IiFlanges ze-ASTM A182 ze-Alloy-Steel eziQokelelweyo okanye eziRholiweyo, izixhobo eziQokelelweyo, kunye neeValve

I-ASTM A182 yinkcazo ebalulekileyo yeeflanges zentsimbi ezixonxiweyo okanye ezigoqiweyo, izixhobo ezixonxiweyo, kunye neevalvu ezenzelwe ukusetyenziswa kwiindawo ezinobushushu obuphezulu, ezinoxinzelelo oluphezulu. Lo mgangatho ubonelela ngezikhokelo zokwakheka kweekhemikhali, iimpawu zoomatshini, iindlela zokuvavanya, kunye nezinye izinto ezibalulekileyo eziqinisekisa ukuqina nokuthembeka kwezi zinto kwizicelo ezibalulekileyo.

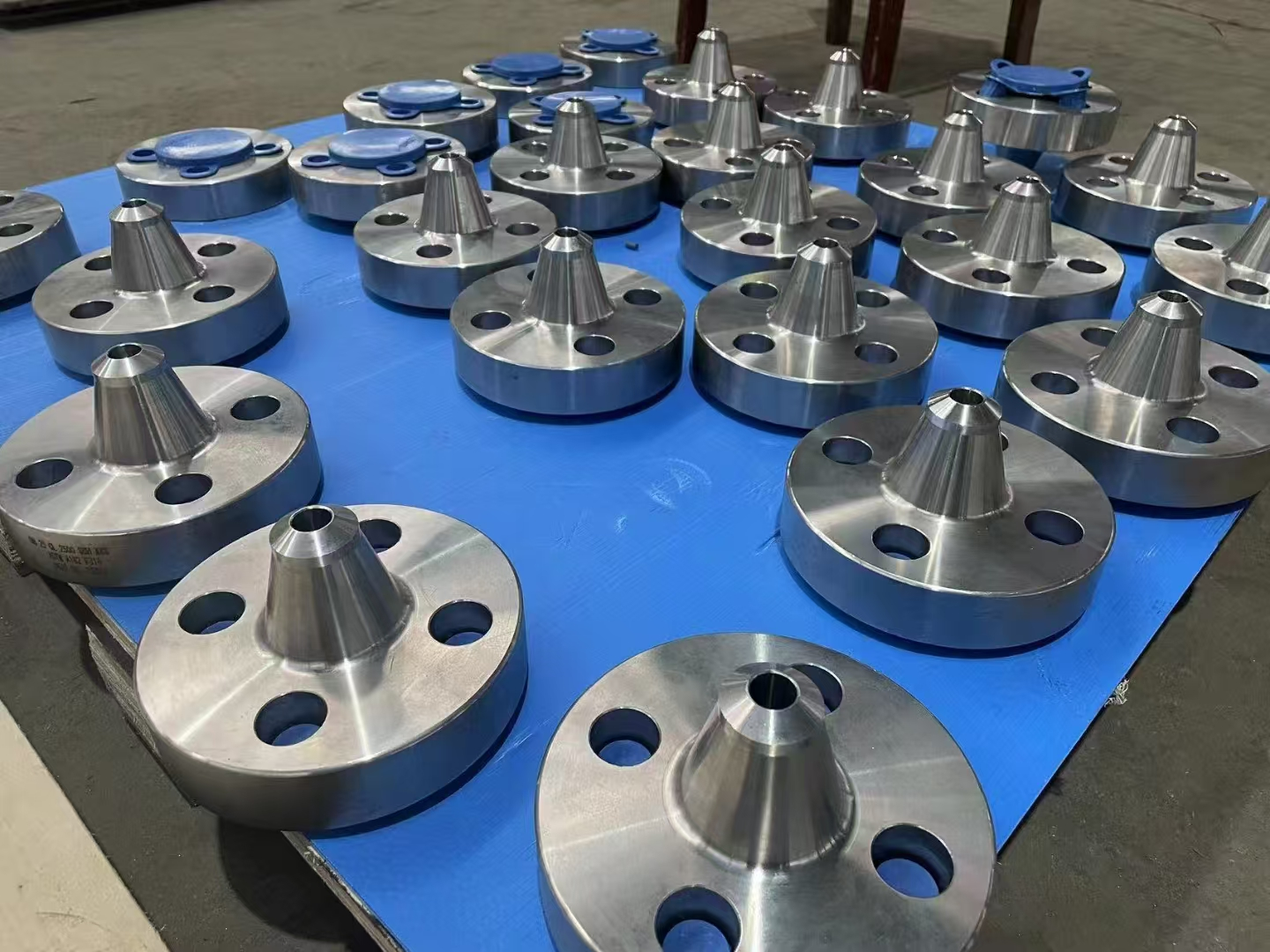

Apha eWomic Steel, senza uluhlu olubanzi lweemveliso ezihambelana nomgangatho we-ASTM A182, ezibonelela ngomgangatho ophezulu kunye nokuchaneka. Kweli nqaku, siza kuhlola izinto ezibalulekileyo zalo mgangatho kwaye sibonise amandla emveliso eWomic Steel kunye neenzuzo zokukhetha thina njengomthengisi wakho.

