1.Isishwankathelo seMveliso

I-Womic Steel igxile ekuveliseni iityhubhu zobhedu ezikumgangatho ophezulu ezihambelana nomgangatho we-EN 1057. Ezi tyhubhu zenziwe ngezinto ze-Cu-DHP (CW024A), ziqinisekisa ubunyulu obugqwesileyo kunye nokusebenza kakuhle kwezixhobo zokufaka amanzi, ukusasazwa kwegesi, ukufudumeza, kunye nokupholisa. Ngomxholo omncinci wekopolo nesilivere oyi-99.9% kunye noluhlu lwe-phosphorus olulawulwayo oluphakathi kwe-0.015% kunye ne-0.040%, iityhubhu zethu zobhedu zibonisa ukumelana nokugqwala okugqwesileyo, ukuqina, kunye nokulula kokufakwa.

Iityhubhu zobhedu ze-EN 1057 zenzelwe ukusetyenziswa kwiindawo zasekhaya nezemizi-mveliso, zibonelela ngokusebenza okuthembekileyo kwiinkqubo zamanzi okusela, ukufudumeza okuphakathi, ukukhenkceza, kunye nemibhobho yegesi yezonyango. Zenziwe ngokwemigangatho engqongqo yomgangatho, ezi tyhubhu zibonelela ngeempawu zoomatshini eziphezulu kunye nokuthembeka kwenkonzo yexesha elide.

2.EN 1057 Uluhlu lweMveliso yeMibhobho yobhedu

●Ububanzi Bangaphandle (OD):6 mm ukuya kwi-267 mm

●Ubukhulu bodonga (WT):0.3mm ukuya kwi20mm

●Ubude:Ubude obuqhelekileyo obuyi-3m, 5m, okanye 6m; ubude obulungiselelwe wena bufumaneka xa uceliwe

●Iityhubhu ezibhityiweyo:Ifumaneka kwiikhoyili ezingama-25m okanye ezingama-50m ukuze ifakwe ngokuguquguqukayo

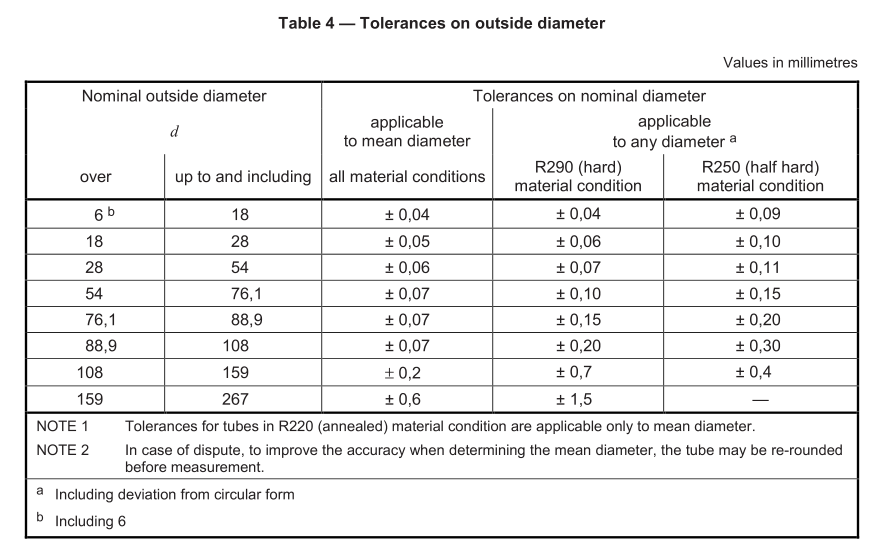

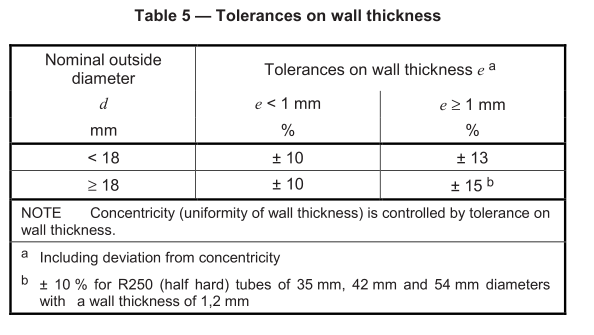

3.I-EN 1057 Ukunyamezela kweMibhobho yobhedu

I-Womic Steel iqinisekisa ukuchaneka okuchanekileyo kobukhulu kunye nokunyamezela okulandelayo:

4.EN 1057 Iityhubhu zeCopper Composition yeekhemikhali

Iityhubhu zethu zobhedu zenziwe ngezinto zeCu-DHP (CW024A) eziqulathe oku kulandelayo:

Ulwakhiwo kufuneka luhambelane neemfuno ezilandelayo:

I-Cu + Ag: ubuncinci be-99,90 %;

0,015 %≤P≤0,040 %.

