Intsimbi engagqwaliyo sisifinyezo sentsimbi engagqwaliyo engagqwaliyo engagqwaliyo, umoya, umphunga, amanzi kunye nezinye izinto ezibuthathaka ezigqwaliyo okanye intsimbi engagqwaliyo yaziwa ngokuba yintsimbi engagqwaliyo; kwaye iya kuxhathisa izinto ezigqwaliyo ezisebenzisa iikhemikhali (ii-asidi, ii-alkali, iityuwa, kunye nezinye izinto ezifakwa kwiikhemikhali) ukugqwala kwentsimbi kubizwa ngokuba yintsimbi engagqwaliyo engagqwaliyo.

Intsimbi engatyiwayo ibhekisa kumoya, umphunga, amanzi kunye nezinye izinto ezibuthathaka ezibolayo kunye nee-asidi, ii-alkali, iityuwa kunye nezinye izinto ezinobungozi ezisebenzisa iikhemikhali ukubola kwentsimbi, okwaziwa ngokuba yintsimbi engatyiwayo engatyiwayo. Ngokwesiqhelo, intsimbi engatyiwayo engatyiwayo ebolayo ebizwa ngokuba yintsimbi engatyiwayo, kunye nentsimbi engatyiwayo ebolayo ebizwa ngokuba yintsimbi engatyiwayo. Ngenxa yokwahluka kwimilo yeekhemikhali kwezi zimbini, eyokuqala ayinyanzelekanga ukuba imelane nokubola kwe-chemical media, ngelixa eyokugqibela idla ngokuba yintsimbi engatyiwayo. Ukuxhathisa ukubola kwentsimbi engatyiwayo kuxhomekeke kwizinto ezidityanisiweyo ezikwintsimbi.

Ulwahlulo Oluqhelekileyo

Ngokwentlangano ye-metallurgical

Ngokubanzi, ngokwenkqubo yesinyithi, iintsimbi eziqhelekileyo ezingenasici zahlulwe zibe ziindidi ezintathu: iintsimbi ezingenasici ze-austenitic, iintsimbi ezingenasici ze-ferritic kunye neentsimbi ezingenasici ze-martensitic. Ngokusekelwe kwindlela esisiseko yesinyithi kwezi ndidi zintathu, iintsimbi ezimbini, iintsimbi ezingenasici eziqinisa imvula kunye neentsimbi ezine-alloy ephezulu eziqulethe ngaphantsi kwe-50% yentsimbi zifumaneka kwiimfuno ezithile kunye neenjongo ezithile.

1. Intsimbi engagqwaliyo yase-Austenitic

Isakhiwo sekristale ye-cubic esijonge ubuso ukuya kubuso be-austenitic organization (CY phase) silawulwa yi-non-magnetic, ikakhulu ngokusebenza ngokubandayo ukuze siqiniswe (kwaye sinokukhokelela kwinqanaba elithile le-magnetism). I-American Iron and Steel Institute inika uluhlu lweeleyibhile zamanani ezingama-200 kunye nama-300, ezifana ne-304.

2. Intsimbi engagqwaliyo yeFerritic

Isakhiwo sekristale yetyhubhu esisekwe emzimbeni se-ferrite (isigaba) sinamandla, sinobunewunewu, ngokubanzi asinakwenziwa lukhuni ngonyango lobushushu, kodwa ukusebenza ngokubandayo kunokuyenza ibe yintsimbi engagqwaliyo eyomeleleyo kancinci. I-American Iron and Steel Institute iya ku-430 kunye ne-446 yeleyibhile.

3. Intsimbi engagqwaliyo yeMartensitic

I-matrix ilungelelaniswa ne-martensitic (i-cubic okanye i-cubic egxile emzimbeni), i-magnetic, ngonyango lobushushu ingakwazi ukulungisa iipropati zayo zoomatshini zentsimbi engagqwaliyo. I-American Iron and Steel Institute iphawulwe ngamanani angama-410, 420, kunye nama-440. I-Martensite inolungelelaniso lwe-austenitic kumaqondo obushushu aphezulu, olunokuguqulwa lube yi-martensite (oko kukuthi iqiniswe) xa ipholiswe kubushushu begumbi ngesantya esifanelekileyo.

