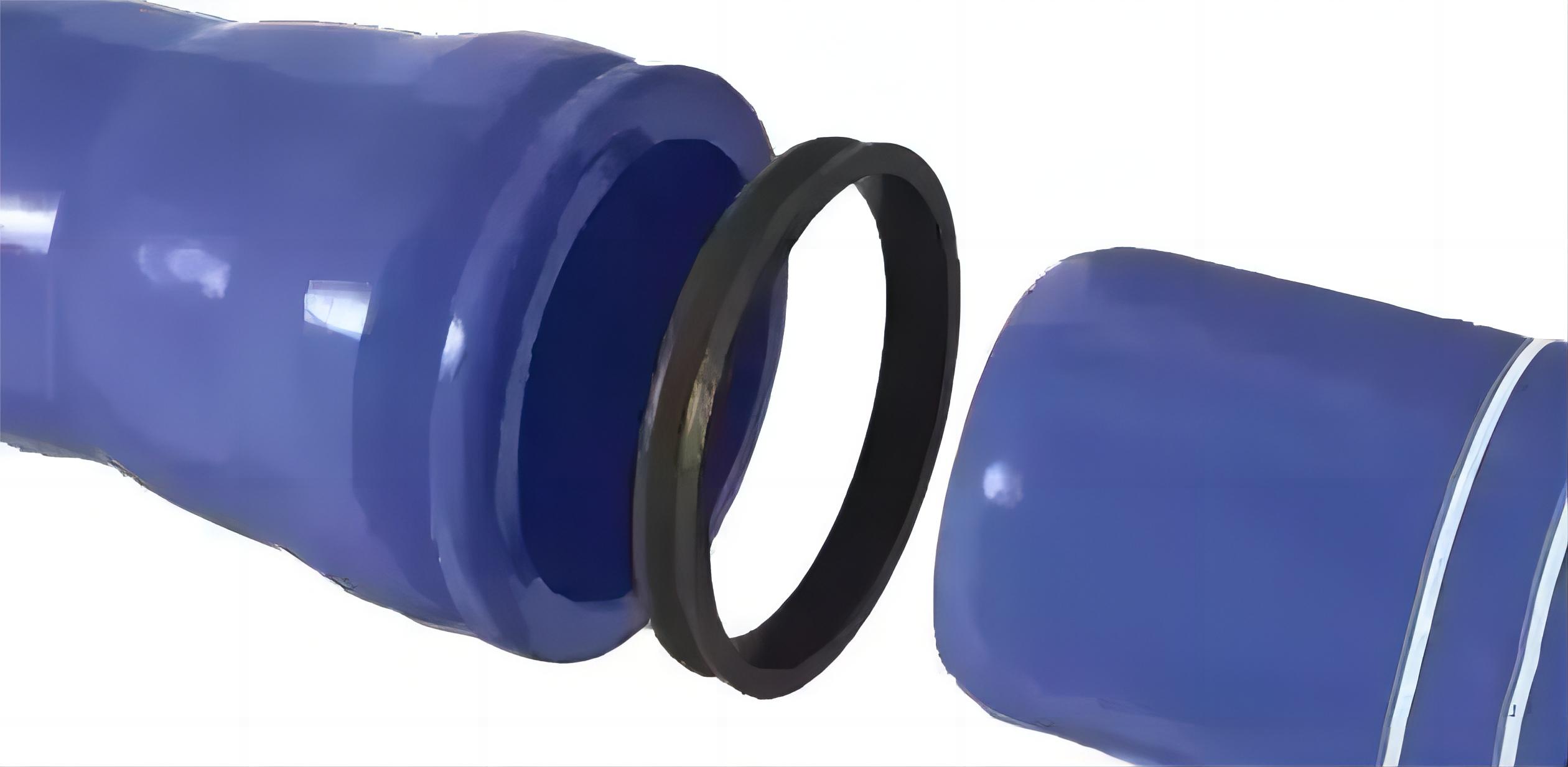

4. Uqhagamshelo lweSocket

Isetyenziselwa ukuhanjiswa kwamanzi kunye nokudibanisa imibhobho yesinyithi esityhidiweyo kunye nezixhobo zombhobho. Kukho iintlobo ezimbini zokudibanisa okuguquguqukayo kunye nokudibanisa okuqinileyo, ukunxibelelana okuguquguqukayo kutywinwa ngeeringi zerabha, ukunxibelelana okuqinileyo kutywinwa ngesamente ye-asbestos okanye izizalisi ezinkulu, kwaye izitywini ze-lead ziyafumaneka kwiziganeko ezibalulekileyo.