Olu didi lwekopolo lubizwa ngokuba yiCu-DHP okanye iCW024A.

Olu lwakhiwo luqinisekisa ukumelana nokugqwala okugqwesileyo, ukuhanjiswa kobushushu obuphezulu kunye nombane, kunye nokusebenza kakuhle.

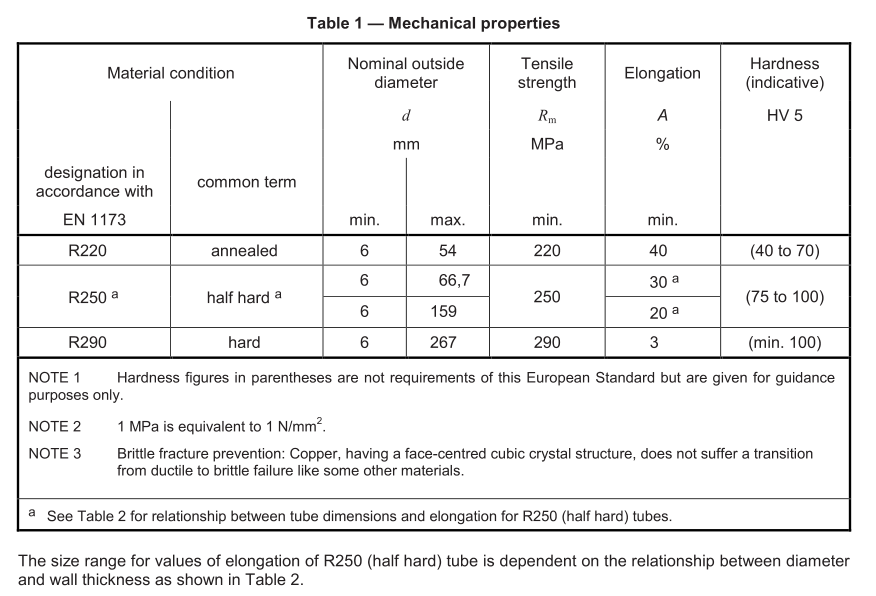

5.Iipropati zoomatshini ze-EN 1057 zeCopper Tubes

Iimpawu zoomatshini zeetyhubhu zethu zobhedu ze-EN 1057 zixhomekeke kwimeko yokuhanjiswa:

6.Iimeko zokuhanjiswa kweetyhubhu zeCopper ze-EN 1057

I-Womic Steel inika iityhubhu zobhedu ze-EN 1057 kwezi temperature zilandelayo:

●R220 (Efakwe kwi-Anneal): Iguquguquka kakhulu, ifanelekile ukugoba nokwenza

●R250 (Half-Hard): Amandla aphakathi, ulungelelwano oluhle lokuguquguquka kunye nokuqina

●R290 (Eqinileyo): Amandla aphezulu, afanele ukusetyenziswa ngokuthe tye kwaye angabi nagobeko kangako

7.Inkqubo yokwenziwa kweetyhubhu zekopolo ze-EN 1057

Inkqubo yethu yemveliso ephucukileyo iqinisekisa imigangatho ephezulu yomgangatho:

1. Ukulungiswa kweCasting kunye neBillet: Ubhedu olucocekileyo kakhulu luyanyibilikiswa luze luphoswe kwiibillets.

2. Ukukhupha kunye nokubhoboza: Iibhilethi zikhutshwa zibe yityhubhu kwaye zigqojozwe ngokwemilinganiselo efunekayo.

3. Umzobo obandayo: Iityhubhu zitsalwa ngeedayi ukuze kufezekiswe ubungakanani obuchanekileyo.

4. Ukufakela: Unyango lobushushu lusetyenziswa ukufezekisa iimpawu zoomatshini ezifunekayo.

5. Ukulungisa nokusika: Iityhubhu ziyalungiswa kwaye zinqunyulwe ngobude obufunekayo.

6. Uhlolo noVavanyo: Ukuhlolwa komgangatho okungqongqo kuqinisekisa ukuthotyelwa kwemigangatho ye-EN 1057.

8.Uvavanyo kunye nokuhlolwa

I-Womic Steel iqinisekisa ulawulo olupheleleyo lomgangatho ngovavanyo olupheleleyo, kuquka:

●Uhlalutyo lweeKhemikhali/lweSpectrographic: Ukuqinisekiswa kokwakheka kwezinto kusetyenziswa iindlela zeekhemikhali okanye zespectroscopic.

●Uvavanyo lokuThatha: Uvavanyo lwamandla okuThatha kunye neempawu zobude (EN 10002-1).