4. Intsimbi engenasici yohlobo lwe-Austenitic yi-ferrite (duplex)

I-matrix ine-austenitic kunye ne-ferrite two-phase organization, apho umxholo we-lesser phase matrix ngokubanzi ungaphezulu kwe-15%, i-magnetic, inokomelezwa ngokusebenza okubandayo kwentsimbi engagqwaliyo, i-329 yintsimbi engagqwaliyo eqhelekileyo ye-duplex. Xa ithelekiswa nentsimbi engagqwaliyo ye-austenitic, intsimbi ye-duplex enamandla aphezulu, ukumelana nokugqwala kwe-intergranular kunye nokugqwala koxinzelelo lwe-chloride kunye nokugqwala kwe-pitting kuphuculwe kakhulu.

5. Intsimbi engagqwaliyo yokuqiniswa kwemvula

I-matrix ilungelelaniswa yi-austenitic okanye i-martensitic, kwaye inokwenziwa lukhuni ngonyango lokuqinisa imvula ukuze iqine intsimbi engagqwali. I-American Iron and Steel Institute ifikelela kuthotho lweeleyibhile zedijithali ezingama-600, ezifana ne-630, oko kukuthi, i-17-4PH.

Ngokubanzi, ukongeza kwii-alloys, ukumelana nokugqwala kwentsimbi engagqwaliyo ye-austenitic kuphezulu, kwindawo engenangcolisi kangako, ungasebenzisa intsimbi engagqwaliyo ye-ferritic, kwiindawo ezinongcolisi kancinci, ukuba izinto ezifunekayo ukuze zibe namandla aphezulu okanye ubunzima obuphezulu, ungasebenzisa intsimbi engagqwali ye-martensitic kunye nentsimbi engagqwaliyo yemvula.

