Unyango lobushushu lubhekisa kwinkqubo yobushushu besinyithi apho izinto zifudunyezwa, zibanjwa kwaye zipholiswe ngokufudumeza zikwimeko eqinileyo ukuze kufunyanwe ulungiselelo kunye neempawu ezifunekayo.

I. Unyango lobushushu

1, Ukulungisa: iziqwenga zentsimbi okanye zentsimbi ezifudunyezwayo ukuya kwinqanaba elibalulekileyo le-AC3 okanye i-ACM ngaphezu kobushushu obufanelekileyo ukugcina ixesha elithile emva kokupholisa emoyeni, ukuze kufumaneke uhlobo lwe-pearlitic lombutho wenkqubo yonyango lobushushu.

2, I-Annealing: i-eutectic steel workpiece efudunyezwa ukuya kwi-AC3 ngaphezulu kwama-20-40 degrees, emva kokubamba ixesha elithile, kunye nesithando somlilo esipholile kancinci (okanye singcwatywe kwisanti okanye kwi-lime cooling) ukuya kuma-500 degrees ngaphantsi kokupholisa kwinkqubo yonyango lobushushu bomoya.

3, Unyango lobushushu lwesisombululo esiqinileyo: i-alloy ifudunyezwa ukuya kummandla wobushushu obuphezulu besigaba esinye sobushushu obungaguqukiyo ukuze igcinwe, ukuze isigaba esigqithisileyo sinyibilike ngokupheleleyo sibe sisisombululo esiqinileyo, size emva koko sipholiswe ngokukhawuleza ukuze kufumaneke inkqubo yonyango lobushushu lwesisombululo esiqinileyo esingaphezulu kwesaturated.

4、Ukwaluphala:Emva konyango lobushushu oluqinileyo okanye ukuguqulwa kweplastiki ebandayo ye-alloy, xa ibekwe kubushushu begumbi okanye igcinwe kubushushu obuphezulu kancinci kunobushushu begumbi, imeko yeempawu zayo iyatshintsha ngokuhamba kwexesha.

5, Unyango lwesisombululo esiqinileyo: ukuze i-alloy kwiindidi ezahlukeneyo ichithwe ngokupheleleyo, yomeleze isisombululo esiqinileyo kwaye iphucule ukuqina kunye nokumelana nokugqwala, isuse uxinzelelo kunye nokuthamba, ukuze kuqhubeke nokucutshungulwa kokubumba.

6, Unyango lokwaluphala: ukufudumeza nokubamba kubushushu bokuna kwesigaba sokuqinisa, ukuze ukuna kwesigaba sokuqinisa kube lukhuni, kuqine, kuphucule amandla.

7, Ukucima: i-austenitization yentsimbi emva kokupholisa ngesantya esifanelekileyo sokupholisa, ukuze umsebenzi ube kwicandelo elinqamlezileyo lazo zonke okanye uluhlu oluthile lwesakhiwo sombutho esingazinzanga njengokuguqulwa kwe-martensite kwenkqubo yonyango lobushushu.

8, Ukushisa: umsebenzi ocinyiweyo uya kufudunyezwa ukuya kwinqanaba elibalulekileyo le-AC1 ngaphantsi kobushushu obufanelekileyo kangangexesha elithile, uze upholiswe ngokuhambelana neemfuno zendlela, ukuze kufunyanwe ulungiselelo olufunekayo kunye neempawu zenkqubo yonyango lobushushu.

9, I-carbonitriding yentsimbi: I-carbonitriding ifikelela kumaleko womphezulu wentsimbi ngaxeshanye ingena kwinkqubo yekhabhoni ne-nitrogen. I-carbonitriding yesiko ikwaziwa ngokuba yi-cyanide, i-carbonitriding yegesi yobushushu obuphakathi kunye ne-carbonitriding yegesi yobushushu obuphantsi (oko kukuthi i-nitrocarburizing yegesi) isetyenziswa kakhulu. Injongo ephambili ye-carbonitriding yegesi yobushushu obuphakathi kukuphucula ubulukhuni, ukumelana nokuguguleka kunye namandla okudinwa kwentsimbi. I-carbonitriding yegesi yobushushu obuphantsi ukuya kwi-nitriding-based, injongo yayo ephambili kukuphucula ukumelana nokuguguleka kwentsimbi kunye nokumelana nokuluma.

10, Unyango lokunciphisa (ukucima nokunciphisa): isiko eliqhelekileyo liya kucinywa kwaye lincitshiswe kumaqondo obushushu aphezulu xa lidityaniswa nonyango lobushushu olwaziwa ngokuba lunyango lokunciphisa. Unyango lokunciphisa lusetyenziswa kakhulu kwiindawo ezahlukeneyo ezibalulekileyo zesakhiwo, ingakumbi ezo zisebenza phantsi kwemithwalo etshintshanayo yeentonga zokudibanisa, iibholiti, iigiya kunye neeshafti. Ukunciphisa emva konyango lokunciphisa ukuze ufumane ulungelelwaniso lwe-sohnite oluncitshisiweyo, iimpawu zayo zoomatshini zingcono kunobunzima obufanayo bolungelelwaniso lwe-sohnite oluqhelekileyo. Ubunzima bayo buxhomekeke kubushushu bokupholisa obuphezulu kunye nokuzinza kokupholisa kwentsimbi kunye nobukhulu becandelo lomsebenzi, ngokubanzi phakathi kwe-HB200-350.

11, Ukugquma: ngezinto zokugquma ziya kuba ziintlobo ezimbini zokunyibilikisa ukufudumeza okudityanisiweyo kunye nenkqubo yonyango lobushushu.

II.Tiimpawu zenkqubo

Unyango lobushushu besinyithi yenye yeenkqubo ezibalulekileyo kwimveliso yoomatshini, xa kuthelekiswa nezinye iinkqubo zoomatshini, unyango lobushushu ngokubanzi alutshintshi imo yesixhobo somsebenzi kunye nolwakhiwo lwaso lonke, kodwa ngokutshintsha isakhiwo sangaphakathi sesixhobo somsebenzi, okanye ukutshintsha ulwakhiwo lwekhemikhali kumphezulu wesixhobo somsebenzi, ukunika okanye ukuphucula ukusetyenziswa kweempawu zomsebenzi. Ibonakaliswa kukuphucuka komgangatho wangaphakathi wesixhobo somsebenzi, oqhele ukungabonakali emehlweni. Ukuze kwenziwe isixhobo somsebenzi sesinyithi sibe neempawu zoomatshini ezifunekayo, iimpawu zomzimba kunye neempawu zeekhemikhali, ukongeza kukhetho olufanelekileyo lwezinto kunye neentlobo ngeentlobo zenkqubo yokubumba, inkqubo yonyango lobushushu idla ngokuba yimfuneko. Intsimbi zezona zinto zisetyenziswa kakhulu kushishino loomatshini, i-metal microstructure complex, inokulawulwa ngonyango lobushushu, ngoko ke unyango lobushushu lwentsimbi luphawu oluphambili lonyango lobushushu besinyithi. Ukongeza, i-aluminium, i-copper, i-magnesium, i-titanium kunye nezinye ii-alloys nazo zinokuba lunyango lobushushu ukutshintsha iimpawu zayo zoomatshini, zomzimba nezekhemikhali, ukuze kufumaneke ukusebenza okwahlukileyo.