Iintlobo zeeMveliso eziGutyungelwe yi-ASTM A182

I-ASTM A182 igubungela izinto ezahlukeneyo zentsimbi ezibunjiweyo okanye ezisongiweyo, kuquka:

1. Iiflanges – Ezi zisetyenziselwa ukuqhagamshela imibhobho, iivalvu, iimpompo, kunye nezinye izixhobo kwinkqubo yemibhobho.

2. Izixhobo ezifakelweyo – Ezi ziquka iingqiniba, ii-tee, ii-reducers, ii-caps, kunye nee-unions ezisetyenziswa kwiinkqubo zoxinzelelo oluphezulu.

3. Iivalvu – Zenzelwe ukulawula ukuhamba kolwelo kwiindawo ezinobushushu obuphezulu.

4. Ezinye iimveliso ezibunjiweyo okanye eziqengqelweyo – Ezi ziquka iivalvu kunye nezixhobo ezisetyenziswa kumphunga, igesi, kunye nezinye iinkqubo zoxinzelelo oluphezulu.

KwiWomic Steel, sivelisa ezi zinto ngobukhulu obahlukeneyo, izixhobo, kunye noqwalaselo, ukuqinisekisa ukuba ziyahlangabezana neemfuno zakho ezithile zesicelo.

Izixhobo kunye noKwakhiwa kweeKhemikhali

Umgangatho we-ASTM A182 uchaza amanqanaba ahlukeneyo ezinto, kubandakanya intsimbi yekhabhoni, intsimbi e-alloy ephantsi, kunye nentsimbi engagqwaliyo, nganye ineemfuno ezahlukeneyo zokwakheka kweekhemikhali. Nazi ezinye zezixhobo eziphambili ezigutyungelwe yi-ASTM A182:

1. Ibanga F1 - Intsimbi yekhabhoni enomdibaniso ovumela ukuba isebenze kumaqondo obushushu aphakathi.

2. Udidi F5, F9, F11, F22 – Iintsimbi ze-alloy eziphantsi ezenzelwe ukumelana namaqondo obushushu aphezulu kunye noxinzelelo.

3. Ibanga F304, F304L, F316, F316L – Iintsimbi ezingenasici zaseAustenitic, ezisetyenziswa kakhulu ngenxa yokumelana nokugqwala kwazo kwiindawo ezahlukeneyo zokucubungula iikhemikhali.

Kwinqanaba ngalinye, ulwakhiwo lweekhemikhali lulawulwa ngononophelo ukuze luhlangabezane neemfuno ezingqongqo ze-ASTM. Apha ngezantsi kukho iinkcukacha zolwakhiwo lweekhemikhali lwesixhobo ngasinye kunye neempawu zoomatshini.

Ukwakhiwa kweeKhemikhali kunye neePropati zoMatshini

1. Ibanga F1 - Intsimbi yekhabhoni

Ukwenziwa kweekhemikhali:

Ikhabhoni (C): 0.30-0.60%

IManganese (Mn): 0.60-0.90%

I-Silicon (Si): 0.10-0.35%

I-Sulfur (S): ≤ 0.05%

I-Phosphorus (P): ≤ 0.035%

Iipropati zoomatshini:

Amandla okuThamba (MPa): ≥ 485

Amandla Okuvelisa (i-MPa): ≥ 205

Ukwandiswa (%): ≥ 20

2. Ibanga le-F5 - Intsimbi ye-Alloy ephantsi

Ukwenziwa kweekhemikhali:

Ikhabhoni (C): 0.10-0.15%

IManganese (Mn): 0.50-0.80%

I-Chromium (Cr): 4.50-5.50%

I-Molybdenum (Mo): 0.90-1.10%

I-Sulfur (S): ≤ 0.03%

I-Phosphorus (P): ≤ 0.03%

Iipropati zoomatshini:

Amandla okuThamba (MPa): ≥ 655

Amandla Okuvelisa (i-MPa): ≥ 345

Ukwandiswa (%): ≥ 20

3. Ibanga F304 - Intsimbi Engagqwaliyo yaseAustenitic

Ukwenziwa kweekhemikhali:

Ikhabhoni (C): ≤ 0.08%

IManganese (Mn): 2.00-2.50%

I-Chromium (Cr): 18.00-20.00%

I-Nickel (Ni): 8.00-10.50%

I-Sulfur (S): ≤ 0.03%

I-Phosphorus (P): ≤ 0.045%

Iipropati zoomatshini:

Amandla okuThamba (MPa): ≥ 515

Amandla Okuvelisa (i-MPa): ≥ 205

Ukwandiswa (%): ≥ 40

4. Ibanga le-F316 - Intsimbi Engagqwaliyo yase-Austenitic (Engamelaniyo Nokugqwala)

Ukwenziwa kweekhemikhali:

Ikhabhoni (C): ≤ 0.08%

IManganese (Mn): 2.00-3.00%

I-Chromium (Cr): 16.00-18.00%

I-Nickel (Ni): 10.00-14.00%

I-Molybdenum (Mo): 2.00-3.00%

I-Sulfur (S): ≤ 0.03%

I-Phosphorus (P): ≤ 0.045%

Iipropati zoomatshini:

Amandla okuThamba (MPa): ≥ 515

Amandla Okuvelisa (i-MPa): ≥ 205

Ukwandiswa (%): ≥ 40

Iipropati zoomatshini kunye neemfuno zempembelelo

Iimpawu zoomatshini ezifana namandla okutsalwa, amandla okukhupha, kunye nokwandiswa zibalulekile ekuqinisekiseni ukuba izinto ezifakelweyo zisebenza ngokuthembekileyo phantsi koxinzelelo. I-ASTM A182 ichaza ezi mpawu zodidi ngalunye lwezinto, kunye neemfuno ziyahluka ngokusekwe kwiimeko zokusetyenziswa.

Uvavanyo lwempembelelolelinye icandelo elibalulekileyo lomgangatho, ukuqinisekisa ukuba iindawo ezibunjiweyo ziyakwazi ukumelana notshintsho olukhawulezileyo kubushushu okanye impembelelo. Umzekelo, umgangatho ungafuna uvavanyo lweCharpy V-notch ukuqinisekisa ukuqina kwiimeko zobushushu obuphantsi.

Iinkqubo zeMveliso kunye neemfuno zoNyango loBushushu

I-Womic Steel ilandela iinkqubo zemveliso ezingqongqo ukuqinisekisa ukuba zonke iimveliso ze-ASTM A182 ziyahlangabezana nemigangatho ephezulu yomgangatho. Oku kuquka:

Ukwakha nokuqengqeleka – Oomatshini bethu banamhlanje baqinisekisa ukuba inxalenye nganye yenziwe okanye iqengqelwe ngokwemilinganiselo echanekileyo kunye nokunyamezelana.

Unyango lobushushu – Unyango lobushushu lubalulekile ekufezekiseni iimpawu zoomatshini ezifunekayo. I-ASTM A182 ifuna imijikelo ethile yonyango lobushushu ngokuxhomekeke kudidi lwezinto, njengokuqhoboshela, ukucima, kunye nokufudumala ukuphucula ukuqina kunye namandla.

Ukuwelda – Sinikezela ngezisombululo zokuwelda ezenziwe ngokwezifiso kwiimveliso ze-ASTM A182, siqinisekisa uqhagamshelo oluthembekileyo nolungavuziyo. Iinkqubo zokuwelda zilawulwa ngononophelo ukuqinisekisa ukuba iindawo eziweldayo zidibana okanye zigqitha amandla ezinto ezisisiseko.

Ukuhlolwa noVavanyo

Senza yonke intoukuhlolwa nokuvavanywaukuqinisekisa ukuba zonke iimveliso ziyahlangabezana nomgangatho we-ASTM A182. Oku kuquka:

Uhlolo olubonakalayo – Ngeziphene okanye ukungapheleli komphezulu.

Uvavanyo Olungonakalisiyo (NDT) – Kubandakanya uvavanyo lwe-ultrasound kunye nokuhlolwa kwe-radiographic ukuze kufunyanwe iziphene zangaphakathi.

Uvavanyo lweMishini – Amandla okutsalwa, amandla okukhupha, kunye novavanyo lwempembelelo ukuqinisekisa ukusebenza kwesixhobo phantsi koxinzelelo.

Uhlalutyo lweeKhemikhali – Ukuqinisekisa ukuba ukwakheka kweekhemikhali kuyahambelana neemfuno zomgangatho.

Zonke iimveliso zethu zilandela iinkqubo ezingqongqo zolawulo lomgangatho, kwaye sinikezela ngeziqinisekiso ezineenkcukacha zokuthobela yonke iodolo.