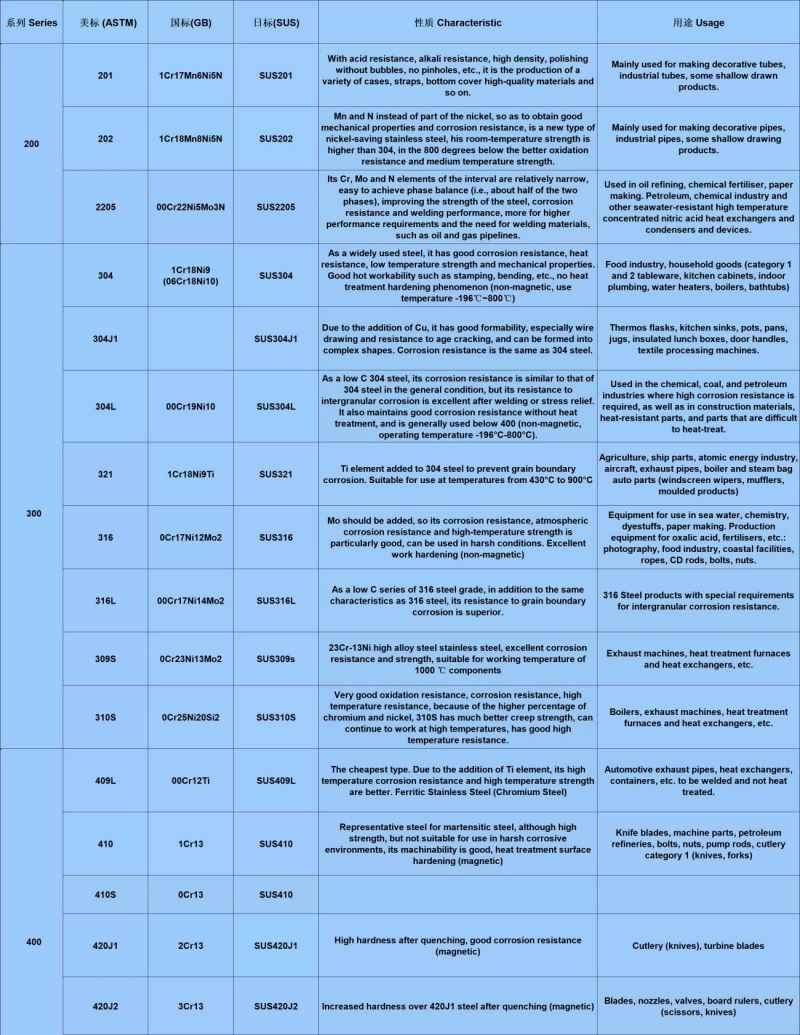

Iimpawu kunye nokusetyenziswa

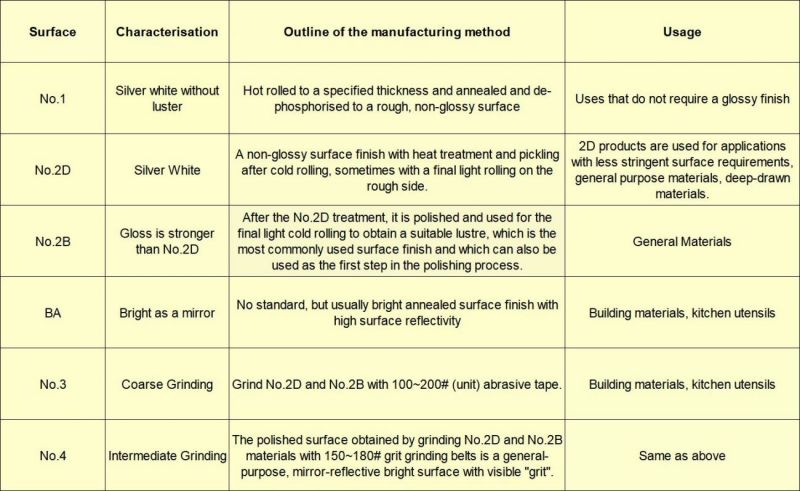

Inkqubo yomphezulu

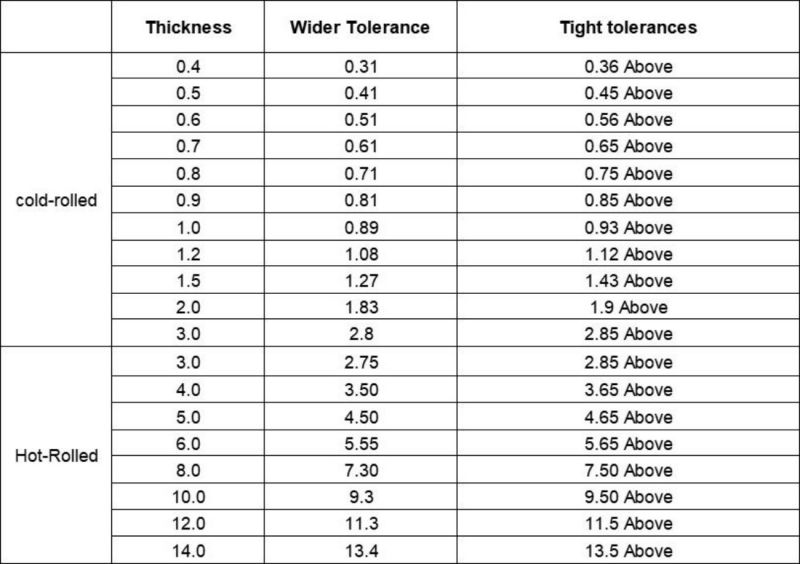

Ukwahluka kobukhulu

1. Ngenxa yokuba oomatshini bokugaya intsimbi bekwinkqubo yokuqengqeleka, imiqulu ifudunyezwa kukuguquka okuncinci, okubangela ukuqengqeleka kobukhulu bepleyiti, ngokubanzi ibe nkulu phakathi kwamacala amabini ebhityileyo. Ekulinganiseni ubukhulu bepleyiti, imithetho yelizwe kufuneka ilinganiswe phakathi kwentloko yepleyiti.

2. Isizathu sokunyamezelana sisekelwe kwimarike kunye neemfuno zabathengi, ngokubanzi zahlulwe zibe zii-tolerances ezinkulu nezincinci.