III.Tuyayiqhuba

Inkqubo yokunyanga ubushushu ngokubanzi ibandakanya ukufudumeza, ukubamba, ukupholisa iinkqubo ezintathu, ngamanye amaxesha ukufudumeza nokupholisa iinkqubo ezimbini kuphela. Ezi nkqubo ziqhagamshelwe omnye komnye, azinakuphazamiseka.

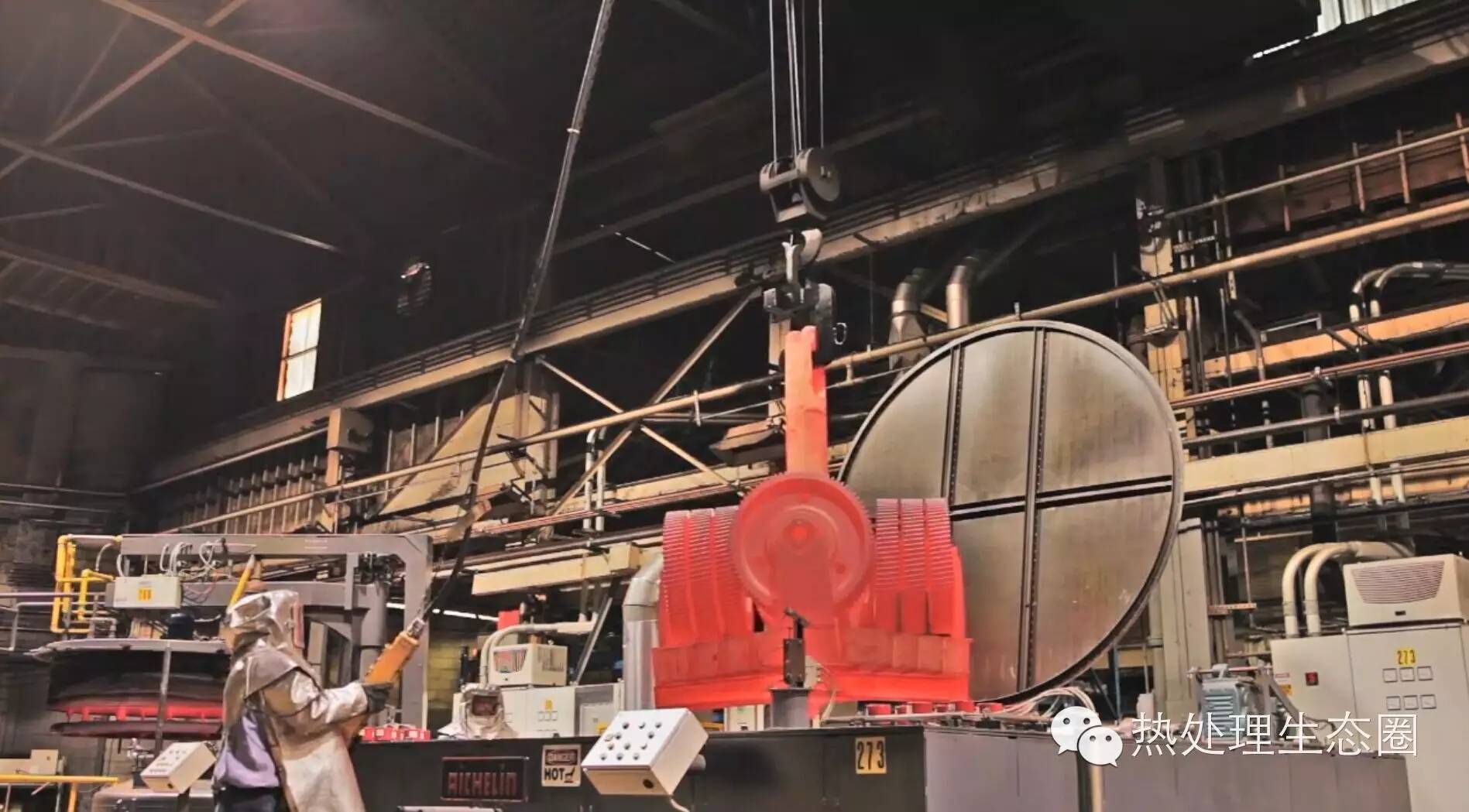

Ukufudumeza yenye yeenkqubo ezibalulekileyo zonyango lobushushu. Unyango lobushushu lwesinyithi lweendlela ezininzi zokufudumeza, eyokuqala kukusetyenziswa kwamalahle namalahle njengomthombo wobushushu, ukusetyenziswa kwamafutha olwelo kunye negesi kutshanje. Ukusetyenziswa kombane kwenza kube lula ukulawula ukufudumeza, kwaye kungabikho ungcoliseko lokusingqongileyo. Ukusetyenziswa kwezi mithombo zobushushu kunokufudunyezwa ngokuthe ngqo, kodwa nangetyuwa enyibilikisiweyo okanye isinyithi, ukuya kumasuntswana adadayo ukuze kufudunyezwe ngokungathanga ngqo.

Ukufudumeza ngesinyithi, umsebenzi ubonakala emoyeni, i-oxidation, ukubola kwekhabhoni rhoqo kwenzeka (oko kukuthi, umxholo wekhabhoni engaphezulu kwiindawo zentsimbi ukunciphisa), nto leyo enefuthe elibi kakhulu kwiimpawu zomphezulu weendawo eziphathwe ngobushushu. Ke ngoko, isinyithi kufuneka sibe kwindawo elawulwayo okanye kwindawo ekhuselayo, ityuwa enyibilikisiweyo kunye nokufudumeza nge-vacuum, kodwa kukwakho neendlela zokupakisha ezifumanekayo zokufudumeza ngokukhusela.

