I-ASME B16.9 vs. ASME B16.11: Uthelekiso olupheleleyo kunye neenzuzo ze-Butt Weld Fittings

Wamkelekile kwiWomic Steel Group!

Xa ukhetha izixhobo zokufaka iipayipi zokusetyenziswa kwemizi-mveliso, ukuqonda umahluko ophambili phakathi kwemigangatho ye-ASME B16.9 kunye ne-ASME B16.11 kubalulekile. Eli nqaku libonelela ngothelekiso oluneenkcukacha lwale migangatho mibini isetyenziswa kakhulu kwaye ligxininisa iingenelo zezixhobo zokufaka ii-butt weld kwiinkqubo zepayipi.

Ukuqonda izixhobo zombhobho

Ukufakelwa kwepayipi yinxalenye esetyenziswa kwinkqubo yepayipi ukutshintsha icala, uqhagamshelo lwamasebe, okanye ukuguqula ububanzi bepayipi. Ezi zixhobo zidityaniswe ngoomatshini kwinkqubo kwaye ziyafumaneka ngobukhulu obahlukeneyo kunye neeshedyuli ukuze zihambelane neepayipi ezifanelekileyo.

Iintlobo zeZixhobo zoMbhobho

Izixhobo zokufaka iipayipi zahlulwe zibe ngamaqela amathathu aphambili:

Izixhobo zokuWelda ngeButt (BW):Ezi fittings, ezilawulwa yi-ASME B16.9, zenzelwe ukusetyenziswa kwe-welding kwaye ziquka iintlobo ezilula nezimelana nokugqwala ezenziwe ngokwe-MSS SP43.

Izixhobo zeSocket Weld (SW):Ezi fittings zichazwe phantsi kwe-ASME B16.11, zifumaneka kwiireyithingi zoxinzelelo zeKlasi 3000, 6000, kunye ne-9000.

Izixhobo ezifakwe imisonto (THD):Kwakhona kuchazwe kwi-ASME B16.11, ezi fittings zihlelwe phantsi kweClass 2000, 3000, kunye ne-6000 ratings.

