Yintoni iflange?

I-Flange ngamafutshane, ligama nje eliqhelekileyo, lidla ngokubhekisa kumzimba wesinyithi ofana nediski ukuvula imingxunya embalwa esisigxina, esetyenziselwa ukudibanisa ezinye izinto, olu hlobo lwento lusetyenziswa kakhulu koomatshini, ngoko ke lubonakala lungaqhelekanga kancinci, logama nje lusaziwa njenge-flange, igama lalo livela kwi-flange yesiNgesi. Ukuze umbhobho kunye nokudibana kombhobho kwamacandelo, aqhagamshelwe esiphelweni sombhobho, i-flange ibe ne-aperture, izikrufu zokwenza ii-flange ezimbini. Ziqhagamshelwe ngokuqinileyo, phakathi kwe-flange nge-gasket seal.

I-Flange yinxalenye efana nediski, eyona ixhaphakileyo kubunjineli bemibhobho, i-flange isetyenziswa ngababini.

Ngokuphathelele iintlobo zoqhagamshelo lweflange, kukho izinto ezintathu:

- Iiflange zepayipi

- I-Gasket

- Uqhagamshelo lweBolt

Kwiimeko ezininzi, kukho into ethile ye-gasket kunye ne-bolt efunyenweyo eyenziwe ngezinto ezifanayo nenxalenye ye-flange yombhobho. Ezona flange zixhaphakileyo zii-flange zentsimbi engagqwaliyo. Kwelinye icala, ii-flange ziyafumaneka kwiindidi ezahlukeneyo zezixhobo ukuze zihambelane neemfuno zendawo. Ezinye zezona zinto zixhaphakileyo ze-flange yi-monel, i-inconel, kunye ne-chrome molybdenum, kuxhomekeke kwiimfuno zendawo. Ukhetho olufanelekileyo lwezixhobo kufuneka luxhomekeke kuhlobo lwenkqubo ofuna ukuyisebenzisa kuyo i-flange eneemfuno ezithile.

Iintlobo ezi-7 eziqhelekileyo zeeFlanges

Kukho iintlobo ngeentlobo zeeflanges ezinokukhethwa ngokweemfuno zendawo. Ukuze kuhambelane noyilo lweflanges efanelekileyo, kufuneka kuqinisekiswe ukusebenza okuthembekileyo kunye nobomi benkonzo ende kwaye ixabiso elifanelekileyo lifanele liqwalaselwe.

1. iflengi eneentambo:

Iiflange ezinemisonto, ezinemisonto kwibhore yeflange, zifakelwe imisonto yangaphandle kwi-fitting. Uqhagamshelo lwemisonto apha lwenzelwe ukuphepha ukuwelda kuzo zonke iimeko. Iqhagamshelwe ikakhulu ngokufanisa imisonto nombhobho oza kufakelwa.

2. Iiflange ze-socket weld

Olu hlobo lweflange ludla ngokusetyenziselwa imibhobho emincinci apho ububanzi bommandla wobushushu obuphantsi kunye noxinzelelo oluphantsi lubonakaliswa luqhagamshelo apho umbhobho ufakwa ngaphakathi kweflange ukuqinisekisa uqhagamshelo nge-fillet weld enye okanye ezininzi. Oku kuthintela imida enxulumene neziphelo ezinemisonto xa kuthelekiswa nezinye iintlobo zeflange ezidibeneyo, ngaloo ndlela kwenza ukufakwa kube lula.

3. Iiflanges zeLap

I-flange ejijekileyo luhlobo lwe-flange olufuna ukuba isiphelo se-stub sidityaniswe kwi-fitting ukuze sisetyenziswe ne-flange exhasayo ukwenza uqhagamshelo olujijekileyo. Olu yilo lwenze le ndlela yathandwa kwiinkqubo ezahlukeneyo apho isithuba somzimba sincinci, okanye apho kufuneka ukuqhaqhwa rhoqo, okanye apho kufuneka ulondolozo oluphezulu.

