Intshayelelo:

I-API 5L yinkcazo esemgangathweni esekwe yi-American Petroleum Institute (API) yeepayipi zentsimbi ezingenamthungo nezihlanganisiweyo ezisetyenziswa kwiinkqubo zothutho ngaphakathi kwimizi-mveliso yepetroleum kunye negesi yendalo. I-Womic Steel, umenzi ophambili weepayipi zomgca we-API 5L, inikezela uluhlu olubanzi lweemveliso ezihlangabezana namanqanaba kunye neenkcukacha ezahlukeneyo. Eli nqaku libonelela ngothelekiso oluneenkcukacha lwendlela yokwakheka kweekhemikhali, iipropati zoomatshini, kunye nemigangatho yovavanyo yamanqanaba ahlukeneyo e-API 5L, zombini i-PSL1 kunye ne-PSL2 kwiintlobo ezintathu zeepayipi: i-ERW (Electric Resistance Welded), i-LSAW (Longitudinal Submerged Arc Welded), kunye ne-SMLS (Seamless).

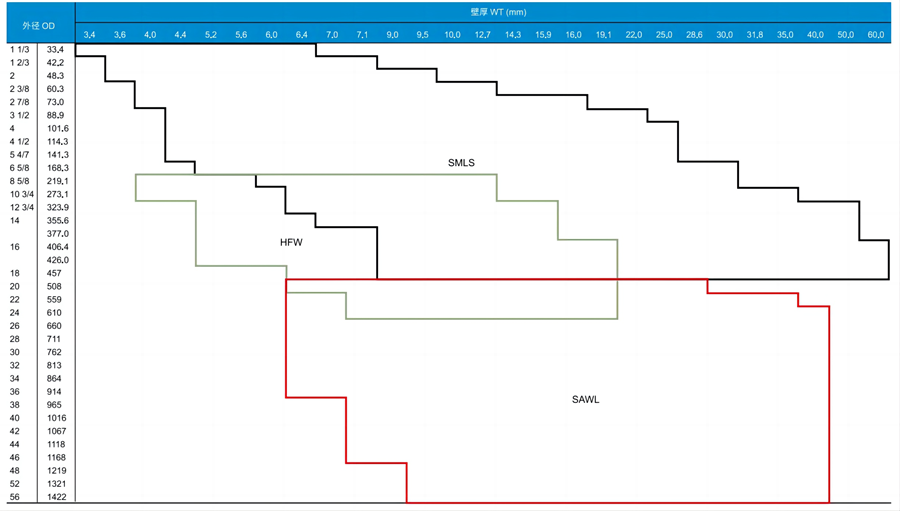

Amandla eMveliso kunye noLuhlu:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Ubuncinci mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| ii-SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| I-SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Ukunyamezelana kobubanzi bangaphandle

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| I-API Spec SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ± 2.0mm | ± 1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Qaphela: U-D bububanzi obuqhelekileyo bangaphandle bombhobho.

Ukunyamezela Ubukhulu Bodonga

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| I-API Spec I-ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst<25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