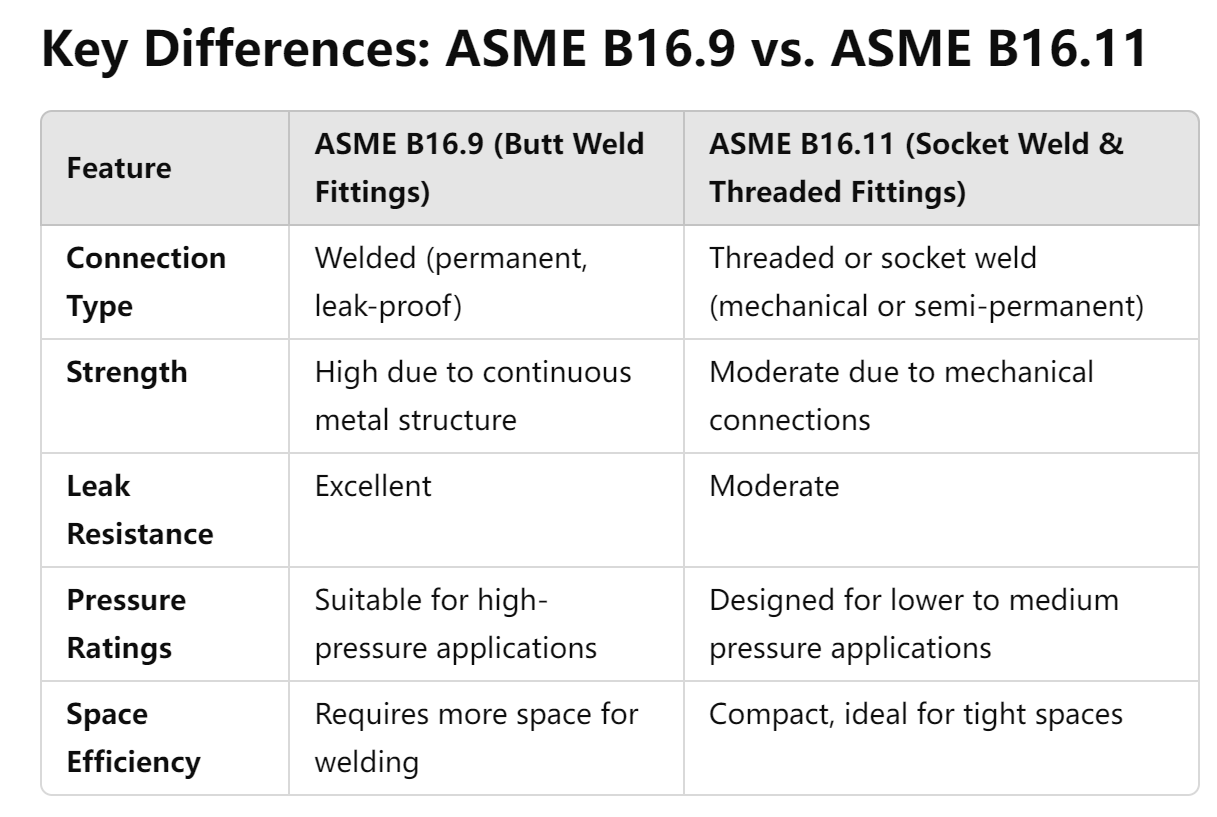

Umahluko oPhambili: ASME B16.9 vs. ASME B16.11

Uphawu

I-ASME B16.9 (Izixhobo zokuWelda iiButt)

I-ASME B16.11 (Izihlanganisi zeSocket Weld kunye neThreaded Fittings)

Uhlobo loQhagamshelo

I-Welded (ihlala ihleli, ayivuzi)

I-weld enemisonto okanye yesokhethi (eyenziwe ngoomatshini okanye esisigxina kancinci)

Amandla

Iphezulu ngenxa yesakhiwo sesinyithi esiqhubekayo

Iphakathi ngenxa yoqhagamshelo loomatshini

Ukumelana nokuvuza

Igqwesile

Iphakathi

Uvavanyo loxinzelelo

Ifanelekile kwizicelo ezisebenzisa uxinzelelo oluphezulu

Yenzelwe ukusetyenziswa koxinzelelo oluphantsi ukuya koluphakathi

Ukusebenza kakuhle kwesithuba

Ifuna indawo engakumbi yokuwelda

Incinci, ifanelekile kwiindawo ezixineneyo

Izixhobo zokuWelda zeButt ezisemgangathweni phantsi kwe-ASME B16.9

Ezi zilandelayo zizixhobo zokuwelda ezisemgangathweni ezigutyungelwe yi-ASME B16.9:

Ingqiniba ende engama-90° (LR)

Ingqiniba ende engama-45° (LR)

Ingqiniba emfutshane ye-90° (SR)

Ingqiniba ende eyi-180° (LR)

Ingqiniba emfutshane ye-180° (SR)

I-Equal Tee (EQ)

Ukunciphisa iTie

I-Concentric Reducer

Ukunciphisa okungaqhelekanga

Isiphetho soMgca

Isiphelo seStub ASME B16.9 kunye neMSS SP43

Iingenelo zeZixhobo zokuWelda zeButt

Ukusebenzisa izixhobo zokuwelda ezingasemva kwinkqubo yemibhobho kunika iingenelo ezininzi:

Iijoyinti ezihlala zihleli, ezingavuziyo: Ukuwelda kuqinisekisa uqhagamshelo olukhuselekileyo noluhlala ixesha elide, okususa ukuvuza.

Ukomelela Kolwakhiwo Oluphuculweyo: Ulwakhiwo lwesinyithi oluqhubekayo phakathi kombhobho kunye nokufakelwa kombane luqinisa ukomelela kwenkqubo iyonke.

Umphezulu Wangaphakathi Othambileyo: Unciphisa ukulahleka koxinzelelo, unciphisa ukuxinana, kwaye unciphisa umngcipheko wokugqwala kunye nokukhukuliseka.

Incinci kwaye Igcina Isithuba: Iinkqubo ezidityanisiweyo zifuna indawo encinci xa kuthelekiswa nezinye iindlela zoqhagamshelo.