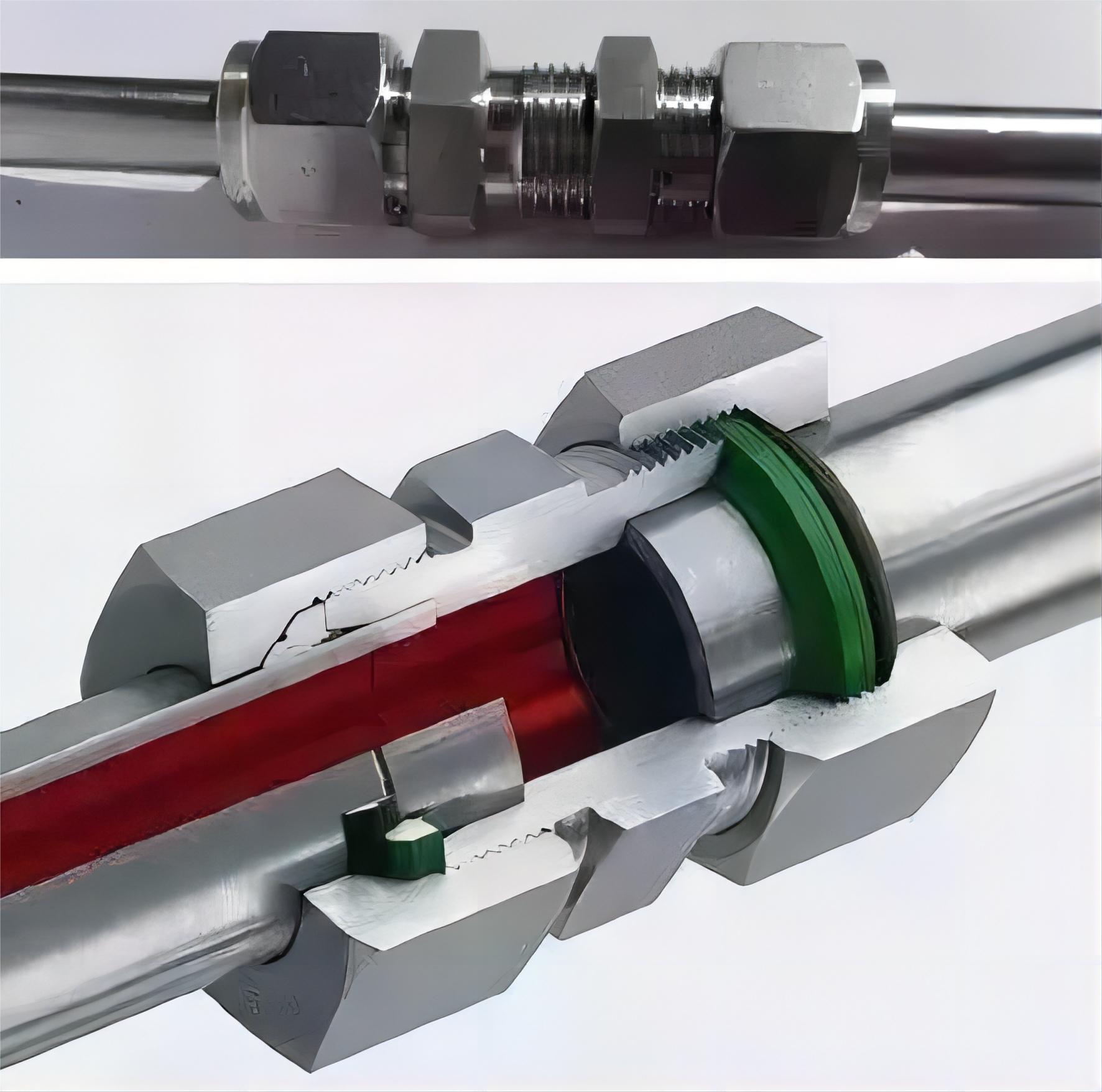

5.FimpazamoCunxibelelwano

Imibhobho ye-aluminium-plastiki edityanisiweyo idla ngokugqunywa ngee-ferrules ezinemisonto. Izifakelo zinamathela esiphelweni sombhobho, emva koko izifakelo zingena esiphelweni, ngesitshixo sokuqinisa izifakelo kunye neenati zinokuba njalo. Uqhagamshelo lombhobho wethusi lungasetyenziswa nakwi-ferrule enemisonto.