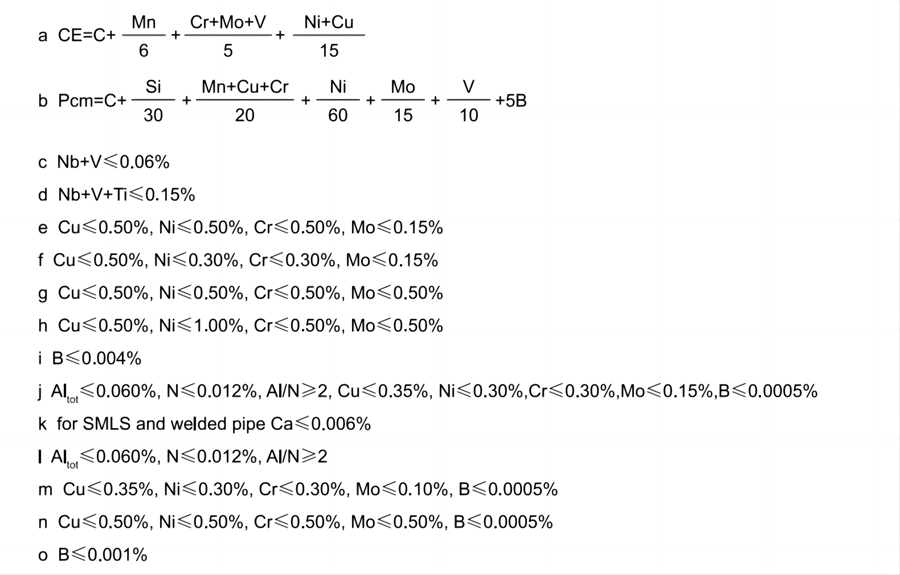

Uhlalutyo lweeKhemikhali

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | I-Pcm | 备注 |

| ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | |||||

| I-API SPEC 5L | 无缝管 | I-PSL1 | L210 okanye A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 okanye B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 okanye X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| I-L320 okanye i-X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-L360 okanye i-X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 okanye X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 okanye X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 okanye X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 okanye X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-PSL2 | L245N okanye BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | ICFO | ||

| L290N okanye X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N okanye X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N okanye X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N okanye X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N okanye X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Njengoko kuvunyelwene | d,g,o | ||||

| I-L245Q okanye i-BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L290Q okanye i-X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q okanyeX46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 okanye ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L390Q okanye i-X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q okanye X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L450Q okanye i-X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L485Q okanye i-X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L555Q okanye i-X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Njengoko kuvunyelwene | Mholo | ||||

| 酸性服 | I-L245NS okanye i-BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| I-L290NS okanye i-X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| I-L320NS okanye i-X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | u-dj,k | |||

| I-L360NS okanye i-X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| I-L245QS okanye i-BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| I-L290QS okanye i-X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| I-L320QS okanye i-X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| I-L360QS okanye i-X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| I-L390QS okanye i-X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| I-L415QS okanye i-X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | u-dj,k | |||

| I-L450QS okanye i-X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| I-L485QS okanye i-X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | I-CEa | I-Pcm | 备注 |

| ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO okanye i-BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,I,m |

| L290NO okanye X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO okanye X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, Mna, m | |||

| L360NO okanye X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, Mna | |||

| I-L245QO okanye i-BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| I-L290QO okanye i-X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| I-L320QO okanye i-X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| I-L360QO okanye i-X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| I-L390QO okanye i-X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| I-L415QO okanye i-X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| I-L455QO okanye i-X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 okanye X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| I-L555QO okanye i-X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Njengoko kuvunyelwene | d,I,n | ||||

| 焊管 | I-PSL1 | L245 okanye B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 okanyeX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 okanyeX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-L360 okanye i-X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 okanyeX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 okanyeX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 okanye X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 okanye X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-PSL2 | 1245M okanye iBM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| I-L290M okanye i-X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L320M okanye i-X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L360M okanye i-X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| I-L390M okanye i-X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M okanye X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L450M okanye i-X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M okanye X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L555M okanye i-X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | I-CEa | I-Pcm | 备注 |

| ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | |||||

| I-API SPEC 5L | 焊管 | 酸性服 | I-L245MS okanye i-BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| I-L290MS okanye i-X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| I-L320MS okanye i-X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| I-L360MS okanye i-X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| I-L390MS okanye i-X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| I-L415MS okanye i-X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| I-L450MS okanye i-X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| I-L485MS okanye i-X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | u-dj,k | |||

| 海上服 | I-L245MO okanye i-BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| I-L290MO okanye i-X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| I-L320MO okanye i-X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Mna, m | |||

| L360MO okanye X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| I-L390MO okanye i-X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO okanye X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| I-L450MO okanye i-X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO okanye X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| I-L555MO okanye i-X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| I-API SPEC 5L | I-PSL1 | L210 okanye A | Ubuncinci | 210 | 335 | a |