●Uvavanyo loBulukhuni: Ukulinganiswa kobulukhuni bezinto ngendlela yeVickers (EN ISO 6507-1).

●Uvavanyo loMxholo weKhabhoni: Ukuqinisekiswa kobungakanani bepesenti yekhabhoni kusetyenziswa indlela yesalathiso ye-EN 723.

●Uvavanyo lweFilimu yeKhabhoni: Ukufumanisa nokuvavanya ubukho befilimu yekhabhoni (Isihlomelo B).

●Uvavanyo lokugoba: Uvavanyo lokugoba phantsi

●Uvavanyo Lokwandisa Ukuntywila: Ukwandiswa kwesiphelo setyhubhu ngama-30% nge45°i-mandrel ekhonkxiweyo ukuqinisekisa ukuguquguquka kwayo (EN ISO 8493).

●Uvavanyo lweFlanging: Ukuqinisekiswa kokwakheka kweflange (ubuncinci bonyuko lwe-30% kububanzi betyhubhu) kusetyenziswa isixhobo esine-1 mm yekona radius (EN ISO 8494).

●Uvavanyo lweNkululeko kwiziphene:

●Uvavanyo lwangoku lwe-Eddy (ECT): Ukufunyanwa kweziphene zomphezulu/zomphezulu ongaphantsi komhlaba (EN 1971 kunye neSihlomelo C.1).

●Uvavanyo lweHydrostatic: Ukuqinisekiswa kokumelana noxinzelelo ngokusebenzisa uxinzelelo lwamanzi (Isihlomelo C.2).

●Uvavanyo lwe-Pneumatic: Ukufunyanwa kokuvuza kusetyenziswa uxinzelelo lomoya/igesi (Isihlomelo C.3).

●Qaphela: Imiyalelo yovavanyo lohlobo lokuqala yi-ECT; ezinye iindlela zikhethwa ngumenzi.

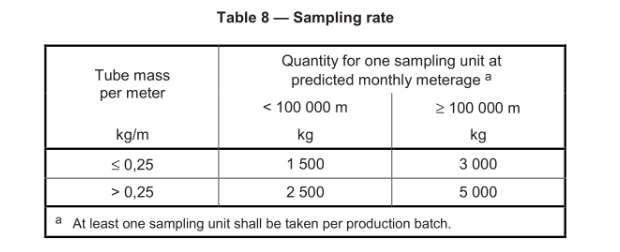

9. Isampuli:

Ngenjongo yokuqinisekisa umgangatho ngexesha lokuveliswa, inani leeyunithi zokuthatha iisampulu eziza kuthathwa ngokungacwangciswanga kufuneka libengokuhambelana neTheyibhile 8.

La mazinga okuthatha iisampulu aya kusebenza xa kuvavanywa ulawulo olunemilinganiselo; ulawulo lwezinye iimpawu eziyimfuneko luya kwenziwa kwiyunithi nganye yesibini yokuthatha iisampulu.

Iziphumo zingasetyenziswa kuhlalutyo olwenziwe kwinqanaba langaphambili lokwenziwa kwemveliso, umz. kwinqanaba lokwenziwa kwemveliso okanye i-billets, ukuba ubunikazi bemveliso bugciniwe kwaye ukuba inkqubo yolawulo lomgangatho yomenzi ihambelana neemfuno ezifanelekileyo ze-EN lSO 9001.

10.Ukupakisha

Ukuqinisekisa ukuphathwa nokuthuthwa ngokukhuselekileyo, iityhubhu zethu zobhedu zipakishwe ngolu hlobo lulandelayo:

●Isigqubuthelo sokungafaki i-oxidation: Umaleko okhuselayo ufakwa kumphezulu weetyhubhu zobhedu ukuthintela i-oxidation kunye nokutshintsha kombala ngexesha lokugcina kunye nokuthuthwa.

●Ii-End Caps: Ii-end caps zeplastiki okanye zesinyithi ezimelana nokugqwala zifakelwe kwimiphetho yeetyhubhu ukuthintela ungcoliseko kunye nomonakalo woomatshini.

●Ukubopha: Iityhubhu zihlanganiswe ngokweemfuno kwaye zibotshelelwe ngokukhuselekileyo ngeentambo zeplastiki ezinamandla aphezulu ukunciphisa intshukumo ngexesha lokuhamba.

●Iibhokisi zomthi: Iityhubhu ezihlanganisiweyo zifakwa kwiibhokisi zomthi ezingangenisi manzi. Iibhokisi zigqunywe ngefoam engangeni manzi okanye izinto zokucoca ulwelo ukuthintela umonakalo womswakama kunye nokuthobela imigangatho ye-ISPM 15 yamazwe ngamazwe ye-phytosanitary.

