1. Isishwankathelo

I-ASTM A131/A131M yinkcazo yentsimbi yokwakha yeenqanawa. Ibanga le-AH/DH 32 ziintsimbi ezinamandla aphezulu, ezingena-alloy esezantsi ezisetyenziswa kakhulu ekwakheni iinqanawa nakwiindawo zaselwandle.

2. Ukwakheka kweekhemikhali

Iimfuneko zokwakheka kweekhemikhali ze-ASTM A131 Grade AH32 kunye ne-DH32 zezi zilandelayo:

- Ikhabhoni (C): Ubuninzi 0.18%

- IManganese (Mn): 0.90 - 1.60%

- Phosphorus (P): Ubuninzi 0.035%

- I-Sulfur (S): Ubuninzi 0.035%

- I-Silicon (i-Si): 0.10 - 0.50%

- I-Aluminiyam (Al): Ubuncinane yi-0.015%

- I-Copper (Cu): Ubuninzi be-0.35%

- I-Nickel (Ni): Ubuninzi 0.40%

- I-Chromium (Cr): Ubuninzi 0.20%

- Molybdenum (Mo): Ubuninzi 0.08%

- I-Vanadium (V): Ubuninzi be-0.05%

- I-Niobium (Nb): Ubuninzi 0.02%

3. Iipropati zoomatshini

Iimfuneko zepropathi yoomatshini ze-ASTM A131 Grade AH32 kunye ne-DH32 zezi zilandelayo:

- Amandla okuvelisa (umzuzu): 315 MPa (45 ksi)

- Amandla okuThamba: 440 - 590 MPa (64 - 85 ksi)

- Ubude (umzuzu): 22% kwi-200 mm, 19% kwi-50 mm

4. Iipropati zeMpembelelo

- Uvavanyo lweMpembelelo Ubushushu: -20°C

- Amandla empembelelo (umzuzu): 34 J

5. I-Carbon Equivalent

I-Carbon Equivalent (CE) ibalwa ukuvavanya ukudityaniswa kwentsimbi. Ifomula esetyenzisiweyo yile:

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

Kwi-ASTM A131 Grade AH32 kunye ne-DH32, amaxabiso aqhelekileyo e-CE angaphantsi kwe-0.40.

6. Ubukhulu obufumanekayo

Iipleyiti ze-ASTM A131 ze-AH32 kunye ne-DH32 zebanga le-ASTM A131 ziyafumaneka kwiindidi ezahlukeneyo zobukhulu. Ubukhulu obuqhelekileyo buquka:

- Ubukhulu: 4 mm ukuya kwi-200 mm

- Ububanzi: 1200 mm ukuya kwi-4000 mm

- Ubude: 3000 mm ukuya kwi-18000 mm

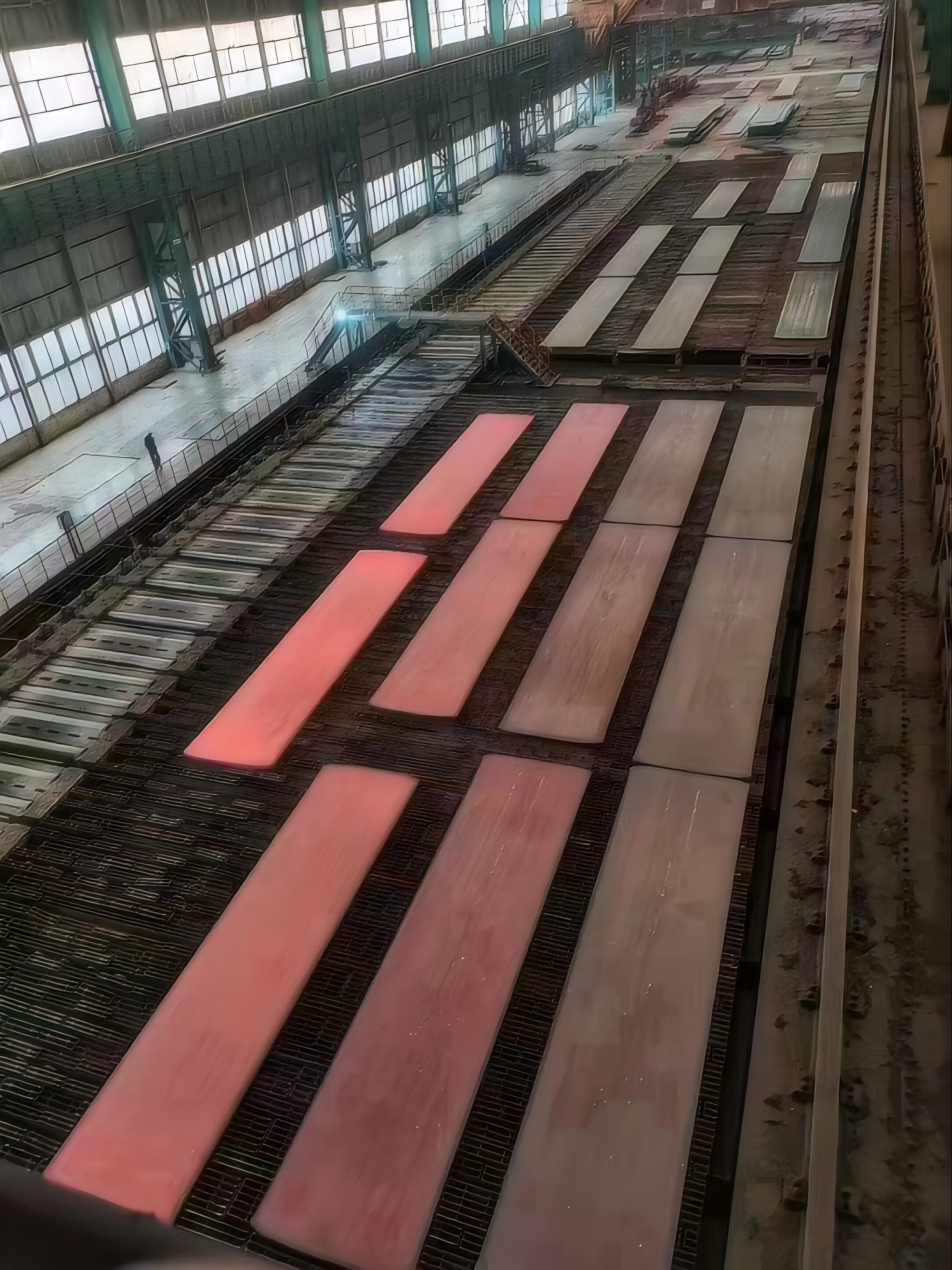

7. Inkqubo yeMveliso

Ukunyibilika: I-Electric Arc Furnace (EAF) okanye i-Basic Oxygen Furnace (BOF).

Ukuqengqeleka Okushushu: Intsimbi iqengqeleka ngokushushu kwiipleyiti.

Unyango lobushushu: Ukuqengqeleka okulawulwayo kulandele ukupholisa okulawulwayo.

8. Unyango Lomphezulu

Ukudubula ngeembumbulu:Isusa isikali semill kunye nokungcola komphezulu.

Ukwaleka:Ipeyintwe okanye igqunywe ngeoyile yokuthintela ukugqwala.

9. Iimfuno zoHlolo

Uvavanyo lwe-Ultrasonic:Ukufumanisa iziphene zangaphakathi.

Ukuhlolwa koMbono:Ngeziphene zomphezulu.

Uhlolo lweMilinganiselo:Iqinisekisa ukunamathela kwimilinganiselo echaziweyo.

Uvavanyo lweMishini:Uvavanyo lokuxinana, impembelelo, kunye nokugoba lwenziwa ukuqinisekisa iimpawu zoomatshini.

10. Imizekelo yesicelo

Ukwakha iinqanawa: Isetyenziselwa ukwakha inqanawa, idekhi, kunye nezinye izakhiwo ezibalulekileyo.

Izakhiwo zaseLwandle: Zifanelekile kumaqonga aselwandle nakwezinye izinto ezisetyenziswa elwandle.

Imbali yoPhuhliso lweWomic Steel kunye namava eProjekthi

I-Womic Steel ibingumdlali obalaseleyo kushishino lwentsimbi kangangeminyaka emininzi, ifumana udumo ngokugqwesa kunye nokuvelisa izinto ezintsha. Uhambo lwethu luqale kwiminyaka engaphezu kwama-30 eyadlulayo, kwaye ukususela ngoko, siye sandisa amandla ethu okuvelisa, samkela ubuchwepheshe obuphambili, kwaye sazibophelela kwimigangatho ephezulu yomgangatho.

Iziganeko ezibalulekileyo

Kwiminyaka yoo-1980:Ukusekwa kweWomic Steel, kugxilwe kwimveliso yentsimbi esemgangathweni ophezulu.

Kwiminyaka yoo-1990:Ukwaziswa kobuchwepheshe bokuvelisa obuphambili kunye nokwandiswa kwezixhobo zokuvelisa.

Kwiminyaka yoo-2000:Sifumene iziqinisekiso ze-ISO, CE, kunye ne-API, nto leyo eqinisa ukuzinikela kwethu kumgangatho.

Kwiminyaka yoo-2010:Ndandise uluhlu lweemveliso zethu ukuze zibandakanye iintlobo ngeentlobo zeeklasi zentsimbi kunye neefom, kuquka iipayipi, iipleyiti, iibhari kunye neengcingo.