Ubushushu bokufudumeza yenye yezona parameters zibalulekileyo zenkqubo yonyango lobushushu, ukukhethwa kunye nolawulo lobushushu bokufudumeza, kukuqinisekisa umgangatho wonyango lobushushu lwemiba ephambili. Ubushushu bokufudumeza buyahluka ngokwezinto zesinyithi eziphathwayo kunye nenjongo yonyango lobushushu, kodwa ngokubanzi bufudunyezwa ngaphezu kobushushu besigaba sotshintsho ukuze kufunyanwe ulungiselelo lobushushu obuphezulu. Ukongeza, utshintsho lufuna ixesha elithile, ngoko ke xa umphezulu wentsimbi ufikelela kubushushu bokufudumeza obufunekayo, kodwa kufuneka kugcinwe kolu bushushu ixesha elithile, ukuze amaqondo obushushu angaphakathi nangaphandle ahambelane, ukuze utshintsho lwesakhiwo se-microstructure lugqitywe, olwaziwa ngokuba lixesha lokubamba. Ukusetyenziswa kobushushu obuphezulu bamandla kunye nonyango lobushushu bomphezulu, izinga lokufudumeza likhawuleza kakhulu, ngokubanzi akukho xesha lokubamba, ngelixa unyango lobushushu beekhemikhali lwexesha lokubamba ludla ngokuba lide.

Ukupholisa kukwalinyathelo elibalulekileyo kwinkqubo yonyango lobushushu, iindlela zokupholisa ngenxa yeenkqubo ezahlukeneyo, ikakhulu ukulawula izinga lokupholisa. Izinga lokupholisa eliqhelekileyo lelona licothayo, ukulungisa izinga lokupholisa kukhawuleza, ukucima izinga lokupholisa kukhawuleza. Kodwa kwanangenxa yeentlobo ezahlukeneyo zentsimbi kwaye zinemfuno ezahlukeneyo, ezifana nentsimbi eqinileyo enomoya ingacinywa ngesantya esifanayo sokupholisa njengesiqhelo.

IV.Pulwahlulo lweenkqubo

Inkqubo yokunyanga ubushushu besinyithi inokwahlulwahlulwa ngokubanzi ibe lunyango lonke lobushushu, unyango lobushushu bomphezulu kunye nonyango lobushushu beekhemikhali kwiindidi ezintathu. Ngokwendlela yokufudumeza, ubushushu bokufudumeza kunye nendlela yokuphola eyahlukeneyo, udidi ngalunye lunokwahlulwa lube ziinkqubo ezahlukeneyo zokunyanga ubushushu. Isinyithi esifanayo sisebenzisa iinkqubo ezahlukeneyo zokunyanga ubushushu, sinokufumana imibutho eyahlukeneyo, ngaloo ndlela sineempawu ezahlukeneyo. Isinyithi kunye nentsimbi sesona sisinyithi sisetyenziswa kakhulu kushishino, kwaye isakhiwo sentsimbi sikwayeyona inzima, ngoko ke kukho iintlobo ngeentlobo zeenkqubo zokunyanga ubushushu bentsimbi.

Unyango lobushushu ngokubanzi kukufudumeza iyonke indawo yokusebenza, ize ipholiswe ngesantya esifanelekileyo, ukuze kufunyanwe ulungelelwaniso olufunekayo lwe-metallurgical, ukuze kutshintshwe iipropati zayo zoomatshini zenkqubo yonyango lobushushu besinyithi. Unyango lobushushu ngokubanzi lwentsimbi oluyi-annealing, oluyi-normalizing, oluyi-quenching kunye noluyi-tempering iinkqubo ezine ezisisiseko.

Inkqubo ithetha:

I-Annealing yi-workpiece efudunyezwa kubushushu obufanelekileyo, ngokwezinto eziphathekayo kunye nobukhulu be-workpiece kusetyenziswa ixesha elahlukileyo lokubamba, ize ipholiswe kancinci kancinci, injongo kukwenza ulungiselelo lwangaphakathi lwesinyithi lufikelele okanye lusondele kwimeko yokulingana, ukuze kufumaneke ukusebenza kakuhle kwenkqubo kunye nokusebenza, okanye ukuze kucinywe ngakumbi ulungiselelo lokulungiselela.

Ukulungisa izinto kukuba umsebenzi ufudunyezwa kubushushu obufanelekileyo emva kokuba upholile emoyeni, isiphumo sokulungisa izinto sifana nokulungisa izinto, kodwa ukuze kubekho ulungelelwaniso oluhle, oluhlala lusetyenziswa ukuphucula ukusebenza kokusika kwezinto, kodwa ngamanye amaxesha lusetyenziswa kwezinye zeendawo ezingafunekiyo njengonyango lokugqibela lobushushu.

Ukucima kushushu kwaye kugqunywe ngamanzi, kwioyile okanye kwezinye iityuwa ezingaphiliyo, kwizisombululo zamanzi eziphilayo kunye nakwezinye iindlela zokucima ukuze kuphole ngokukhawuleza. Emva kokucima, iindawo zentsimbi ziba nzima, kodwa kwangaxeshanye ziba buthathaka, ukuze kupheliswe ubuthathaka ngexesha elifanelekileyo, kufuneka kufudunyezwe ngexesha elifanelekileyo.

Ukuze kuncitshiswe ukuphuka kweendawo zentsimbi, iindawo zentsimbi ezicinyiweyo kubushushu obufanelekileyo obuphezulu kunobushushu begumbi kwaye zibe ngaphantsi kwama-650 ℃ ixesha elide lokufakelwa, zize zipholiswe, le nkqubo ibizwa ngokuba yi-tempering. Ukuqhoboshela, ukuqhelelanisa, ukucima, ukufudumala lunyango lobushushu olupheleleyo "kwimililo emine", apho ukucima kunye nokufudumala kunxulumene ngokusondeleyo, kusetyenziswa rhoqo kunye, enye iyimfuneko. "Umlilo kane" kunye nobushushu bokufudumala kunye nendlela yokupholisa eyahlukeneyo, kwaye kwavela inkqubo eyahlukileyo yonyango lobushushu. Ukuze kufunyanwe inqanaba elithile lamandla kunye nokuqina, ukucima kunye nokufudumala kubushushu obuphezulu kudityaniswe nenkqubo, eyaziwa ngokuba yi-tempering. Emva kokuba ii-alloys ezithile zicinyiwe ukwenza isisombululo esiqinileyo esiqinileyo, zigcinwa kubushushu begumbi okanye kubushushu obuphezulu obufanelekileyo ixesha elide ukuze kuphuculwe ubunzima, amandla, okanye imagnetism yombane ye-alloy. Inkqubo enjalo yonyango lobushushu ibizwa ngokuba lunyango lokuguga.

Ukulungiswa koxinzelelo kunye nonyango lobushushu ngokufanelekileyo nangokusondeleyo zidityaniswe ukuze kufezwe, ukuze i-workpiece ifumane amandla amahle kakhulu, ubulukhuni ngendlela eyaziwa ngokuba yi-deformation heat treatment; kwindawo engaphantsi koxinzelelo okanye kwi-vacuum treatment yobushushu eyaziwa ngokuba yi-vacuum heat treatment, engenza ukuba i-workpiece ingaxilisi, ingasusi i-carburize, igcine umphezulu we-workpiece emva konyango, iphucule ukusebenza kwe-workpiece, kodwa ikwasebenzisa i-osmotic agent yonyango lobushushu beekhemikhali.