●Ukuvala Okuqinisiweyo: Iikreyiti zivalwa ngeebhendi zentsimbi okanye izibophelelo ezinzima. Ukusonga okuncinci okukhethwayo kuyafumaneka ukuze kuthintelwe imozulu eyongezelelweyo.

●Ukubhala iilebheli: Ibhokisi nganye ibhalwe ngobubanzi bangaphandle betyhubhu (OD), ubukhulu bodonga (WT), ubude, ubushushu (umz., uthambile, uqinileyo), inombolo yebhetshi yemveliso, kunye nomhla ukuqinisekisa ukulandeleka ngokupheleleyo.

11.Ezothutho kunye neeLogistics

I-Womic Steel iqinisekisa ukuhanjiswa kweetyhubhu zobhedu ze-EN 1057 ngexesha elifanelekileyo nangokukhuselekileyo:

●Ukuthunyelwa Kweenqanawa: Ukuthunyelwa kwempahla kwihlabathi liphela kwiikhonteyina ezikhuselekileyo

●Uthutho lukaloliwe okanye lwendlela: Ukuhanjiswa okuthembekileyo kwasekhaya nakwengingqi

●Uthutho oluLawulwa yiMozulu: Lufumaneka kwii-applications ezinobuzaza

●Amaxwebhu apheleleyo: Amaxwebhu okuthumela kunye ne-inshurensi ziyabonelelwa

●Ubhedu oluQinisekileyo oluPhezulu: Ukuqina okungaqhelekanga kunye nokumelana nokugqwala

● Ukuvelisa ngokuchanekileyo: Ukunyamezelana okuqinileyo okunobukhulu bokusebenza okuthembekileyo

●Izisombululo ezenziwe ngokwezifiso: Ubude obulungiselelwe wena, i-temperature, kunye neengubo ziyafumaneka

●Uvavanyo Olupheleleyo: Ukuqinisekisa ukuthotyelwa kwemigangatho yamazwe ngamazwe

●Ukuhanjiswa kweHlabathi: Ukuhanjiswa kwehlabathi okuthembekileyo nokufike ngexesha elifanelekileyo

12.Iingenelo zokukhetha intsimbi yeWomic

- ●Ubhedu oluQinisekileyo oluPhezulu: Ukuqina okungaqhelekanga kunye nokumelana nokugqwala

- ● Ukuvelisa ngokuchanekileyo: Ukunyamezelana okuqinileyo okunobukhulu bokusebenza okuthembekileyo

- ●Izisombululo ezenziwe ngokwezifiso: Ubude obulungiselelwe wena, i-temperature, kunye neengubo ziyafumaneka

- ●Uvavanyo Olupheleleyo: Ukuqinisekisa ukuthotyelwa kwemigangatho yamazwe ngamazwe

- ●Ukuhanjiswa kweHlabathi: Ukuhanjiswa kwehlabathi okuthembekileyo nokufike ngexesha elifanelekileyo

13.Izicelo

Iityhubhu zobhedu ze-EN 1057 zisetyenziswa kakhulu kwezi:

- Iinkqubo zoMbhobho: Ukusasazwa kwamanzi okusela okukhuselekileyo nokuthembekileyo

- Ukusasazwa kweGesi: Ilungele ukusetyenziswa kwegesi yendalo kunye neLPG

- Iinkqubo zokufudumeza: Ukusebenza kakuhle kwiiradiator kunye nokufudumeza phantsi komgangatho

- Ifriji kunye ne-Air Conditioning: Ubushushu obuphezulu kwiinkqubo zokupholisa

- Iipayipi zeGesi zonyango: Zithembeke kwizibhedlele ngeoksijini kunye neegesi zonyango

Isiphelo

Iityhubhu zeCopper ze-EN 1057 zeWomic Steel zibonelela ngomgangatho ophezulu, amandla, kunye nokuthembeka kwimibhobho, igesi, kunye nokusetyenziswa kwemizi-mveliso. Ukuzibophelela kwethu ekwenzeni ngokuchanekileyo, uvavanyo oluqinileyo, kunye nezisombululo ezijolise kubathengi kusenza sibe liqabane elithembekileyo kushishino.

Khetha iWomic Steel Group njengeqabane lakho elithembekileyo lomgangatho ophezuluIityhubhu zeCopper&Izinto ezifakelwayo kunye nokusebenza kakuhle kokuhanjiswa. Wamkelekile Umbuzo!

Iwebhusayithi: www.womicsteel.com

I-imeyile: sales@womicsteel.com

Ucingo/WhatsApp/WeChat: Victor: +86-15575100681 okanye uJack: +86-18390957568

Ixesha leposi: Matshi-10-2025