Oo-2020:Siqinise ubukho bethu kwihlabathi liphela ngokusebenzisa ubudlelwane obucwangcisiweyo kunye namanyathelo okuthumela ngaphandle.

Amava eProjekthi

I-Womic Steel inikezele ngezixhobo kwiiprojekthi ezininzi ezidumileyo kwihlabathi liphela, kuquka:

1. Iiprojekthi zoBunjineli boLwandle: Zibonelele ngeepleyiti zentsimbi ezinamandla aphezulu zokwakha amaqonga aselunxwemeni kunye neenqanawa zeenqanawa.

2. Uphuhliso lweZiseko zoPhuhliso:Kubonelelwe ngentsimbi yokwakha iibhulorho, iitonela, kunye nezinye iziseko ezibalulekileyo.

3. Izicelo zemizi-mveliso:Kuthunyelwe izisombululo zentsimbi ezenzelwe wena zezityalo zokwenza imveliso, iindawo zokucoca, kunye nezikhululo zamandla.

4. Amandla Avuselelekayo:Sixhase ukwakhiwa kweenqaba ze-wind turbine kunye nezinye iiprojekthi zamandla avuselelekayo ngeemveliso zethu zentsimbi ezinamandla aphezulu.

Iingenelo zeMveliso, Uhlolo, kunye neLogistics zeWomic Steel

1. Izixhobo zeMveliso eziPhambili

I-Womic Steel ixhotyiswe ngezixhobo zokwenza izinto zanamhlanje ezivumela ulawulo oluchanekileyo lwemichiza kunye neempawu zoomatshini. Imigca yethu yemveliso inako ukuvelisa uluhlu olubanzi lweemveliso zentsimbi, kuquka iipleyiti, iipayipi, iibhari, kunye neengcingo, ezinobukhulu kunye nobukhulu obunokulungiselelwa.

2. Ulawulo oluQondileyo loMgangatho

Umgangatho uphambili kwimisebenzi yeWomic Steel. Silandela amanyathelo angqongqo okulawula umgangatho ukuqinisekisa ukuba iimveliso zethu zihlangabezana nemigangatho ephezulu. Inkqubo yethu yokuqinisekisa umgangatho ibandakanya:

Uhlalutyo lweeKhemikhali: Ukuqinisekisa ukwakheka kweekhemikhali kwezinto ezikrwada kunye neemveliso ezigqityiweyo.

Uvavanyo lweMishini: Ukwenza uvavanyo lokuxinana, impembelelo, kunye nobunzima ukuqinisekisa ukuba iimpawu zemishini ziyahlangabezana neemfuno.

Uvavanyo Olungonakalisiyo: Ukusebenzisa uvavanyo lwe-ultrasound kunye ne-radiographic ukufumanisa iziphene zangaphakathi nokuqinisekisa ukuthembeka kwesakhiwo.

3. Iinkonzo zoHlolo oluBanzi

I-Womic Steel inikezela ngeenkonzo zokuhlola ezipheleleyo ukuqinisekisa umgangatho wemveliso. Iinkonzo zethu zokuhlola ziquka:

Uhlolo lweQela lesithathu: Sibonelela ngeenkonzo zohlolo lweqela lesithathu ukuze siqinisekise umgangatho wemveliso ngokuzimeleyo.

Uhlolo lwangaphakathi: Iqela lethu lohlolo lwangaphakathi lenza uhlolo olucokisekileyo kuzo zonke izigaba zenkqubo yemveliso ukuqinisekisa ukuthotyelwa kwemigangatho yoshishino.

4. Uthutho oluSebenzayo kunye noLothutho

I-Womic Steel inenethiwekhi eqinileyo yezothutho eqinisekisa ukuhanjiswa kweemveliso ngexesha elifanelekileyo kwihlabathi liphela. Iingenelo zethu zothutho kunye nezothutho ziquka:

Indawo Ecwangcisiweyo: Ukuba kufutshane namazibuko amakhulu kunye neendawo zokuthutha kwenza kube lula ukuthunyelwa nokuphathwa kakuhle kwezithuthi.

Ukupakishwa Okukhuselekileyo: Iimveliso zipakishwa ngokukhuselekileyo ukuze zingamonakalisi ngexesha lokuhamba. Sinikezela ngezisombululo zokupakisha ezenzelwe wena ukuhlangabezana neemfuno ezithile zabathengi.

Ukufikelela kwiHlabathi: Inethiwekhi yethu enkulu yezothutho isenza sikwazi ukuhambisa iimveliso kubathengi kwihlabathi liphela, siqinisekisa ukunikezelwa ngexesha elifanelekileyo nangokuthembekileyo.

Ixesha leposi: Julayi-27-2024