Unyango lobushushu obuphezulu kukufudumeza kuphela umaleko wobuso besixhobo sokusebenza ukuze kutshintshwe iimpawu zoomatshini zomaleko wobuso benkqubo yonyango lobushushu besinyithi. Ukuze kufudunyezwe kuphela umaleko wobuso besixhobo sokusebenza ngaphandle kokudluliselwa kobushushu obuninzi kwindawo yokusebenza, ukusetyenziswa komthombo wobushushu kufuneka kube noxinano olukhulu lwamandla, oko kukuthi, kwindawo yeyunithi yesixhobo sokusebenza ukuze kunikwe amandla obushushu amakhulu, ukuze umaleko wobuso besixhobo sokusebenza okanye obekwe kwindawo ethile ube nexesha elifutshane okanye ngokukhawuleza ukufikelela kubushushu obuphezulu. Unyango lobushushu obuphezulu lweendlela eziphambili zokucima ilangatye kunye nonyango lobushushu bokungenisa, imithombo yobushushu esetyenziswa rhoqo efana ne-oxyacetylene okanye i-oxypropane flame, i-induction current, i-laser kunye ne-electron beam.

Unyango lobushushu bekhemikhali yinkqubo yonyango lobushushu besinyithi ngokutshintsha ulwakhiwo lwekhemikhali, ulungelelwaniso kunye neempawu zomaleko womphezulu wesixhobo somsebenzi. Unyango lobushushu bekhemikhali lwahlukile kunyango lobushushu bomphezulu kuba olokuqala lutshintsha ulwakhiwo lwekhemikhali lomaleko womphezulu wesixhobo somsebenzi. Unyango lobushushu bekhemikhali lubekwa kwisixhobo somsebenzi esiqulethe ikhabhoni, ityuwa okanye ezinye izinto zokudibanisa zesixhobo (igesi, ulwelo, i-solid) ekufudumaleni, ekugqumeni ixesha elide, ukuze umaleko womphezulu wesixhobo somsebenzi ungene kwikhabhoni, initrogen, iboron kunye ne-chromium kunye nezinye izinto. Emva kokungena kwezinto, kwaye ngamanye amaxesha ezinye iinkqubo zonyango lobushushu ezifana nokucima kunye nokushisa. Iindlela eziphambili zonyango lobushushu bekhemikhali kukufaka i-carburizing, i-nitriding, ukungena kwesinyithi.

Unyango lobushushu yenye yeenkqubo ezibalulekileyo kwinkqubo yokwenziwa kweendawo zoomatshini kunye neenkuni. Ngokubanzi, inokuqinisekisa kwaye iphucule iipropati ezahlukeneyo zomsebenzi, ezinje ngokumelana nokuguguleka, ukumelana nokugqwala. Ingaphucula nokulungelelaniswa kwemeko yokungabi nanto kunye noxinzelelo, ukuze kube lula ukucutshungulwa okubandayo nokushisa.

Umzekelo: intsimbi emhlophe emva kwexesha elide i-annealing treatment ingafumaneka intsimbi ethambileyo, iphucule i-plasticity; iigiya ezinenkqubo efanelekileyo yonyango lobushushu, ubomi benkonzo bunokuba ngaphezu kokungabi njalo iigiya eziphathwa ngobushushu amaxesha amaninzi okanye amaninzi; ukongeza, intsimbi yekhabhoni engabizi kakhulu ngokungena kwezinto ezithile ze-alloying ine-alloy steel ebiza kakhulu, ingathatha indawo yentsimbi ethile engatshiyo, intsimbi engatyiwayo; ii-molds kunye nee-dies phantse zonke kufuneka zidlule kunyango lobushushu. Zingasetyenziswa kuphela emva konyango lobushushu.

Iindlela ezongezelelweyo

I. Iintlobo zokutsalela

I-Annealing yinkqubo yonyango lobushushu apho umsebenzi ufudunyezwa ukuya kubushushu obufanelekileyo, ugcinwe ixesha elithile, uze upholiswe kancinci.

Kukho iintlobo ezininzi zenkqubo yokubopha intsimbi, ngokwendlela yobushushu bokufudumeza, ingahlulwahlulwa ibe ziindidi ezimbini: enye ikwiqondo lobushushu elibalulekileyo (Ac1 okanye Ac3) ngaphezulu kwe-annealing, eyaziwa ngokuba yi-phase change recrystallization annealing, equka i-complete annealing, i-incomplete annealing, i-spheroidal annealing kunye ne-diffusion annealing (homogenization annealing), njl.; enye ingaphantsi kobushushu obubalulekileyo be-annealing, equka i-recrystallization annealing kunye ne-de-stressing annealing, njl. Ngokwendlela yokupholisa, i-annealing ingahlulwahlulwa ibe yi-isothermal annealing kunye ne-continuous cooling annealing.

1, ukuqhoboshela okupheleleyo kunye nokuqhoboshela okungabonakaliyo

I-annealing epheleleyo, ekwaziwa ngokuba yi-recrystallization annealing, ekwabizwa ngokuba yi-annealing, yintsimbi okanye intsimbi efudunyezwa kwi-Ac3 ngaphezulu kwama-20 ~ 30 ℃, i-insulation ende ngokwaneleyo ukwenza umbutho uqine ngokupheleleyo emva kokupholisa kancinci, ukuze kufunyanwe ulungelelwaniso oluphantse lube yi-equilibrium yenkqubo yonyango lobushushu. Le annealing isetyenziselwa ikakhulu ukwakheka kwe-sub-eutectic yee-castings ezahlukeneyo ze-carbon kunye ne-alloy steel, ii-forgings kunye neeprofayili eziqengqelekayo ezishushu, kwaye ngamanye amaxesha ikwasetyenziselwa izakhiwo eziweldiweyo. Ngokuqhelekileyo idla ngokuba yi-workpiece ende yonyango lokugqibela lobushushu, okanye njengonyango lwangaphambi kobushushu kwezinye izinto zokusebenza.

2, ukuqhoboshela ibhola

I-spheroidal annealing isetyenziswa kakhulu kwintsimbi yekhabhoni egqithisileyo kunye nentsimbi yezixhobo ze-alloy (njengokwenziwa kwezixhobo ezigobileyo, iigeyiji, iimold kunye needayi ezisetyenziswa kwintsimbi). Injongo yayo ephambili kukunciphisa ubulukhuni, ukuphucula ukusebenza kwemishini, kunye nokulungiselela ukucima kwixesha elizayo.