V. Iimfuno zokuvelisa, zokuhlola

1. Ipleyiti yombhobho

① ii-butt joints ze-tube plate ezidibeneyo zokuhlolwa kwe-100% yemitha okanye i-UT, inqanaba elifanelekileyo: RT: Ⅱ UT: inqanaba le-Ⅰ;

② Ukongeza kwintsimbi engagqwaliyo, unyango lokunciphisa uxinzelelo loxinzelelo lwepayipi yombhobho oludibeneyo;

③ ipleyiti yetyhubhu ukuphambuka kobubanzi bebhulorho yomngxuma: ngokwefomula yokubala ububanzi bebhulorho yomngxuma: B = (S - d) - D1

Ububanzi obuncinci bebhulorho yomngxuma: B = 1/2 (S - d) + C;

2. Unyango lobushushu bebhokisi yetyhubhu:

Intsimbi yekhabhoni, intsimbi ye-alloy ephantsi edityanisiweyo ene-partition-range partition yebhokisi yombhobho, kunye nebhokisi yombhobho yeendawo ezivulekileyo ezisecaleni ezingaphezulu kwe-1/3 yobubanzi bangaphakathi bebhokisi yombhobho wesilinda, ekusetyenzisweni kwe-welding yokunciphisa uxinzelelo unyango lobushushu, i-flange kunye nomphezulu wokutywina we-partition kufuneka ucutshungulwe emva konyango lobushushu.

3. Uvavanyo loxinzelelo

Xa uxinzelelo loyilo lwenkqubo yeqokobhe luphantsi kunoxinzelelo lwenkqubo yetyhubhu, ukuze kujongwe umgangatho woqhagamshelo lwetyhubhu yokutshintsha ubushushu kunye neplate yetyhubhu

① Uxinzelelo lwenkqubo yeShell ukuze kunyuswe uxinzelelo lovavanyo ngenkqubo yepayipi ehambelana novavanyo lwehydraulic, ukujonga ukuba ngaba ukuvuza kwamalungu epayipi kuyavuza na. (Nangona kunjalo, kuyimfuneko ukuqinisekisa ukuba uxinzelelo oluphambili lwefilimu yegobolondo ngexesha lovavanyo lwehydraulic yi ≤0.9ReLΦ)

② Xa le ndlela ingasentla ingafanelekanga, iqokobhe linokuvavanywa nge-hydrostatic ngokwengcinezelo yokuqala emva kokudlula, emva koko uvavanyo lokuvuza kwe-ammonia okanye uvavanyo lokuvuza kwe-halogen lunokuvavanywa nge-hydrostatic.

Loluphi uhlobo lwentsimbi engagqwaliyo ekulula ukugqwala?

Kukho izinto ezintathu eziphambili ezichaphazela ukugqwala kwentsimbi engagqwaliyo:

1. Umxholo wezinto ezixutyiweyo. Ngokubanzi, umxholo we-chromium kwintsimbi eyi-10.5% akulula ukuwugqwala. Okukhona umxholo we-chromium kunye ne-nickel uxhathisa ukugqwala uphezulu, njengomxholo we-nickel wezinto ezingama-304 we-85 ~ 10%, umxholo we-chromium we-18% ~ 20%, loo ntsimbi ingagqwali ngokubanzi ayigqwali.

2. Inkqubo yokunyibilikisa yomenzi iya kuchaphazela nokumelana nokugqwala kwentsimbi engagqwali. Iteknoloji yokunyibilikisa ilungile, izixhobo eziphambili, iteknoloji ephucukileyo, isityalo esikhulu sentsimbi engagqwali zombini kulawulo lwezinto ezixutywayo, ukususwa kokungcola, ulawulo lobushushu bokupholisa i-billet lunokuqinisekiswa, ngoko umgangatho wemveliso uzinzile kwaye uthembekile, umgangatho olungileyo wangaphakathi, akukho lula ukuwugqwalisa. Ngokwahlukileyo koko, ezinye izixhobo zesityalo sentsimbi encinci zibuyela umva, iteknoloji ebuyela umva, inkqubo yokunyibilikisa, ukungcola akunakususwa, imveliso yeemveliso iya kugqwala ngokuqinisekileyo.