| 335 |

| L245 okanye B | Ubuncinci | 245 | 415 | a |

| 415 | ||

| L290 okanye X42 | Ubuncinci | 290 | 415 | a |

| 415 | ||

| I-L320 okanye i-X46 | Ubuncinci | 320 | 435 | a |

| 435 | ||

| I-L360 okanye i-X52 | Ubuncinci | 360 | 460 | a |

| 460 | ||

| L390 okanye X56 | Ubuncinci | 390 | 490 | a |

| 490 | ||

| L415 okanye X60 | Ubuncinci | 415 | 520 | a |

| 520 | ||

| L450 okanye X65 | Ubuncinci | 450 | 535 | a |

| 535 | ||

| L485 okanye X70 | Ubuncinci | 485 | 570 | a |

| 570 | ||

| I-PSL2 | L245N okanye BN | Ubuncinci | 245 | 415 | a |

| 415 | |

| Ubuninzi | 450 | 655 |

| 0.93 |

| |||

| L290N okanye X42N | Ubuncinci | 290 | 415 | a |

| 415 | ||

| Ubuninzi | 495 | 655 |

| 0.93 |

| |||

| L320N okanye X46N | Ubuncinci | 320 | 435 | a |

| 435 | ||

| Ubuninzi | 525 | 655 |

| 0.93 |

| |||

| L360N okanye X52N | Ubuncinci | 360 | 460 | a |

| 460 | ||

| Ubuninzi | 530 | 760 |

| 0.93 |

| |||

| L390N okanye X56N | Ubuncinci | 390 | 490 | a |

| 490 | ||

| Ubuninzi | 545 | 760 |

| 0.93 |

| |||

| L415N okanye X60N | Ubuncinci | 415 | 520 | a |

| 520 | ||

| Ubuninzi | 565 | 760 |

| 0.93 |

| |||

| I-L450Q okanye i-X65Q | Ubuncinci | 450 | 535 | a |

| 535 | ||

| Ubuninzi | 600 | 760 |

| 0.93 |

| |||

| I-L485Q okanye i-X70Q | Ubuncinci | 485 | 570 | a |

| 570 | ||

| Ubuninzi | 635 | 760 |

| 0.93 |

| |||

| I-L555Q okanye i-X80Q | Ubuncinci | 555 | 625 | a |

| 625 | ||

| Ubuninzi | 705 | 825 |

| 0.93 |

| |||

| I-L625M okanye i-X90M | Ubuncinci | 625 | 695 | a |

| 695 | ||

| Ubuninzi | 775 | 915 |

| 0.95 |

| |||

| I-L690M okanye i-X100M | Ubuncinci | 690 | 760 | a |

| 760 | ||

| Ubuninzi | 840 | 990 |

| 0.97 |

| |||

| I-L830M okanye i-X120M | Ubuncinci | 830 | 915 | a |

| 915 | ||

| Ubuninzi | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| I-API SPEC 5L | 酸性服 | I-L245NS okanye i-BNS | Ubuncinci | 245 | 415 | a |

| 415 |

| Ubuninzi | 450 | 655 |

| 0.93 |

| |||

| I-L290NS okanye i-X42NS | Ubuncinci | 290 | 415 | a |

| 415 | ||

| Ubuninzi | 495 | 655 |

| 0.93 |

| |||

| I-L320NS okanye i-X46NS | Ubuncinci | 320 | 435 | a |

| 435 | ||

| Ubuninzi | 525 | 655 |

| 0.93 |

| |||

| I-L360NS okanye i-X52NS | Ubuncinci | 360 | 460 | a |

| 460 | ||

| Ubuninzi | 530 | 760 |

| 0.93 |

| |||

| I-L390QS okanye i-X56QS | Ubuncinci | 390 | 490 | a |

| 490 | ||

| Ubuninzi | 545 | 760 |

| 0.93 |

| |||

| I-L415QS okanye i-X60QS | Ubuncinci | 415 | 520 | a |

| 520 | ||

| Ubuninzi | 565 | 760 |

| 0.93 |

| |||

| I-L450QS okanye i-X65QS | Ubuncinci | 450 | 535 | a |

| 535 | ||

| Ubuninzi | 600 | 760 |

| 0.93 |

| |||

| I-L485QS okanye i-X70QS | Ubuncinci | 485 | 570 | a |

| 570 | ||

| Ubuninzi | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO okanye i-BNO | Ubuncinci | 245 | 415 | a | - | 415 | |