3, ukuncedisa ekunciphiseni uxinezeleko

I-annealing yokunciphisa uxinzelelo, ekwaziwa ngokuba yi-annealing yobushushu obuphantsi (okanye i-tempering yobushushu obuphezulu), le annealing isetyenziselwa kakhulu ukususa ii-castings, ii-forgings, ii-weldments, iindawo ezigoqwe ngobushushu, iindawo ezitsalwa kubanda kunye nolunye uxinzelelo olushiyekileyo. Ukuba olu xinzelelo alususwanga, luya kubangela intsimbi emva kwexesha elithile, okanye kwinkqubo yokusika elandelayo ivelise ukuguquka okanye imifantu.

4. Ukufunxa okungaphelelanga kukufunxa intsimbi kwi-Ac1 ~ Ac3 (intsimbi engaphantsi kwe-eutectic) okanye kwi-Ac1 ~ ACcm (intsimbi engaphaya kwe-eutectic) phakathi kokugcinwa kobushushu kunye nokupholisa kancinci ukuze kufunyanwe ulungelelwaniso oluphantse lulungelelaniswe lwenkqubo yonyango lobushushu.

II.ukucima, eyona ndlela yokupholisa esetyenziswa kakhulu yityuwa, amanzi kunye neoyile.

Ukucima amanzi anetyuwa kwisixhobo sokusebenza, kulula ukufumana ubunzima obuphezulu kunye nomphezulu ogudileyo, akukho lula ukuvelisa ukucima, akukho ndawo ithambileyo iqinileyo, kodwa kulula ukuyenza. Ukuguqulwa kwesixhobo sokusebenza kunzulu, kwaye kuyaqhekeka. Ukusetyenziswa kweoyile njengendlela yokucima kufanelekile kuphela ukuzinza kwe-austenite epholileyo kakhulu kwintsimbi ethile ye-alloy okanye ubungakanani obuncinci besixhobo sokusebenza se-carbon steel.

III.injongo yokushisa intsimbi

1, ukunciphisa ukubuthathaka, ukususa okanye ukunciphisa uxinzelelo lwangaphakathi, ukucima intsimbi kukho uxinzelelo olukhulu lwangaphakathi kunye nokubuthathaka, njengoko ukungalungiswa ngexesha elifanelekileyo kuya kwenza intsimbi iguquke okanye iqhekeke.

2, ukuze ufumane iipropati zoomatshini ezifunekayo zesixhobo somsebenzi, isixhobo somsebenzi emva kokucima ubulukhuni obuphezulu kunye nokuqhekeka, ukuze kuhlangatyezwane neemfuno zeepropati ezahlukeneyo zezixhobo zomsebenzi ezahlukeneyo, ungalungisa ubulukhuni ngokusebenzisa i-tempering efanelekileyo ukuze unciphise ubulukhuni bobulukhuni obufunekayo, i-plasticity.

3, Zinzisa ubungakanani besixhobo somsebenzi

4, kuba ukuthambisa intsimbi ethile ye-alloy kunzima, xa i-annealing isetyenziswa rhoqo emva kokutshisa (okanye ukuqheleka) emva kobushushu obuphezulu, ukuze i-carbon dioxide yentsimbi idibane ngokufanelekileyo, ubunzima buya kuncipha, ukuze kube lula ukusika kunye nokucutshungulwa.

Iingcamango ezongezelelweyo

1, ukuqhoboshela: kubhekisa kwizinto zesinyithi ezifudunyezwa kubushushu obufanelekileyo, zigcinwe ixesha elithile, zize emva koko zipholiswe kancinci yinkqubo yonyango lobushushu. Iinkqubo eziqhelekileyo zokuqhoboshela zezi: ukuqhoboshela kwakhona ukuqhoboshela, ukuqhoboshela koxinzelelo, ukuqhoboshela okuphekiweyo, ukuqhoboshela okupheleleyo, njl.njl. Injongo yokuqhoboshela: ngokuyintloko ukunciphisa ubulukhuni bezinto zesinyithi, ukuphucula i-plasticity, ukuze kube lula ukusika okanye ukwenza uxinzelelo, ukunciphisa uxinzelelo olushiyekileyo, ukuphucula ulungelelwaniso kunye nokwakheka kwe-homogenization, okanye unyango lokugqibela lobushushu ukwenza umbutho ulungele.

2, ukulungisa: kubhekisa kwintsimbi okanye intsimbi eshushu okanye (intsimbi kwindawo ebalulekileyo yobushushu) engentla, 30 ~ 50 ℃ ukugcina ixesha elifanelekileyo, ukupholisa kwinkqubo yonyango lobushushu bomoya opholileyo. Injongo yokwenza izinto zibe zintsha: ikakhulu ukuphucula iipropati zoomatshini zentsimbi enekhabhoni ephantsi, ukuphucula ukusika kunye nokusebenza kakuhle, ukucocwa kweenkozo, ukususa iziphene zombutho, ukuze unyango lobushushu lokugqibela lulungiselele umbutho.

3, ukucima: kubhekisa kwintsimbi efudunyezwa kwi-Ac3 okanye kwi-Ac1 (intsimbi ephantsi kweqondo lobushushu elibalulekileyo) ngaphezu kobushushu obuthile, igcina ixesha elithile, ize ifikelele kwinqanaba elifanelekileyo lokupholisa, ukuze ifumane ulungelelwaniso lwe-martensite (okanye i-bainite) lwenkqubo yonyango lobushushu. Iinkqubo eziqhelekileyo zokucima kukucima okuphakathi okukodwa, ukucima okuphakathi okubini, ukucima i-martensite, ukucima i-bainite isothermal, ukucima umphezulu kunye nokucima kwendawo. Injongo yokucima: ukuze iindawo zentsimbi zifumane ulungelelwaniso olufunekayo lwe-martensitic, ziphucule ubulukhuni bomsebenzi, amandla kunye nokumelana nokukrala, ukuze unyango lokugqibela lobushushu lwenze amalungiselelo afanelekileyo ombutho.

4, ukufudumala: kubhekisa kwintsimbi eqinileyo, emva koko ifudunyezwe ukuya kubushushu obungaphantsi kwe-Ac1, ixesha lokubamba, ize ipholiswe ukuya kubushushu begumbi. Iinkqubo eziqhelekileyo zokufudumala zezi: ukufudumala okuphantsi kobushushu, ukufudumala okuphakathi, ukufudumala okuphezulu kunye nokufudumala okuninzi.

Injongo yokunciphisa: ikakhulu kukususa uxinzelelo oluveliswa yintsimbi ekucimeni, ukuze intsimbi ibe nobunzima obuphezulu kunye nokumelana nokuguguleka, kwaye ibe ne-plasticity kunye nokuqina okufunekayo.