3. Imeko-bume yangaphandle. Indawo eyomileyo nengena umoya ayilula ukuyigqwala, ngelixa ukufuma komoya, imozulu eqhubekayo yemvula, okanye umoya oqulethe iasidi kunye ne-alkalinity yendawo kulula ukuyigqwala. Isinyithi esingenasici, ukuba imeko-bume ejikelezileyo imbi kakhulu, nayo igqwala.

Amabala okugqwala entsimbi engagqwaliyo ungawajongana njani nawo?

1. Indlela yekhemikhali

Nge-pickling paste okanye i-spray yokunceda iindawo zayo ezigqwalileyo ukuba ziphinde zivuselele ukwakheka kwefilimu ye-chromium oxide ukuze kubuyiselwe ukumelana kwayo nokugqwala, emva kwe-pickling, ukuze kususwe zonke izinto ezingcolisayo kunye neentsalela ze-asidi, kubaluleke kakhulu ukwenza uhlambululo olufanelekileyo ngamanzi. Emva kokuba yonke into icutshungulwe kwaye ipholishwe kwakhona ngezixhobo zokupholisha, ingavalwa nge-wax yokupholisha. Kwiindawo ezincinci zokugqwala, ipetroli ye-1:1 ingasetyenziswa, umxube weoyile kunye neragi ecocekileyo yokususa amabala okugqwala.

2. Iindlela zoomatshini

Ukucoca isanti, ukucoca ngeglasi okanye iinxalenye zeseramikhi, ukuqhekeza, ukuxubha kunye nokupolisha. Iindlela zoomatshini zinamandla okususa ungcoliseko olubangelwa zizinto ezisusiweyo ngaphambili, izinto zokupolisha okanye izinto ezisusiweyo. Zonke iintlobo zongcoliseko, ingakumbi iinxalenye zesinyithi zangaphandle, zinokuba ngumthombo wokubola, ingakumbi kwiindawo ezifumileyo. Ke ngoko, iindawo ezicociwe ngoomatshini kufuneka zicocwe ngokusesikweni phantsi kweemeko ezomileyo. Ukusetyenziswa kweendlela zoomatshini kucoca kuphela umphezulu wazo kwaye akutshintshi ukumelana nokubola kwezinto ngokwazo. Ke ngoko, kucetyiswa ukuba uphinde upolise umphezulu ngezixhobo zokupolisha kwaye uwuvale nge-wax yokupolisha emva kokucoca ngoomatshini.

Izixhobo ezisetyenziswa rhoqo kwiiklasi zentsimbi engenasici kunye neempawu

Intsimbi engagqwaliyo eyi-1.304. Yenye yeentsimbi ezingagqwaliyo ze-austenitic ezinokusetyenziswa okukhulu kunye nokusetyenziswa okubanzi, zifanelekile ukuvelisa iindawo zokubumba ezitsalwe nzulu kunye nemibhobho ye-asidi, izikhongozeli, iindawo zesakhiwo, iintlobo ngeentlobo zezixhobo, njl. Ingavelisa nezixhobo kunye neenxalenye ezingezizo zemagnethi, ezinobushushu obuphantsi.

Intsimbi engagqwaliyo eyi-2.304L. Ukuze kusonjululwe imvula ye-Cr23C6 ebangelwa yintsimbi engagqwaliyo eyi-304 kwezinye iimeko kukho utyekelo olukhulu lokugqwala phakathi kwe-granular kunye nophuhliso lwentsimbi engagqwaliyo ye-austenitic ene-carbon ephantsi kakhulu, imeko yayo yokumelana nokugqwala phakathi kwe-granular ingcono kakhulu kunentsimbi engagqwali eyi-304. Ukongeza kumandla aphantsi kancinci, ezinye iipropati ezinentsimbi engagqwali eyi-321, ezisetyenziselwa kakhulu izixhobo kunye nezixhobo ezichasene nokugqwala azinakufakelwa unyango lwesisombululo, zingasetyenziselwa ukwenza iintlobo ezahlukeneyo zomzimba wezixhobo.