4. Iiflange ezityibilikayo

Iiflange ezityibilikayo zixhaphake kakhulu kwaye zifumaneka ngobukhulu obahlukeneyo ukuze zilungele iinkqubo ezinezinga eliphezulu lokuhamba kwamanzi kunye neziphumo. Ukudibanisa nje iflange nobubanzi bangaphandle bombhobho kwenza kube lula kakhulu ukuyifaka iqhagamshelo. Ukufakwa kwezi flanges kuyinto yobuchwephesha njengoko kufuna ukuwelda kwe-fillet kumacala omabini ukuze kuqiniswe iflange kumbhobho.

5. Iiflange ezingaboniyo

Olu hlobo lweeflanges lufanelekile kakhulu ekuphelisweni kweenkqubo zemibhobho. Ipleyiti engaboniyo imile njengediski engenanto enokubotshwa ngebholti. Nje ukuba ezi zifakwe kakuhle kwaye zidityaniswe negasket efanelekileyo, ivumela ukutywinwa okuhle kwaye kulula ukuyisusa xa kuyimfuneko.

6. Iiflanges zentamo eziweldiweyo

Iiflange zentamo eziweldiweyo zifana kakhulu neeflange ezisemacaleni, kodwa zifuna ukuwelda kweempundu ukuze zifakelwe. Kwaye ukuthembeka kokusebenza kwale nkqubo kunye nokukwazi kwayo ukugoba amaxesha amaninzi kwaye isetyenziswe kwiinkqubo zoxinzelelo oluphezulu kunye nobushushu obuphezulu kwenza kube lolona khetho luphambili kwiipayipi zenkqubo.

7. Iiflanges ezikhethekileyo

Olu hlobo lweflange lolona luqhelekileyo. Nangona kunjalo, kukho uluhlu olubanzi lweeflange ezongezelelweyo ezikhethekileyo ezikhoyo ukuze zilungele ukusetyenziswa kunye neendawo ezahlukeneyo. Kukho ezinye iindlela ezahlukeneyo ezifana neeflange ze-nipo, iiflange ze-weldo, iiflanges zokwandisa, ii-orifices, ii-long weld necks kunye nee-reducer flanges.

Iintlobo ezi-5 ezikhethekileyo zeeFlanges

1. WeldoFulusu

I-Weldo flange ifana kakhulu ne-Nipo flange kuba iyindibaniselwano yee-butt-welding flanges kunye nee-branch fitting connections. Ii-Weldo flanges zenziwe ngentsimbi enye eqinileyo, endaweni yokuba iindawo nganye nganye zihlanganiswe.

2. I-flange yeNipo

I-Nipoflange ngumbhobho wesebe ojijekileyo kwi-engile ye-90 degrees, yimveliso eyenziwe ngokuhlanganisa ii-flanges ze-butt-welding kunye ne-Nipolet eyenziweyo. Nangona i-Nipo flange ifunyaniswa ukuba yinxalenye enye eqinileyo yentsimbi eyenziweyo, ayiqondwa njengeemveliso ezimbini ezahlukeneyo ezidityaniswe kunye. Ukufakelwa kwe-Nipoflange kubandakanya ukuwelda kwinxalenye ye-Nipolet yesixhobo ukuze kuqhutywe umbhobho kunye nokubopha inxalenye ye-flange kwi-flange yombhobho we-stub ngabasebenzi bepayipi.

Kubalulekile ukwazi ukuba ii-Nipo flanges ziyafumaneka kwiintlobo ngeentlobo zezinto ezifana ne-carbon, ii-carbon steels ezishushu kakhulu neziphantsi, i-stainless steel grades, kunye nee-nickel alloys. Ii-Nipo flanges zenziwa kakhulu ngokwenziwa okuqinisiweyo, okunceda ukuzinika amandla ongezelelweyo oomatshini xa kuthelekiswa ne-Nipo flange eqhelekileyo.