5, ukufudumala: kubhekisa kwintsimbi okanye kwintsimbi yokucima kunye nokufudumala okuphezulu kwenkqubo yonyango lobushushu obudibeneyo. Kusetyenziswa kunyango lokufudumala lwentsimbi ebizwa ngokuba yintsimbi efudumeleyo. Ngokubanzi ibhekisa kwintsimbi yesakhiwo sekhabhoni ephakathi kunye nentsimbi yesakhiwo se-carbon alloy ephakathi.

6, i-carburizing: i-carburizing yinkqubo yokwenza ii-athomu zekhabhoni zingene kumaleko womphezulu wentsimbi. Kwakhona kukwenza i-workpiece yentsimbi ekhabhoni ephantsi ibe nomaleko womphezulu wentsimbi ekhabhoni ephezulu, uze emva koko ucime kwaye ufudumale ubushushu obuphantsi, ukuze umaleko womphezulu we-workpiece ube nobunzima obuphezulu kunye nokumelana nokuguguleka, ngelixa inxalenye esembindini ye-workpiece isagcina ubulukhuni kunye ne-plasticity yentsimbi ekhabhoni ephantsi.

Indlela yokufunxa umoya

Ngenxa yokuba imisebenzi yokufudumeza nokupholisa yezixhobo zokusebenza zesinyithi ifuna amanyathelo alishumi elinesibini okanye amashumi amabini ukuze igqitywe. Ezi zenzo zenziwa ngaphakathi kwesithando sonyango lobushushu lwe-vacuum, umqhubi akanakusondela, ngoko ke inqanaba lokuzenzekela kwesithando sonyango lobushushu lwe-vacuum kufuneka libe phezulu. Kwangaxeshanye, ezinye izenzo, ezifana nokufudumeza nokubamba isiphelo senkqubo yokucima i-metal workpiece kufuneka zibe ziintshukumo ezintandathu, ezisixhenxe kwaye zigqitywe kwimizuzwana eli-15. Ezi meko zikhawulezayo zokugqiba izenzo ezininzi, kulula ukubangela uvalo lomqhubi kwaye zenze ukuba angasebenzi kakuhle. Ke ngoko, kuphela inqanaba eliphezulu lokuzenzekela elinokuba lulungelelwaniso oluchanekileyo nolufike ngexesha ngokuhambelana nenkqubo.

Unyango lobushushu be-vacuum kwiindawo zesinyithi lwenziwa kwisithando somoya esivaliweyo, ukutywinwa okungqongqo kwe-vacuum kwaziwa kakuhle. Ke ngoko, ukuze kufunyanwe kwaye kulandelwe izinga lokuqala lokuvuza komoya wesithando, ukuqinisekisa ukuba i-vacuum esebenzayo yesithando somoya, ukuqinisekisa umgangatho weendawo, unyango lobushushu be-vacuum lubaluleke kakhulu. Ngoko ke, umba ophambili wesithando somoya kukuba nesakhiwo esithembekileyo sokutywinwa kwe-vacuum. Ukuze kuqinisekiswe ukusebenza kwe-vacuum yesithando somoya, uyilo lwesakhiwo sesithando somoya kufuneka lulandele umgaqo osisiseko, oko kukuthi, umzimba wesithando kufuneka usebenzise i-welding engangenisi igesi, ngelixa umzimba wesithando kufuneka uvule okanye ungawuvuli umngxuma kancinci kangangoko, unciphise okanye uphephe ukusetyenziswa kwesakhiwo sokutywinwa esinamandla, ukuze kuncitshiswe ithuba lokuvuza kwe-vacuum. Izixhobo zomzimba wesithando somoya, ezinje ngee-electrode ezipholiswe ngamanzi, isixhobo sokuthumela ngaphandle se-thermocouple kufuneka senzelwe ukuvala isakhiwo.

Uninzi lwezinto zokufudumeza kunye nokwambathisa zingasetyenziswa kuphela phantsi kwe-vacuum. Unyango lobushushu lwe-vacuum, ukufudumeza kunye nokwambathisa ubushushu, i-lining ye-thermal insulation ikwi-vacuum kwaye isebenza ngobushushu obuphezulu, ngoko ke ezi zinto zibeka phambili ukumelana nobushushu obuphezulu, iziphumo zemitha, ukuhanjiswa kobushushu kunye nezinye iimfuno. Iimfuneko zokuxhathisa i-oxidation aziphezulu. Ke ngoko, i-vacuum heat treatment furnace isetyenziswa kakhulu kwi-tantalum, tungsten, molybdenum kunye ne-graphite kwizixhobo zokufudumeza kunye nokwambathisa ubushushu. Ezi zinto kulula kakhulu ukuzixuba kwimeko yomoya, ke ngoko, i-heat treatment eqhelekileyo ayinakusebenzisa ezi zinto zokufudumeza kunye nokwambathisa.

Isixhobo esipholisiweyo ngamanzi: igobolondo lesithando sokucoca ubushushu se-vacuum, isigqubuthelo sesithando somlilo, izinto zokufudumeza ngombane, ii-electrode ezipholisiweyo ngamanzi, ucango oluphakathi lwe-vacuum heat insulation kunye nezinye izinto, zikwi-vacuum, phantsi kwemeko yomsebenzi wobushushu. Ukusebenza phantsi kweemeko ezingathandekiyo kangako, kufuneka kuqinisekiswe ukuba ulwakhiwo lwecandelo ngalinye alunakonakala okanye lonakele, kwaye isitywino sesithando somlilo asishushu kakhulu okanye sitshiswe. Ke ngoko, icandelo ngalinye kufuneka limiselwe ngokweemeko ezahlukeneyo izixhobo zokupholisa amanzi ukuqinisekisa ukuba isithando sokucoca ubushushu se-vacuum sinokusebenza ngokuqhelekileyo kwaye sibe nobomi obaneleyo bokusetyenziswa.

Ukusetyenziswa kwesikhongozeli se-vacuum esiphantsi-voltage ephezulu: isitya se-vacuum, xa i-vacuum vacuum degree ye-lxlo-1 torr range ezimbalwa, isitya se-vacuum somqhubi onikwe amandla kwi-voltage ephezulu, siya kuvelisa i-glow discharge. Kwisithando sonyango lobushushu be-vacuum, i-arc discharge enzima iya kutshisa i-element yokufudumeza yombane, umaleko we-insulation, nto leyo ebangela iingozi ezinkulu kunye nelahleko. Ke ngoko, i-vacuum heat treatment electric heat element voltage yokusebenza ngokubanzi ayidluli kwi-80 ukuya kwi-100 volts. Kwangaxeshanye, kuyilo lwesakhiwo se-element yokufudumeza yombane, amanyathelo asebenzayo anjengokuzama ukuphepha ukuba nencam yeendawo, isithuba se-electrode phakathi kwee-electrode asinakuba mncinci kakhulu, ukuze kuthintelwe ukuveliswa kwe-glow discharge okanye i-arc discharge.