| Ubuninzi | 450 | 655 |

| 0.93 |

| |||

| L290NO okanye X42NO | Ubuncinci | 290 | 415 | a |

| 415 | ||

| Ubuninzi | 495 | 655 |

| 0.93 |

| |||

| L320NO okanye X46NO | Ubuncinci | 320 | 435 | a |

| 435 | ||

| Ubuninzi | 520 | 655 |

| 0.93 |

| |||

| L360NO okanye X52NO | Ubuncinci | 360 | 460 | a |

| 460 | ||

| Ubuninzi | 525 | 760 |

| 0.93 |

| |||

| I-L390QO okanye i-X56QO | Ubuncinci | 390 | 490 | a |

| 490 | ||

| Ubuninzi | 540 | 760 |

| 0.93 |

| |||

| I-L415QO okanye i-X60QO | Ubuncinci | 415 | 520 | a | - | 520 | ||

| Ubuninzi | 565 | 760 |

| 0.93 |

| |||

| I-L450QO okanye i-X65QO | Ubuncinci | 450 | 535 | a | - | 535 | ||

| Ubuninzi | 570 | 760 |

| 0.93 |

| |||

| L485Q0 okanye X70Q0 | Ubuncinci | 485 | 570 | a |

| 570 | ||

| Ubuninzi | 605 | 760 |

| 0.93 |

| |||

| I-L555QO okanye i-X80QO | Ubuncinci | 555 | 625 | a |

| 625 | ||

| Ubuninzi | 675 | 825 |

| 0.93 |

Qaphela: a: Ubuncinane bokwandiswa kusetyenziswa le nxaki ilandelayo: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 okanye X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 okanye X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 okanye X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 okanye X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Qaphela: (1) Amaxabiso akwitheyibhile afanelekela isampuli epheleleyo yobukhulu obupheleleyo.

(2) Ixabiso elingaphakathi kwebrakethi lixabiso elinye elincinci, ibrakethi engaphandle lixabiso eliphakathi.

(3) Ubushushu bovavanyo: 0°C.

Imigangatho yoVavanyo:

Iipayipi zomgca ze-API 5L ezenziwe yiWomic Steel zivavanyelwa nzima ukuqinisekisa ukuba ziyahlangabezana nemigangatho ephezulu. Imigangatho yovavanyo ibandakanya:

Uhlalutyo lweeKhemikhali:

Ukwakheka kweekhemikhali zentsimbi kuyahlalutywa ukuqinisekisa ukuba iyahlangabezana neemfuno zenkcazo ye-API 5L.

Uhlalutyo lweekhemikhali lwenziwa kusetyenziswa i-spectrometer yokufunda ngqo ukuze kuchongwe ngokuchanekileyo ukwakheka kwezinto zentsimbi.

Uvavanyo lweMishini:

Iimpawu zoomatshini ezifana namandla okuvelisa, amandla okutsalwa, kunye nokwandiswa ziyavavanywa ukuqinisekisa ukuba ziyahlangabezana neemfuno ezichaziweyo.

Uvavanyo loomatshini lwenziwa kusetyenziswa umatshini wokuvavanya ukuxinana weetoni ezingama-60 ukulinganisa amandla kunye nokuqina kwentsimbi.

Uvavanyo lwe-Hydrostatic:

Uvavanyo lwe-hydrostatic lwenziwa ukujonga ukuthembeka kombhobho nokuqinisekisa ukuba unako ukumelana neemfuno zoxinzelelo zesicelo sawo.

Imibhobho izaliswe ngamanzi kwaye iphantsi koxinzelelo, ubude bovavanyo kunye namanqanaba oxinzelelo achazwe yimigangatho ye-API 5L.

Uvavanyo Olungonakalisiyo (NDT):

Iindlela ze-NDT ezifana novavanyo lwe-ultrasonic (UT) kunye novavanyo lwe-magnetic particle (MT) zisetyenziselwa ukufumanisa naziphi na iziphene okanye ukungaqhubeki kombhobho.