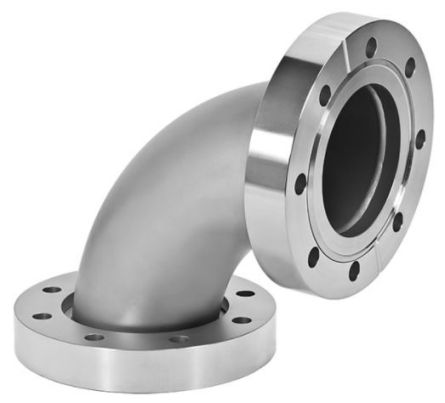

3. I-Elboflange kunye neLatroflange

I-Elboflange yaziwa ngokuba yindibaniselwano yeflange kunye ne-Elbolet ngelixa iLatroflange yaziwa ngokuba yindibaniselwano yeflange kunye neLatrolet. Iiflange ze-elbow zisetyenziselwa ukubopha imibhobho kwi-engile ye-45 degrees.

4. Iiflange zendandatho ezijikelezayo

Ukusetyenziswa kwee-flanges zeringi ezijikelezayo kukwenza kube lula ukulungelelanisa imingxunya yebholthi phakathi kwee-flanges ezimbini ezidibeneyo, nto leyo eluncedo ngakumbi kwiimeko ezininzi, njengokufakelwa kweepayipi ezinkulu ezinobubanzi, iipayipi zasemanzini okanye zaselwandle kunye neendawo ezifanayo. Ezi ntlobo zeeflanges zifanelekile kwiincindi ezifunekayo kwioyile, igesi, ii-hydrocarbons, amanzi, iikhemikhali kunye nezinye izicelo ze-petrochemical kunye nolawulo lwamanzi.

Kwimeko yeepayipi ezinkulu ezinobubanzi, umbhobho ufakwe iflange eqhelekileyo ye-butt weld kwelinye icala kunye neflange ejikelezayo kwelinye. Oku kusebenza ngokujikeleza nje iflange ejikelezayo kumbhobho ukuze umqhubi afikelele ekulungelelanisweni okufanelekileyo kwemingxuma yebholithi ngendlela elula kakhulu nekhawulezayo.

Eminye yemigangatho ephambili yeeflanges zeringi ezijikelezayo yi-ASME okanye i-ANSI, i-DIN, i-BS, i-EN, i-ISO, kunye neminye. Omnye wemigangatho edumileyo yokusetyenziswa kwe-petrochemical yi-ANSI okanye i-ASME B16.5 okanye i-ASME B16.47. Iiflanges ezijikelezayo ziiflanges ezinokusetyenziswa kuzo zonke iimilo eziqhelekileyo zeflange. Umzekelo, iintamo ze-weld, ii-slip ons, ii-lap joints, ii-socket welds, njl., kuzo zonke iiklasi zezinto, kuluhlu olubanzi lobukhulu ukusuka kwi-3/8" ukuya kwi-60", kunye noxinzelelo oluvela kwi-150 ukuya kwi-2500. Ezi flanges zinokwenziwa ngokulula nge-carbon, i-alloy, kunye neentsimbi ezingenasici.

5. Iiflanges zokwandisa

Iiflanges zokwandisa, zisetyenziselwa ukwandisa ubungakanani bembobo yombhobho ukusuka nakweyiphi na indawo ukuya kwenye ukuze kuqhagamshelwe umbhobho nakwezinye izixhobo zoomatshini ezifana neempompo, iicompressor, kunye neevalvu ezifunyenwe zinobukhulu obahlukeneyo bokungena.

Iiflanges zokwandisa zihlala ziiflanges ezifakwe i-butt-welded ezinemingxuma emikhulu kakhulu kwisiphelo esingafakwanga i-flanged. Zingasetyenziselwa ukongeza ubungakanani obunye okanye obubini okanye ukuya kuthi ga kwi-intshi ezi-4 kwi-running pipe bore. Ezi ntlobo zeeflanges zikhethwa ngaphezu kokudibanisa ii-butt-weld reducers kunye neeflanges ezisemgangathweni kuba zibiza kancinci kwaye zilula. Enye yezona zinto zixhaphakileyo ezisetyenziselwa iiflanges zokwandisa yi-A105 kunye ne-ASTM A182 yentsimbi engagqwaliyo.