Intsimbi engagqwaliyo eyi-3.304H. Isebe langaphakathi lentsimbi engagqwaliyo eyi-304, iqhekeza le-carbon mass kwi-0.04% ~ 0.10%, ukusebenza kobushushu obuphezulu kungcono kunentsimbi engagqwaliyo eyi-304.

Intsimbi engagqwaliyo eyi-4.316. Kwintsimbi ye-10Cr18Ni12 esekwe ekongezweni kwe-molybdenum, ukuze intsimbi ibe nokumelana okuhle ekunciphiseni imidiya kunye nokuxhathisa ukugqwala kwemingxuma. Kumanzi olwandle nakwezinye iindawo, ukumelana nokugqwala kungcono kunentsimbi engagqwali eyi-304, esetyenziselwa ikakhulu izinto ezichasene nokugqwala kwemingxuma.

Intsimbi engagqwaliyo eyi-5.316L. Intsimbi yekhabhoni ephantsi kakhulu, enokumelana kakuhle nokugqwala okubukhali phakathi kweegranular, ifanelekile ekwenzeni ubungakanani obukhulu becandelo elihlanganisiweyo lezixhobo ezidityanisiweyo, ezifana nezixhobo ze-petrochemical kwizixhobo ezimelana nokugqwala.

Intsimbi engagqwaliyo eyi-6.316H. Isebe langaphakathi lentsimbi engagqwaliyo eyi-316, iqhekeza le-carbon mass eliyi-0.04%-0.10%, ukusebenza kobushushu obuphezulu kungcono kunentsimbi engagqwaliyo eyi-316.

Intsimbi engagqwaliyo eyi-7.317. Ukumelana nokugqwala kunye nokumelana nokuqhekeka kwentsimbi kungcono kunentsimbi engagqwaliyo eyi-316L, esetyenziswa ekwenzeni izixhobo ezichasene nokugqwala ze-petrochemical kunye ne-organic acid.

Intsimbi engagqwaliyo engu-8.321. Intsimbi engagqwaliyo ye-austenitic ezinzileyo ye-titanium, eyongeza i-titanium ukuphucula ukumelana nokugqwala phakathi kwe-granular, kwaye ineempawu ezintle zoomatshini kubushushu obuphezulu, ingathathelwa indawo yintsimbi engagqwali ye-austenitic ene-carbon ephantsi kakhulu. Ukongeza kukumelana nokugqwala kubushushu obuphezulu okanye i-hydrogen kunye nezinye iziganeko ezikhethekileyo, imeko iyonke ayikhuthazwa.

9.347 intsimbi engagqwaliyo. Intsimbi engagqwaliyo ye-austenitic ezinzileyo yi-niobium, i-niobium yongezwe ukuphucula ukumelana nokugqwala kwe-intergranular, ukumelana nokugqwala kwi-asidi, i-alkali, ityuwa kunye nezinye izinto ezigqwaliyo ngentsimbi engagqwali ye-321, ukusebenza kakuhle kwe-welding, ingasetyenziswa njengezixhobo ezimelana nokugqwala kunye nentsimbi engagqwaliyo esetyenziselwa ikakhulu amandla obushushu, amasimi e-petrochemical, njengokuveliswa kwezikhongozeli, iipayipi, abatshintshi bobushushu, imingxunya, izitofu zoshishino kwityhubhu yesithando somlilo kunye ne-thermometer yetyhubhu yesithando somlilo njl.njl.