I-UT isetyenziselwa ukuchonga iziphene zangaphakathi, ngelixa i-MT isetyenziselwa ukufumanisa iziphene zomphezulu.

Uvavanyo lweMpembelelo:

Uvavanyo lwempembelelo lwenziwa ukuvavanya ukuqina kwentsimbi kumaqondo obushushu aphantsi.

Uvavanyo lweCharpy impact lusetyenziswa rhoqo ukulinganisa amandla empact afunxwa yintsimbi.

Uvavanyo loBulukhuni:

Uvavanyo lokuqina lwenziwa ukuze kuvavanywe ubulukhuni bentsimbi, nto leyo enokubonisa amandla ayo kunye nokufaneleka kwayo kwizicelo ezithile.

Uvavanyo lokuqina lweRockwell ludla ngokusetyenziswa ukulinganisa ubunzima bentsimbi.

Uvavanyo lweMicrostructure:

Uvavanyo lwesakhiwo esincinci lwenziwa ukuze kuvavanywe isakhiwo sengqolowa kunye nomgangatho uphela wentsimbi.

I-microscope yesinyithi isetyenziselwa ukuhlola isakhiwo sentsimbi kunye nokuchonga naziphi na izinto ezingaqhelekanga.

Ngokulandela le migangatho yovavanyo oluqatha, iWomic Steel iqinisekisa ukuba imibhobho yayo yomgca we-API 5L iyahlangabezana neemfuno zomgangatho ophezulu kwaye ibonelela ngokusebenza okuthembekileyo kwizicelo ezahlukeneyo zoshishino.

Inkqubo yeMveliso:

1. Imibhobho yentsimbi engenamthungo:

- Ukukhethwa kwezinto eziluhlaza: Iibhilethi zentsimbi ezingqukuva ezikumgangatho ophezulu zikhethwa ukuze kuveliswe imibhobho yentsimbi engenamthungo.

- Ukufudumeza nokubhoboza: Iibhilethi zifudunyezwa kubushushu obuphezulu zize zibhobozwe ukuze zenze iqokobhe elingenanto.

- Ukuqengqeleka nobukhulu: Iqokobhe elihlatyiweyo liyaqengqeleka lize lolulwe ukuya kububanzi nobukhulu obufunekayo.

- Unyango lobushushu: Iipayipi zifakwa kwiinkqubo zonyango lobushushu ezifana nokuqhoboshelwa okanye ukulungiswa ukuze kuphuculwe iimpawu zazo zoomatshini.

- Ukugqitywa: Iipayipi zigqityezelwa iinkqubo zokugqiba ezifana nokulungisa, ukusika, kunye nokuhlolwa.

- Uvavanyo: Iipayipi zivavanyelwa ngeendlela ezahlukeneyo, kuquka uvavanyo lwe-hydrostatic, uvavanyo lwe-ultrasound, kunye novavanyo lwe-eddy current, ukuqinisekisa umgangatho wazo.

- Unyango Lomphezulu: Iipayipi zingagqunywa okanye zilungiswe ukuze kuthintelwe ukugqwala nokuphucula inkangeleko yazo.

- Ukupakishwa nokuThunyelwa: Iipayipi zipakishwa ngononophelo kwaye zithunyelwa kubathengi.

2. Iipayipi zentsimbi ze-LSAW (Longitudinal Submerged Arc Welding):

- Ukulungiswa kwepleyiti: Iipleyiti zentsimbi ezikumgangatho ophezulu zilungiselelwa ukuveliswa kweepayipi ze-LSAW.

- Ukwakheka: Iipleyiti zenziwe zibe yimo "U" kusetyenziswa umatshini ogobayo kwangaphambili.

- Ukuwelda: Iipleyiti ezimile okwe-"U" emva koko zidityaniswa kusetyenziswa inkqubo yokuwelda ye-arc engaphantsi komhlaba.

- Ukwandiswa: Umthungo odityanisiweyo wandiswa ukuya kububanzi obufunekayo kusetyenziswa umatshini wokwandisa wangaphakathi okanye wangaphandle.

- Ukuhlolwa: Imibhobho iyahlolwa ukuze kujongwe iziphene kunye nokuchaneka kobukhulu bayo.