Iiflanges zokwandisa zifumaneka ngokwemilinganiselo yoxinzelelo kunye nobukhulu ngokuhambelana ne-ANSI okanye i-ASME B16.5 specifications, ezifumaneka ikakhulu kwi-convex okanye flat (RF okanye FF). Iiflanges zokunciphisa, ezaziwa ngokuba ziiflanges zokunciphisa, zisebenza umsebenzi ochaseneyo xa kuthelekiswa neeflanges zokwandisa, oko kuthetha ukuba zisetyenziselwa ukunciphisa ubungakanani bebhore yombhobho. Ububanzi bebhore yombhobho obalekayo bunokuncipha ngokulula, kodwa kungabi ngaphezu kobukhulu obu-1 okanye obu-2. Ukuba kuzanywa ukunciphisa ngaphaya koku, isisombululo esisekelwe kudibaniso lwee-reducers ezifakwe i-butt kunye neeflanges ezisemgangathweni kufuneka zisetyenziswe.

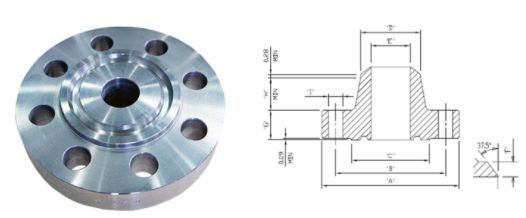

Ubungakanani beFlange kunye nezinto eziqhelekileyo ekufuneka uziqwalasele

Ukongeza kuyilo olusebenzayo lweflange, ubungakanani bayo yeyona nto inokubangela ukukhethwa kweflange xa kuyilwa, kugcinwa kwaye kuhlaziywa inkqubo yepayipi. Endaweni yoko, kufuneka kuqwalaselwe ujongano lweflange nombhobho kunye neegaskets ezisetyenziswayo ukuqinisekisa ubungakanani obufanelekileyo. Ukongeza koku, ezinye izinto eziqhelekileyo zezi zilandelayo:

- Ububanzi obungaphandle: Ububanzi obungaphandle bumgama ophakathi kwemiphetho emibini echaseneyo yobuso beflange.

- Ubukhulu: Ubukhulu bulinganiswa ukusuka ngaphandle komphetho.

- Ububanzi beSangqa seBolt: Lo ngumgama ophakathi kwemingxuma yebolt elinganiswe ukusuka embindini ukuya embindini.

- Ubungakanani bepayipi: Ubungakanani bepayipi bubungakanani obuhambelana neflange.

- I-Nominal Bore: I-nominal bore bubungakanani bobubanzi bangaphakathi be-flange connector.

Uhlu lweFlange kunye neNqanaba leNkonzo

Iiflanges zahlulwe ngokuyintloko ngokukwazi kwazo ukumelana namaqondo obushushu ahlukeneyo kunye noxinzelelo. Zichazwa ngokusebenzisa oonobumba okanye izimamva "#", "lb" okanye "class". Ezi zizimamva ezitshintshanayo kwaye ziyahluka ngokwengingqi okanye umthengisi. Uhlu olwaziwayo ludweliswe ngezantsi:

- 150#

- 300#

- 600#

- 900#

- 1500#

- 2500#

Ukunyamezela uxinzelelo kunye nobushushu obufanayo kuyahluka ngokuxhomekeke kwizinto ezisetyenzisiweyo, uyilo lweflange kunye nobukhulu beflange. Nangona kunjalo, okukuphela kokungaguquguqukiyo kukukala koxinzelelo, okuyehla njengoko ubushushu bunyuka.

Uhlobo loBuso beFlange

Uhlobo lobuso nalo luphawu olubaluleke kakhulu olunempembelelo enkulu ekusebenzeni kokugqibela kunye nobomi benkonzo yeflange. Ke ngoko, ezinye zezona ntlobo zibalulekileyo zobuso beflange ziyahlalutywa ngezantsi:

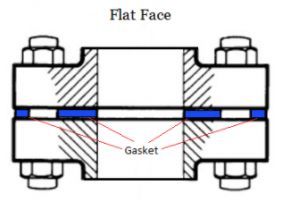

1. Iflegi ethe tyaba (FF)

Umphezulu we-gasket yeflange ethe tyaba ukwindawo efanayo nomphezulu wesakhelo esinamabholiti. Izinto ezisebenzisa iiflange ezithe tyaba zihlala zezo zenziwe ngeemolds ukuze zihambelane neflange okanye isigqubuthelo seflange. Iiflange ezithe tyaba akufuneki zibekwe kwiiflanges ezisemacaleni eziguquliweyo. I-ASME B31.1 ithi xa kuhlanganiswa iiflanges zesinyithi ezithe tyaba kwiiflanges zesinyithi sekhabhoni, ubuso obuphakanyisiweyo kwiiflanges zesinyithi sekhabhoni kufuneka bususwe kwaye kufuneka i-gasket epheleleyo yobuso. Oku kwenzelwa ukuthintela iiflanges zesinyithi ezincinci, ezibuthathaka ukuba zingatshizi kwindawo engenanto eyenziwe yimpumlo ephakanyisiweyo yeflange yesinyithi sekhabhoni.

Olu hlobo lobuso beflange lusetyenziswa ekwenzeni izixhobo kunye neevalvu kuzo zonke izicelo apho kwenziwa khona intsimbi ephosiweyo. Intsimbi ephosiweyo ibuthathaka ngakumbi kwaye idla ngokusetyenziselwa kuphela ubushushu obuphantsi kunye noxinzelelo oluphantsi. Ubuso obuthe tyaba buvumela zombini iiflange ukuba ziqhagamshelane ngokupheleleyo phezu komphezulu wonke. Iiflanges ezithe tyaba (FF) zinomphezulu woqhagamshelwano olingana nobude bemisonto yeflanges. Iiwashers zobuso ezipheleleyo zisetyenziswa phakathi kweeflanges ezimbini ezithe tyaba kwaye zihlala zithambile. Ngokutsho kwe-ASME B31.3, iiflanges ezithe tyaba akufuneki zidityaniswe neeflanges eziphakamileyo ngenxa yokuba kunokwenzeka ukuba kubekho ukuvuza okuvela kwi-flange joint ephumayo.

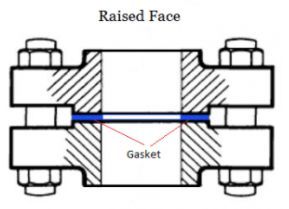

2. I-Flange ePhakanyisiweyo (RF)

I-flange yobuso obuphakanyisiweyo yeyona ixhaphakileyo esetyenziswa kwizicelo zabenzi kwaye kulula ukuyiqonda. Ibizwa ngokuba yi-convex kuba ubuso be-gasket bukwindawo engaphezulu kobuso beringi ye-bolt. Uhlobo ngalunye lobuso lufuna ukusetyenziswa kweentlobo ezahlukeneyo zee-gasket, kubandakanya iintlobo ngeentlobo zee-tabs zeringi ezisicaba kunye nee-composites zesinyithi ezifana neefom ze-spiral-wound kunye ne-double-sheathed.

Iiflange zeRF zenzelwe ukugxininisa uxinzelelo olongezelelweyo kwindawo encinci ye-gasket, ngaloo ndlela kuphuculwe ulawulo loxinzelelo lwejoyinti. Ububanzi kunye nokuphakama ngokwenqanaba loxinzelelo kunye nobubanzi kuchazwe kwi-ASME B16.5. Inqanaba loxinzelelo lweFlange lichaza ukuphakama kobuso obuphakanyiswayo. Iiflange zeRF zenzelwe ukugxininisa uxinzelelo olongezelelweyo kwindawo encinci ye-gasket, ngaloo ndlela zonyusa amandla okulawula uxinzelelo lwejoyinti. Ububanzi kunye nokuphakama ngokweklasi yoxinzelelo kunye nobubanzi kuchazwe kwi-ASME B16.5. Ukulinganiswa kweflange yoxinzelelo.

3. I-Flange yeringi (RTJ)

Xa kufuneka isitywino sentsimbi ukuya kwisinyithi phakathi kweeflanges ezidibeneyo (nto leyo eyimfuneko yokusetyenziswa koxinzelelo oluphezulu kunye nobushushu obuphezulu, oko kukuthi, ngaphezulu kwe-700/800 C°), kusetyenziswa iRing Joint Flange (RTJ).