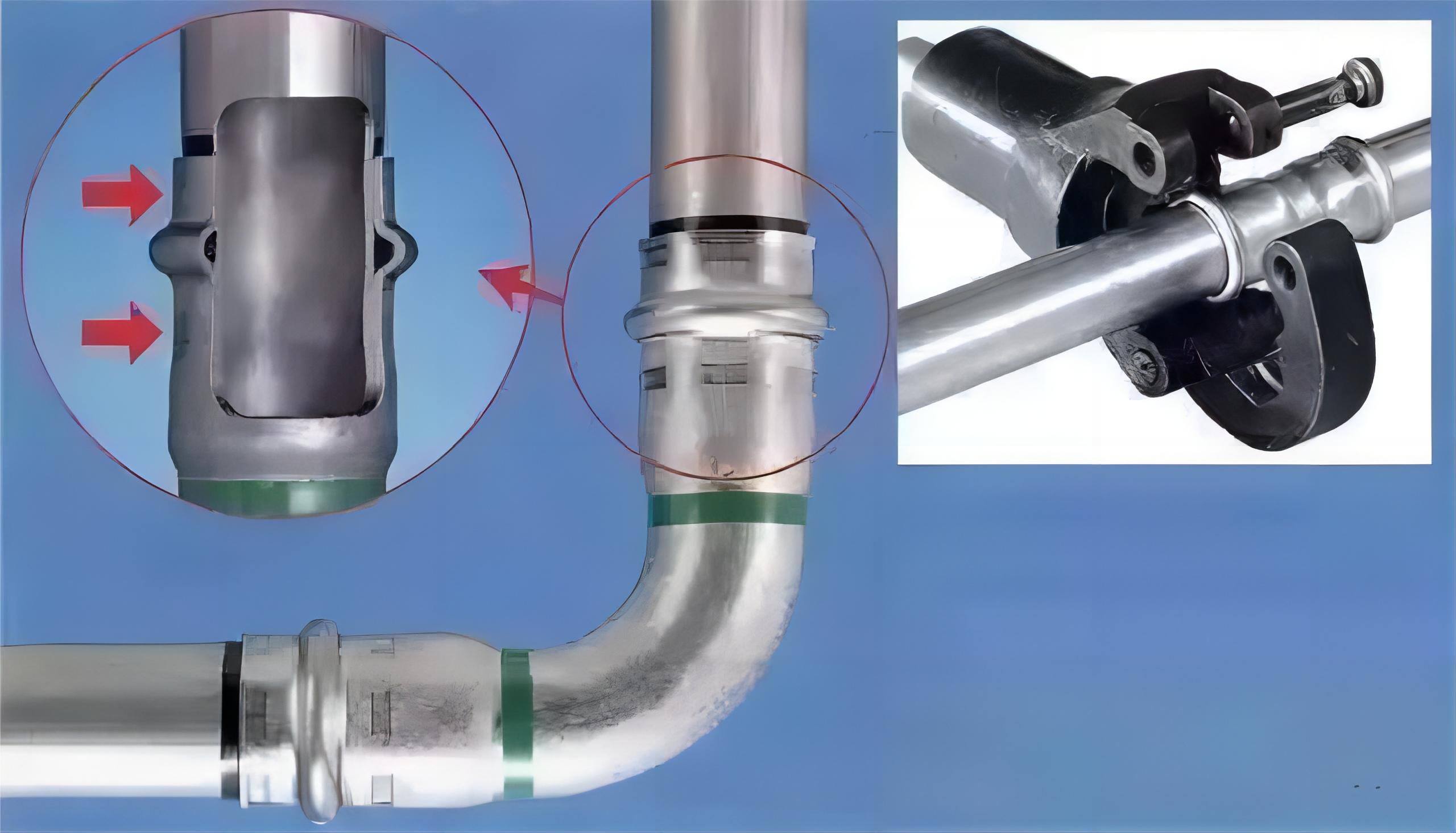

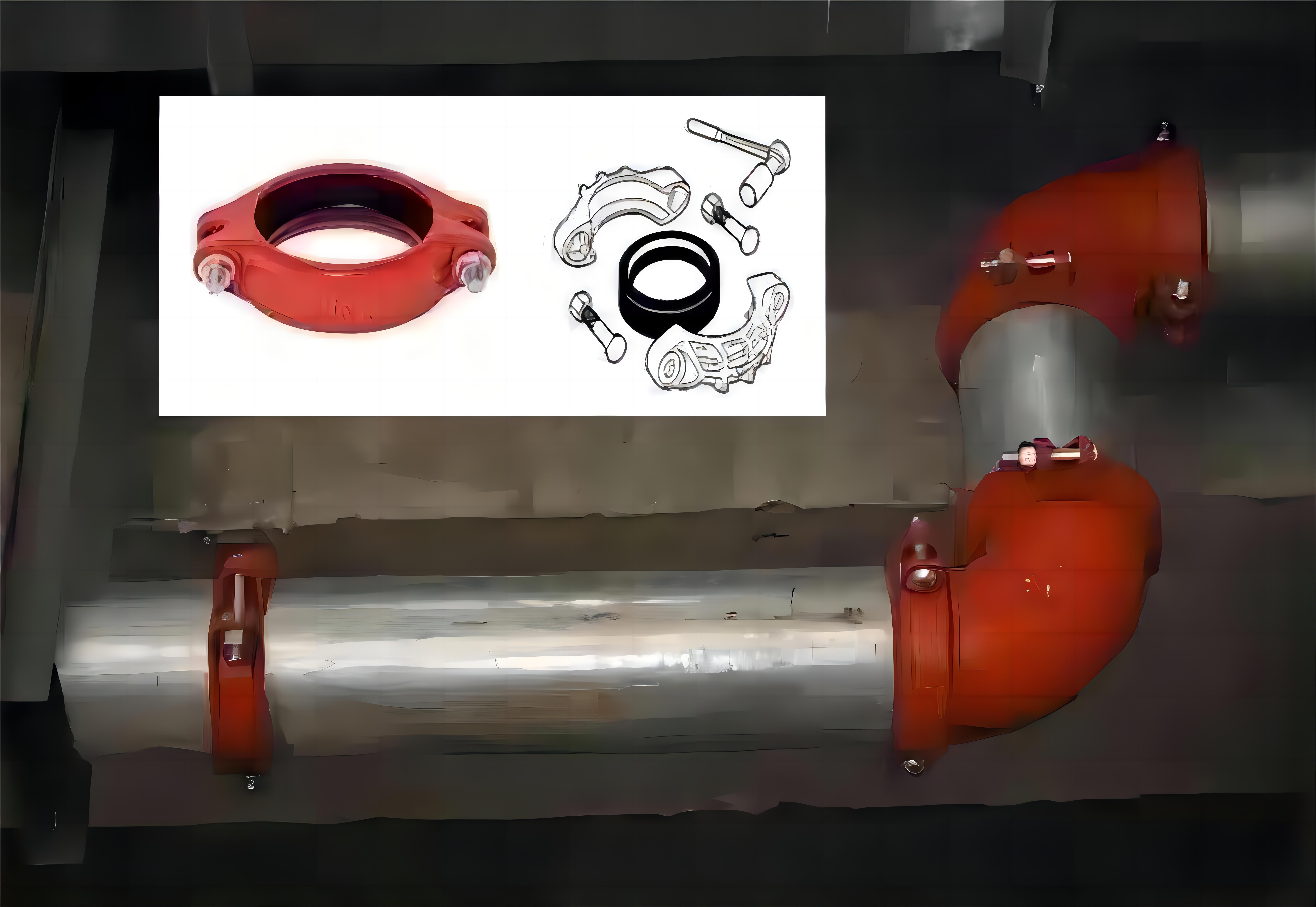

6. Uqhagamshelo lweClamp

Iteknoloji yoqhagamshelo lwezixhobo zoxinzelelo lwentsimbi engagqwaliyo ukuze ithathe indawo yeteknoloji yoqhagamshelo lwemibhobho yamanzi eneentambo, edibeneyo, encamathiselweyo kunye nezinye iindlela zemveli zoqhagamshelo lwemibhobho yamanzi, ngokukhuselwa kococeko lwamanzi, ukumelana nokugqwala, ubomi benkonzo ende njalo njalo, ukwakhiwa kwendandatho yokutywina ekhethekileyo enezixhobo ezizodwa zesokhethi kunye noqhagamshelo lwemibhobho, ukusetyenziswa kwezixhobo ezikhethekileyo zokuqinisa umlomo wombhobho ukuze udlale isiphumo sokutywina nokuqinisa, ukwakhiwa kofakelo lunxibelelwano olulula, oluthembekileyo nolunengqiqo ngokwezoqoqosho kunye nezinye izibonelelo.

7. Uqhagamshelo lweHotmelt

Indlela yokudibanisa umbhobho we-PPR kukudibanisa ubushushu ngesixhobo sokudibanisa ubushushu.

8. Uqhagamshelo lweGroove

Ixesha lokuthumela: Novemba-06-2023