- Uvavanyo lwe-Ultrasonic: Iipayipi ziyavavanywa nge-ultrasound ukuze kufunyanwe naziphi na iziphene zangaphakathi.

- Ukujija: Iziphelo zemibhobho zijijelwe ukuze zijijelwe.

- Ukwaleka kunye nokuMakisha: Imibhobho ingafakwa ipeyinti kwaye iphawulwe ngokweemfuno zabathengi.

- Ukupakishwa nokuThunyelwa: Iipayipi ziyapakishwa kwaye zithunyelwe kubathengi.

3. Iipayipi zentsimbi ze-HFW (i-High-Frequency Welding):

- Ukulungiswa kweKhoyili: Iikhoyili zentsimbi zilungiselelwa ukuveliswa kwemibhobho ye-HFW.

- Ukwenziwa kunye nokuWelda: Iikhoyili zenziwe zibe yimo ye-cylindrical zize emva koko ziweldwe kusetyenziswa ukuwelda okuqhelekileyo.

- Ukufudumeza umthungo we-Weld: Umthungo we-weld ufudunyezwa ukuya kubushushu be-welding kusetyenziswa ukufudumeza kwe-induction okuphindaphindwayo.

- Ubungakanani: Umbhobho odibeneyo ulingana nobubanzi kunye nobukhulu obufunekayo.

- Ukusika kunye nokuBeveling: Umbhobho unqunyulwa ngobude obufunekayo kwaye iziphelo ziyabevelingiswa ukuze kudityaniswe.

- Ukuhlolwa: Imibhobho iyahlolwa ukuze kujongwe iziphene kunye nokuchaneka kobukhulu bayo.

- Uvavanyo lwe-Hydrostatic: Iipayipi zivavanywa ukuqina kunye nokuvuza kusetyenziswa uvavanyo lwe-hydrostatic.

- Ukwaleka kunye nokuMakisha: Imibhobho igqunywe kwaye iphawulwe ngokweemfuno zabathengi.

- Ukupakishwa nokuThunyelwa: Iipayipi ziyapakishwa kwaye zithunyelwe kubathengi.

Ezi nkqubo zemveliso zineenkcukacha ziqinisekisa umgangatho ophezulu kunye nokuthembeka kwemibhobho yentsimbi engenamthungo, i-LSAW, kunye ne-HFW eyenziwe yiWomic Steel, ehlangabezana neemfuno ezingqongqo zamashishini ahlukeneyo.

Unyango Lomphezulu:

Unyango lomphezulu wentsimbi yombhobho lubalulekile ekuphuculeni ukumelana kwayo nokugqwala kunye nobomi bayo benkonzo. I-Womic Steel isebenzisa iindlela ezahlukeneyo zonyango lomphezulu kuxhomekeke kwiimfuno ezahlukeneyo zabathengi, kuquka:

1. I-Hot-dip Galvanizing: Umbhobho wentsimbi untywiliselwa kwi-zinc enyibilikisiweyo ukuze kwenziwe umaleko okhuselayo we-zinc-iron alloy, nto leyo ephucula ukumelana kwayo nokugqwala. I-hot-dip galvanizing ifanelekile kwiipayipi zesiqhelo neziphantsi koxinzelelo.

2. Iingubo ezichasene nokugqwala: Iingubo ezixhaphakileyo ezichasene nokugqwala ziquka iingubo ze-epoxy, iingubo ze-polyethylene, kunye neengubo ze-polyurethane. Ezi ngubo zithintela ngokufanelekileyo ukugqwala kunye nokugqwala kumphezulu wombhobho wentsimbi, zisolula ubomi bawo benkonzo.

3. Ukuqhumisa ngesanti: Ukuqhumisa ngesantya esiphezulu kusetyenziselwa ukucoca umbhobho wentsimbi, ukususa umhlwa kunye nokungcola kumphezulu, okubonelela ngesiseko esihle sonyango olulandelayo lokugquma.