Iziphelo Ezinezithende Zokuwelda Okungenamthungo

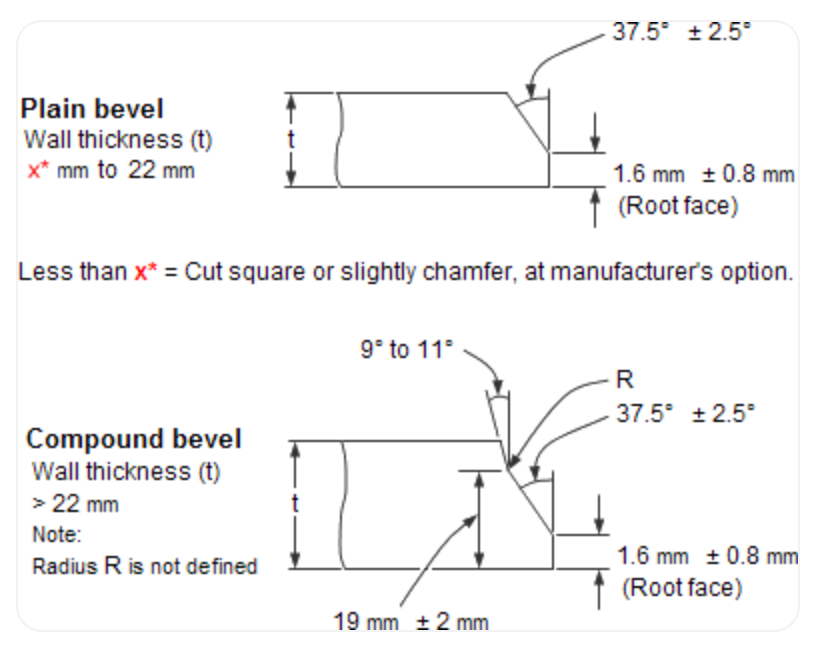

Zonke izixhobo zokuwelda ezingasemva ziza neziphelo ezibekiweyo ukuze kube lula ukuwelda ngaphandle komthungo. Ukubekelelwa kubalulekile ukuqinisekisa ukuba iindawo ezidibeneyo ziqinile, ingakumbi kwiipayipi ezinobukhulu obungaphezulu kodonga:

I-4mm ye-Austenitic Stainless Steel

I-5mm yentsimbi engagqwaliyo yeFerritic

I-ASME B16.25 ilawula ukulungiswa koqhagamshelo lwesiphelo se-buttweld, iqinisekisa ii-bevels ezichanekileyo zokuwelda, ukumila kwangaphandle nangaphakathi, kunye nokunyamezelana okufanelekileyo.

Ukukhethwa kwezinto zokufakelwa kwepayipi

Izinto eziqhelekileyo ezisetyenziswa kwizixhobo zokuwelda ezinqeni ziquka:

Intsimbi yeCarbon

Yenziwe ngentsimbi eshayinayo

Jula i-ayini

I-aluminiyam

Ithusi

Iplastiki (iintlobo ezahlukeneyo)

Izixhobo Ezinemiqolo: Izixhobo ezikhethekileyo ezineengubo zangaphakathi zokuphucula ukusebenza kwazo kwizicelo ezithile.

Izinto ezisetyenziswa kwisixhobo sokufaktha zihlala zikhethwa ukuze zihambelane nezinto ezisetyenziswa kwipayipi ukuqinisekisa ukuba ziyahambelana kwaye zihlala ixesha elide kwimisebenzi yemizi-mveliso.

Malunga ne-WOMIC STEEL GROUP

I-WOMIC STEEL GROUP yinkokheli yehlabathi jikelele ekuveliseni nasekuboneleleni ngezinto zokufakelwa kweepayipi ezikumgangatho ophezulu, iiflanges, kunye nezinto zokufakelwa kweepayipi. Ngokuzibophelela okukhulu ekuveliseni izinto ezintsha, umgangatho, kunye nokwaneliseka kwabathengi, sinikezela ngezisombululo eziphambili kushishino lweoyile negesi, i-petrochemical, ukuveliswa kwamandla, kunye namacandelo okwakha. Uluhlu lwethu olubanzi lwezinto zokufakelwa ze-ASME B16.9 kunye ne-ASME B16.11 luqinisekisa ukusebenza okuthembekileyo kwizicelo ezifuna kakhulu.

Isiphelo

Xa ukhetha izixhobo zokufaka iipayipi, ukuqonda umahluko phakathi kwezixhobo zokufaka iipayipi ze-ASME B16.9 kunye nezixhobo zokufaka iipayipi ze-ASME B16.11 socket weld/threaded kubalulekile. Nangona zombini ezi migangatho zisebenza imisebenzi ebalulekileyo kwiinkqubo zokufaka iipayipi, izixhobo zokufaka iipayipi ze-butt zibonelela ngamandla aphezulu, uqhagamshelo olungenako ukuvuza, kunye nokuqina okuphuculweyo. Ukukhetha izixhobo zokufaka ezifanelekileyo kuya kuqinisekisa ukusebenza okusebenzayo, okuhlala ixesha elide, kunye nokusebenza okukhuselekileyo kwizicelo ezahlukeneyo zoshishino.

Ukuze ufumane izixhobo zokufaka ze-ASME B16.9 kunye ne-ASME B16.11 ezikumgangatho ophezulu, nxibelelana nathi namhlanje! Sinikezela ngoluhlu olubanzi lwezixhobo zokufaka iipayipi ezenzelwe ukuhlangabezana nemigangatho ephezulu yoshishino.

Wamkelekile ukuba unxibelelane nathi ukuze ufumane iinkcukacha ezithe vetshe!

sales@womicsteel.com

Ixesha lokuthumela: Matshi-20-2025