Iinkcukacha zeMveliso kunye noLuhlu loBukhulu

At Intsimbi yeWomic, sinikezela ngeendidi ezahlukeneyo zeemveliso ze-ASTM A182 ngobukhulu obahlukeneyo kunye neenkcukacha.uluhlu lobungakananiibandakanya:

Iiflanges: Ukusuka kwi-1/2" ukuya kwi-60" ububanzi.

Izixhobo ezifakelweyo: Ukusuka kwi-1/2" ukuya kwi-48" ububanzi.

Iivalvu: Ubungakanani obulungiselelwe wena ukuze buhambelane neemfuno zenkqubo yakho.

Iimveliso zethu ziyafumaneka ngemilinganiselo eyahlukeneyo yoxinzelelo kunye nezixhobo, ukuqinisekisa ukuba sinokuhlangabezana neemfuno ezithile zeprojekthi yakho.

Iingenelo zokuPakisha, ukuThumela, kunye nokuThutha

Siyaqonda ukubaluleka kokuhanjiswa kwempahla ngexesha elifanelekileyo nangokukhuselekileyo. Izibonelelo zeWomic Steelukupakishwa okwenziwe ngokwezifisoekhusela ukuthembeka kweemveliso ngexesha lokuhamba. Nokuba kungokuthunyelwa ngeekhonteyina okanye izisombululo ezikhethekileyo zokuthutha, siyaqinisekisa ukuba iodolo yakho ifika ngexesha kwaye ikwimeko entle.

Zethuubuchule bezothuthokunye nobudlelwane obuthe ngqo neenkampani zokuthumela ngenqanawa kusenza sikwazi ukubonelela ngamaxabiso akhuphisanayo kunye nezisombululo zokuthumela ngenqanawa eziguquguqukayo.

Ukwenziwa ngokwezifiso kunye neeNkonzo ezongezelelweyo

Ukongeza kuluhlu lwethu olubanzi lweemveliso ezisemgangathweni, iWomic Steel inikezelaukwenziwa ngokwezifisongeemfuno ezizodwa. Singatshintsha ubukhulu, izixhobo, kunye nokugqitywa ukuze kuhambelane nesicelo sakho esithile.

Iinkonzo zokucubungulaziquka:

Umatshini – Ukuze kwenziwe utshintsho oluchanekileyo ukuze luhambelane neemfuno zakho.

Ukuwelda – Ukudibanisa okanye ukufakelwa kweflange okwenziwe ngokwezifiso.

Iinkonzo zokugquma kunye nokulwa nokugqwala – Ukubonelela ngokhuseleko oluhlala ixesha elide ngokusekelwe kwiimfuno zakho zokusingqongileyo.

Kutheni Ukhetha Intsimbi Yesifazane?

Umthamo weMveliso: Sinezixhobo zokuvelisa ezikumgangatho ophezulu ezinezakhono eziphezulu zokuvelisa.

Ubuchule boBugcisaIqela lethu liquka iinjineli kunye neengcali ezinobuchule obuphezulu ezizinikele ekuveliseni iimveliso ezikumgangatho ophezulu.

Inzuzo yeCandelo loNikezelo: Sinobudlelwane obuqinileyo nababoneleli bezinto eziluhlaza, siqinisekisa ukuhanjiswa ngexesha elifanelekileyo kunye neenzuzo zeendleko.

Iinketho zokwenza ngokwezifiso: Sinikezela ngezisombululo eziguquguqukayo ukuhlangabezana neemfuno ezithile zeprojekthi, kubandakanya ukuwelda, umatshini wokulungisa, kunye nokufaka ipeyinti.

Isiphelo

IUmgangatho we-ASTM A182iqinisekisa ukuthembeka nokusebenza kweemveliso zentsimbi ezibunjiweyo neziqengqiweyo kwizicelo ezibalulekileyo. I-Womic Steel liqabane lakho elithembekileyo leemveliso ezikumgangatho ophezulu ezenziwe ngolu hlobo, linikezela ngenkxaso epheleleyo ukusuka kwiinkcukacha zobugcisa ukuya kwi-logistics. Nokuba ufuna ubungakanani obulungiselelwe wena, ukuwelda, okanye ii-coating ezikhethekileyo, sinikezela ngezisombululo ezenzelwe wena ukuhlangabezana neemfuno zakho, siqinisekisa ukusebenza okuphezulu kunye nokuthembeka kokuhanjiswa.

Iwebhusayithi: www.womicsteel.com

I-imeyile: sales@womicsteel.com

Ucingo/WhatsApp/WeChat: Victor: +86-15575100681 okanye uJack: +86-18390957568

Ixesha leposi: Epreli-21-2025