Ukunciphisa

Ngokweemfuno ezahlukeneyo zokusebenza kwesixhobo somsebenzi, ngokweeqondo zobushushu ezahlukeneyo, singahlulwa sibe ziintlobo ezilandelayo zokushisa:

(a) ubushushu obuphantsi (ii-degrees ezili-150-250)

Ubushushu obuphantsi bombutho ophumayo kwi-martensite eqinisiweyo. Injongo yayo kukugcina ubunzima obuphezulu kunye nokumelana okuphezulu kokuguguleka kwentsimbi ecinyiweyo phantsi kwesiseko sokunciphisa uxinzelelo lwangaphakathi kunye nokuqhekeka kwayo, ukuze kuthintelwe ukuqhekeka okanye ukonakala kwangaphambi kwexesha ngexesha lokusetyenziswa. Isetyenziswa kakhulu kwizixhobo ezahlukeneyo zokusika ezinekhabhoni ephezulu, iigeyiji, iidayi ezitsalwa ngokubandayo, iibheringi eziqengqelekayo kunye neendawo ezinekhabhoni, njl.njl., emva kobunzima bokuqinisisa ngokubanzi yi-HRC58-64.

(ii) ubushushu obuphakathi (ii-degrees ezingama-250-500)

Ulungelelwaniso lobushushu obuphakathi lomzimba we-quartz oqinisiweyo. Injongo yalo kukufumana amandla aphezulu emveliso, umda we-elastic kunye nokuqina okuphezulu. Ke ngoko, isetyenziselwa ikakhulu iintlobo ngeentlobo zemithombo kunye nokulungiswa kwesikhunta somsebenzi oshushu, ubunzima bokuqinisisa ngokubanzi yi-HRC35-50.

(C) ubushushu obuphezulu (500-650 degrees)

Ukufudumala okuphezulu kombutho weSohnite efudumeleyo. Ukucima okuqhelekileyo kunye nokufudumala okuphezulu kobushushu obuphezulu unyango oludibeneyo lobushushu olwaziwa ngokuba yi-tempering treatment, injongo yalo kukufumana amandla, ubulukhuni kunye ne-plasticity, ubulukhuni ziimpawu ezingcono zoomatshini ngokubanzi. Ke ngoko, isetyenziswa kakhulu kwiimoto, iitrektara, izixhobo zoomatshini kunye nezinye iindawo ezibalulekileyo zesakhiwo, ezifana neentonga zokudibanisa, iibholiti, iigiya kunye neeshafti. Ubulukhuni emva kokufudumala ngokubanzi yi-HB200-330.

Ukuthintela ukuguqulwa kobume

Izizathu zokuguqulwa kwesikhunta ngendlela echanekileyo zidla ngokuba nzima, kodwa siyakwazi nje ukuyiqonda imithetho yayo yokuguqulwa kwesikhunta, sihlalutye izizathu zayo, sisebenzisa iindlela ezahlukeneyo zokuthintela ukuguqulwa kwesikhunta, siyakwazi ukunciphisa, kodwa sikwazi nokulawula. Ngokubanzi, unyango lobushushu lokuguqulwa kwesikhunta ngendlela echanekileyo lunokuthatha ezi ndlela zilandelayo zokuthintela.

(1) Ukukhetha izinto ezifanelekileyo. Iinkuni ezintsonkothileyo ezichanekileyo kufuneka zikhethwe njengezinto ezifanelekileyo ze-microdeformation mold steel (ezifana nentsimbi yokucima umoya), ukwahlulwahlulwa kwe-carbide yentsimbi enzulu ye-mold kufuneka kube yinto efanelekileyo yokwenza kunye nokulungisa ubushushu, intsimbi enkulu ye-mold ayinakwenziwa ingaba sisisombululo esiqinileyo sonyango lobushushu oluphindwe kabini.

(2) Uyilo lwesakhiwo se-mould kufuneka lube nolwazelelelo, ubukhulu abufanele bube nomahluko kakhulu, imo kufuneka ibe nomlinganiselo ofanayo, ukuze i-mould enkulu ikwazi ukujikajika kakuhle, isibonelelo sokucubungula esibekelwe bucala, kwi-mould ezinkulu, ezichanekileyo nezintsonkothileyo zingasetyenziswa kudibaniso lwezakhiwo.

(3) Ukubumba okuchanekileyo nokuntsonkothileyo kufuneka kusetyenziswe ngaphambi kobushushu ukuze kupheliswe uxinzelelo olushiyekileyo oluvela kwinkqubo yokwenziwa kwemishini.

(4) Ukukhetha okufanelekileyo kobushushu bokufudumeza, lawula isantya sokufudumeza, ukuze kube nokuchaneka kokubumba okuntsonkothileyo, kungathatha ukufudumeza okucothayo, ukufudumeza kwangaphambili kunye nezinye iindlela zokufudumeza ezilinganayo ukunciphisa ukuguqulwa konyango lobushushu bokubumba.

(5) Phantsi kwesiseko sokuqinisekisa ubulukhuni bokubumba, zama ukusebenzisa inkqubo yokupholisa ngaphambi kokupholisa, ukucima ukupholisa okulinganisiweyo okanye inkqubo yokucima ubushushu.

(6) Ukuze ufumane iimolds ezichanekileyo nezintsonkothileyo, phantsi kweemeko ezivumelekileyo, zama ukusebenzisa i-vacuum heating quenching kunye ne-deep cooling treatment emva kokucima.

(7) Ukuze ufumane ezinye iimbombo ezichanekileyo nezintsonkothileyo, unyango lwangaphambi kobushushu, unyango lobushushu obudala, unyango lobushushu olusebenzisa i-nitriding ukulawula ukuchaneka kwembombo.

(8) Ekulungiseni imingxuma yesanti yesikhunta, ukubola, ukuguguleka nezinye iziphene, ukusetyenziswa komatshini wokuwelda obandayo kunye nezinye iziphumo zobushushu zezixhobo zokulungisa ukuthintela inkqubo yokulungisa yokuguquka.

Ukongeza, ukusebenza ngokuchanekileyo kwenkqubo yokunyanga ubushushu (njengokufaka imingxuma, imingxuma ebotshelelweyo, ukulungiswa koomatshini, iindlela ezifanelekileyo zokufudumeza, ukhetho oluchanekileyo lwendlela yokuphola yesikhunta kunye necala lokuhamba kwindawo yokuphola, njl.njl.) kunye nenkqubo efanelekileyo yokunyanga ubushushu bokuthomalalisa ukunciphisa ukuguquguquka kokuchaneka kwaye isikhunta esintsonkothileyo nazo ziyindlela ezisebenzayo.