Intsimbi engagqwaliyo eyi-10.904L. Intsimbi engagqwaliyo ye-austenitic epheleleyo kakhulu, intsimbi engagqwaliyo ye-austenitic eyenziwe yiFinland Otto Kemp, iqhekeza layo le-nickel mass eliyi-24% ukuya kwi-26%, iqhekeza le-carbon mass elingaphantsi kwe-0.02%, ukumelana nokugqwala okugqwesileyo, kwii-asidi ezingezizo i-oxidizing ezifana ne-sulfuric, i-acetic, i-formic kunye ne-phosphoric acid inokumelana nokugqwala okuhle kakhulu, kwaye kwangaxeshanye inokumelana nokugqwala okuqhekekileyo kunye nokuxhathisa iimpawu zokugqwala okuxineneyo. Ifanelekile kwiindidi ezahlukeneyo ze-sulfuric acid ezingaphantsi kwama-70℃, kwaye inokumelana nokugqwala okuhle kwi-acetic acid kunye ne-acid exutyiweyo ye-formic acid kunye ne-acetic acid yalo naliphi na iqondo kunye nalo naliphi na iqondo lobushushu phantsi koxinzelelo oluqhelekileyo. I-ASMESB-625 yokuqala iyichaza njenge-alloys esekelwe kwi-nickel, kwaye umgangatho omtsha uyichaza njengentsimbi engagqwali. I-China kuphela i-015Cr19Ni26Mo5Cu2 steel eqikelelweyo, abavelisi bezixhobo ezimbalwa zaseYurophu abasebenzisa intsimbi engagqwali ye-904L, njengetyhubhu yokulinganisa i-flowmeter yobunzima be-E + H, isetyenziswa kwintsimbi engagqwali ye-904L, ityesi yewotshi yeRolex ikwasetyenziswa kwintsimbi engagqwali ye-904L.

Intsimbi engagqwaliyo eyi-11.440C. Intsimbi engagqwaliyo yeMartensitic, intsimbi engagqwaliyo eqina, intsimbi engagqwaliyo ekwimeko yobunzima obuphezulu, ubunzima be-HRC57. Isetyenziswa kakhulu ekuveliseni ii-nozzles, ii-bearings, ii-valve, ii-valve spools, izihlalo zee-valve, imikhono, iziqu zee-valve, njl.njl.

Intsimbi engagqwaliyo eyi-12.17-4PH. Intsimbi engagqwaliyo eqinisa i-martensitic precipitation, ubulukhuni be-HRC44, enamandla aphezulu, ubulukhuni kunye nokumelana nokugqwala, ayinakusetyenziswa kumaqondo obushushu aphezulu kune-300 ℃. Inokumelana okuhle nokugqwala kwii-asidi zomoya kunye neetyuwa ezinyibilikisiweyo, kwaye ukumelana kwayo nokugqwala kufana noko kwe-304 stainless steel kunye ne-430 stainless steel, esetyenziswa ekwenziweni kwamaqonga aselwandle, ii-turbine blades, ii-spools, izihlalo, imikhono kunye neziqu zeevalvu.

Kwimisebenzi yezixhobo, kunye nemiba eqhelekileyo kunye neendleko, umyalelo wokukhetha intsimbi engagqwaliyo ye-austenitic yi-304-304L-316-316L-317-321-347-904L, apho i-317 ingasetyenziswa rhoqo, i-321 ayikhuthazwa, i-347 isetyenziselwa ukugqwala kobushushu obuphezulu, i-904L yinto esetyenziswa rhoqo kwezinye izinto zabavelisi ngabanye, uyilo aluyi kuthatha nyathelo lokukhetha i-904L.

Ekukhetheni uyilo lwezixhobo, ngokuqhelekileyo kuya kubakho izixhobo kunye nezixhobo zepayipi ezahlukeneyo, ingakumbi kwiimeko zobushushu obuphezulu, kufuneka sinikele ingqalelo ekhethekileyo ekukhetheni izixhobo zezixhobo ukuhlangabezana nezixhobo zenkqubo okanye ubushushu boyilo lwepayipi kunye noxinzelelo loyilo, ezifana nombhobho wentsimbi ye-chrome molybdenum obushushu obuphezulu, ngelixa izixhobo zokukhetha intsimbi engagqwali, ngoko ke kunokwenzeka ukuba kube yingxaki, kufuneka uye kujonga ubushushu bezinto ezifanelekileyo kunye negauge yoxinzelelo.

Ekukhetheni uyilo lwezixhobo, kudla ngokudibana neenkqubo ezahlukeneyo, uthotho, amanqanaba entsimbi engagqwali, ukhetho kufuneka lusekelwe kwimidiya ethile yenkqubo, ubushushu, uxinzelelo, iindawo ezixinezelekileyo, ukugqwala kunye neendleko kunye nezinye iimbono.

Ixesha lokuthumela: Oktobha-11-2023