4. Unyango Lokugquma: Umphezulu wombhobho wentsimbi unokugqunywa ngeepeyinti ezichasene nokugqwala, iipeyinti ze-asphalt, kunye nezinye izinto zokugquma ukuze kuphuculwe ukumelana nokugqwala, ezifanelekileyo kwiipayipi ezingaphantsi komhlaba kunye neepayipi kwiindawo zaselwandle.

Ezi ndlela zonyango lomphezulu zikhusela ngokufanelekileyo intsimbi yepayipi ekungcoleni nasekonakaleni, ziqinisekisa ukuthembeka kwayo nokuqina kwayo kwiindawo ezahlukeneyo ezinzima.

Ukupakishwa kunye nokuThuthwa:

I-Womic Steel iqinisekisa ukupakishwa okukhuselekileyo kunye nokuthuthwa okuthembekileyo kwentsimbi yepayipi, inikezela ngeendlela eziguquguqukayo zokuhlangabezana neemfuno ezahlukeneyo zabathengi:

1. Imithwalo Emininzi: Kwiiodolo ezinkulu, intsimbi yepayipi ingathunyelwa ngobuninzi kusetyenziswa iinqanawa ezikhethekileyo zokuthwala impahla. Intsimbi ifakwa ngqo kwindawo yokugcina inqanawa ngaphandle kokupakishwa, ifanelekile ukuthuthwa ngobuninzi obungabizi kakhulu.

2. I-LCL (Ingaphantsi Komthwalo Wesikhongozeli): Kwiiodolo ezincinci, intsimbi yepayipi ingathunyelwa njengemithwalo ye-LCL, apho iiodolo ezininzi ezincinci zidityaniswe kwisikhongozeli esinye. Le ndlela ingabizi kakhulu kwiindleko ezincinci kwaye inikezela ngeeshedyuli zokuhambisa eziguquguqukayo ngakumbi.

3. I-FCL (Umthwalo weContainer epheleleyo): Abathengi banokukhetha ukuthunyelwa kwe-FCL, apho i-container epheleleyo inikezelwe kwi-odolo yabo. Le ndlela inika amaxesha okuthutha akhawulezayo kwaye inciphisa umngcipheko wokonakala ngexesha lokuphathwa.

4. Uthutho Lomoya: Kwiiodolo ezingxamisekileyo, uthutho lomoya luyafumaneka ukuze luthunyelwe ngokukhawuleza. Nangona lubiza kakhulu kunothutho lolwandle, uthutho lomoya lubonelela ngothutho olukhawulezayo noluthembekileyo lothutho oluhamba ngexesha.

I-Womic Steel iqinisekisa ukuba zonke izinto ezithunyelwayo zipakishwe ngokukhuselekileyo ukuze kuthintelwe umonakalo ngexesha lokuthuthwa. Intsimbi idla ngokusongelwa ngezinto zokukhusela kwaye iqiniswe kwiikhonteyina okanye kwiipalethi ukuqinisekisa uzinzo ngexesha lokuthuthwa. Ukongeza, inkampani isebenzisana ngokusondeleyo namaqabane okuthutha athembekileyo ukuqinisekisa ukuhanjiswa ngexesha elifanelekileyo kunye nolawulo olufanelekileyo lwezothutho.

Imeko zesicelo:

Iipayipi zomgca ze-API 5L eziveliswa yiWomic Steel zisetyenziswa kakhulu kumashishini epetroleum kunye negesi yendalo ekuthuthweni kweoyile, igesi, kunye nezinye izinto eziphumayo. Zikwasetyenziswa nakwamanye amashishini ahlukeneyo afana nokucubungula iikhemikhali, ukuvelisa umbane, kunye nokwakha.

Isiphelo:

I-Womic Steel ngumvelisi othembekileyo weepayipi zomgca ze-API 5L, enikezela ngeemveliso ezikumgangatho ophezulu ezihlangabezana neemfuno ezingqongqo zemizi-mveliso yepetroliyam negesi yendalo. Igxile kumgangatho, ukuthembeka, kunye nokwaneliseka kwabathengi, i-Womic Steel iyaqhubeka nokuba lukhetho olukhethwayo kubathengi kwihlabathi liphela.

Ixesha leposi: Matshi-22-2024