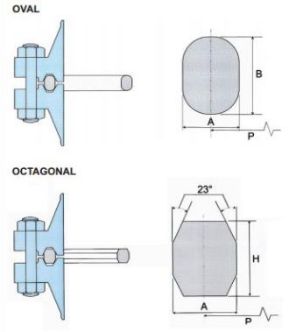

I-flange ye-ring joint ine-groove ejikelezayo evumela i-gasket ye-ring joint (e-oval okanye e-rectangular).

Xa ii-flanges ezimbini ze-ring joint zibotshelelwe kunye zize ziqiniswe, amandla e-bolt asetyenzisiweyo aguqula i-gasket kwi-groove ye-flange, nto leyo eyenza i-seal eqinileyo kakhulu ukusuka kwi-metal ukuya kwi-metal. Ukuze kufezwe oku, izinto ze-gasket ye-ring joint kufuneka zithambile (zibe mdaka ngakumbi) kunezinto ze-flanges.

Iiflange zeRTJ zingavalwa ngee-gasket zeRTJ zeentlobo ezahlukeneyo (R, RX, BX) kunye neeprofayili (umz., i-octagonal/elliptical yohlobo lwe-R).

Eyona gasket yeRTJ ixhaphakileyo luhlobo lwe-R olunecandelo elinqamlezileyo elinamacala asibhozo, njengoko luqinisekisa isitywina esomeleleyo kakhulu (icandelo elinqamlezileyo elinamacala asibhozo lolona hlobo ludala). Nangona kunjalo, uyilo lwe-"flat groove" luyamkela zombini iintlobo zeegasket zeRTJ ezinecandelo elinqamlezileyo elinamacala asibhozo okanye asibhozo.

4. Iiflange zolwimi kunye neegroove (T & G)

Iiflange ezimbini zolwimi kunye neegroove (ubuso be-T & G) zihambelana ngokugqibeleleyo: enye iflange ineringi ephakanyisiweyo kwaye enye inee-groove apho zingena khona ngokulula (ulwimi lungena kwigroove luze luvale ijoyinti).

Iiflange zolwimi kunye neegroove ziyafumaneka ngobukhulu obukhulu nobuncinci.

5. Iiflanges zeNdoda neNdoda (M & F)

Ngokufana neeflanges zolwimi kunye neegroove, iiflanges zamadoda nabafazi (iintlobo zobuso be-M & F) ziyahambelana.

Iflange enye inendawo edlula umphezulu wayo, iflange yamadoda, kwaye enye iflange ineengxinano ezifanayo ezifakwe kumphezulu ojongeneyo, iflange yabasetyhini.

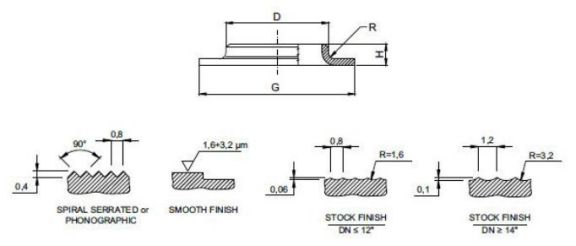

Ukugqitywa komphezulu weFlange

Ukuze kuqinisekiswe ukuba iflange ilingana ngokugqibeleleyo ne-gasket kunye neflange yokudibana, indawo yomphezulu weflange ifuna inqanaba elithile loburhabaxa (ukugqitywa kweflange ye-RF kunye ne-FF kuphela). Uhlobo loburhabaxa bomphezulu wobuso beflange luchaza uhlobo "lokugqitywa kweflange".

Iintlobo eziqhelekileyo zezi: i-stock, i-concentric serrated, i-spiral serrated kunye ne-smooth flange faces.

Kukho izinto ezine ezisisiseko zokugqiba umphezulu wee-flanges zentsimbi, nangona kunjalo, injongo eqhelekileyo yalo naluphi na uhlobo lokugqiba umphezulu we-flange kukuvelisa uburhabaxa obufunekayo kumphezulu we-flange ukuqinisekisa ukulingana okuqinileyo phakathi kwe-flange, i-gasket kunye ne-flange yokudibana ukuze kubonelelwe ngophawu olusemgangathweni.

Ixesha lokuthumela: Okthobha-08-2023