Ukucima umphezulu kunye nonyango lobushushu obuthambileyo ludla ngokwenziwa ngokufudumeza ngokungenisa okanye ukufudumeza ilangabi. Iiparameter eziphambili zobugcisa bubulukhuni bomphezulu, ubulukhuni bendawo kunye nobunzulu bomaleko obuqinileyo obusebenzayo. Uvavanyo lobunzima lungasetyenziswa ngumvavanyi wobulukhuni beVickers, lungasetyenziswa nakwiRockwell okanye ngumvavanyi wobulukhuni beRockwell yomphezulu. Ukukhetha amandla ovavanyo (isikali) kunxulumene nobunzulu bomaleko oqinileyo osebenzayo kunye nobunzima bomphezulu wesixhobo somsebenzi. Zintathu iintlobo zabavavanyi bobulukhuni ezibandakanyekayo apha.

Okokuqala, i-Vickers hardness tester yindlela ebalulekileyo yokuvavanya ubulukhuni bomphezulu wezinto zokusebenza eziphathwa ngobushushu, inokukhethwa ukusuka kwi-0.5 ukuya kwi-100kg yamandla ovavanyo, ivavanye umaleko wokuqina komphezulu obhityileyo njengobukhulu obuyi-0.05mm, kwaye ukuchaneka kwayo kuphezulu, kwaye inokwahlula umahluko omncinci kubulukhuni bomphezulu wezinto zokusebenza eziphathwa ngobushushu. Ukongeza, ubunzulu bomaleko oqinisiweyo osebenzayo kufuneka bubonwe ngumvavanyi wobunzima beVickers, ngoko ke ekucwangcisweni konyango lobushushu bomphezulu okanye inani elikhulu leeyunithi ezisebenzisa i-surface heat treatment workpiece, exhotyiswe nge-Vickers hardness tester iyafuneka.

Okwesibini, umvavanyi wobulukhuni beRockwell kumphezulu ufanelekile kakhulu ukuvavanya ubulukhuni be-workpiece eqinileyo kumphezulu, umvavanyi wobulukhuni beRockwell kumphezulu unezikali ezintathu onokukhetha kuzo. Ungavavanya ubunzulu bobulukhuni obusebenzayo obungaphezulu kwe-0.1mm ye-workpiece eyahlukeneyo yokuqina komphezulu. Nangona ukuchaneka komvavanyi wobulukhuni beRockwell kumphezulu kungabi phezulu njengomvavanyi wobulukhuni beVickers, kodwa njengolawulo lomgangatho wesityalo sonyango lobushushu kunye neendlela zokuhlola ezifanelekileyo zokufumanisa, ukwazile ukuhlangabezana neemfuno. Ngaphezu koko, ikwanayo nokusebenza okulula, okulula ukuyisebenzisa, ixabiso eliphantsi, ukulinganisa ngokukhawuleza, inokufunda ngokuthe ngqo ixabiso lobulukhuni kunye nezinye iimpawu, ukusetyenziswa komvavanyi wobulukhuni beRockwell kumphezulu kunokuba yibhetshi ye-workpiece yonyango lobushushu kumphezulu yovavanyo olukhawulezayo nolungatshabalalisiyo lweqhekeza ngeqhekeza. Oku kubalulekile kwisityalo sokwenza isinyithi kunye noomatshini.

Okwesithathu, xa umaleko oqinisiweyo wonyango lobushushu bomphezulu utyebile, ungasebenzisa iRockwell hardness tester. Xa ubukhulu bomaleko oqinisiweyo wonyango lobushushu buyi-0.4 ~ 0.8mm, ungasebenzisa i-HRA scale, xa ubukhulu bomaleko oqinisiweyo buyi-0.8mm, ungasebenzisa i-HRC scale.

Iintlobo ezintathu zexabiso lobulukhuni zeVickers, Rockwell kunye nomphezulu weRockwell zinokuguqulwa ngokulula zibe zezinye, ziguqulwe zibe zezomgangatho, imizobo okanye umsebenzisi afune ixabiso lobulukhuni. Iitafile zokuguqulwa ezihambelanayo zinikwe kwi-ISO esemgangathweni yamazwe ngamazwe, i-ASTM esemgangathweni yaseMelika kunye ne-GB/T esemgangathweni yaseTshayina.

Ukuqina kwendawo

Iinxalenye ukuba zifuna ubulukhuni bendawo obuphezulu, obufumanekayo bokufudumeza kunye nezinye iindlela zonyango lobushushu bokucima ubushushu bendawo, ezo ndawo zihlala kufuneka ziphawule indawo yonyango lobushushu bokucima ubushushu bendawo kunye nexabiso lobulukhuni bendawo kwimizobo. Uvavanyo lobulukhuni lweendawo kufuneka lwenziwe kwindawo ekhethiweyo. Izixhobo zovavanyo lobulukhuni zingasetyenziswa kwi-Rockwell hardness tester, uvavanyo lwexabiso lobulukhuni be-HRC, njengonyango lobushushu umaleko wokuqina awunzulu, ungasetyenziswa kumphezulu we-Rockwell hardness tester, uvavanyo lwexabiso lobulukhuni be-HRN.

Unyango lobushushu bekhemikhali

Unyango lobushushu bekhemikhali kukwenza umphezulu wento yokusebenza ungene kwi-athomu enye okanye ezininzi zeekhemikhali, ukuze kutshintshwe ukwakheka kweekhemikhali, ulungelelwaniso kunye nokusebenza komphezulu wento yokusebenza. Emva kokucima kunye nokushisa okuphantsi, umphezulu wento yokusebenza uba nobunzima obuphezulu, ukumelana nokuguguleka kunye namandla okudinwa, ngelixa umongo wento yokusebenza unamandla aphezulu.

Ngokwale ingentla, ukufunyanwa nokurekhoda ubushushu kwinkqubo yonyango lobushushu kubaluleke kakhulu, kwaye ulawulo olubi lobushushu lunempembelelo enkulu kwimveliso. Ke ngoko, ukufunyanwa kobushushu kubaluleke kakhulu, umkhwa wobushushu kuyo yonke inkqubo nawo ubaluleke kakhulu, nto leyo ebangela ukuba inkqubo yonyango lobushushu kufuneka irekhodwe kutshintsho lobushushu, inokwenza kube lula uhlalutyo lwedatha kwixesha elizayo, kodwa ikwabone ukuba loluphi ixesha ubushushu obungahlangabezani neemfuno. Oku kuya kudlala indima enkulu kakhulu ekuphuculeni unyango lobushushu kwixesha elizayo.

Iinkqubo zokusebenza

1. Coca indawo yokusebenza, jonga ukuba umbane, izixhobo zokulinganisa kunye neeswitshi ezahlukeneyo ziqhelekile na, kwaye nokuba umthombo wamanzi ugudile na.

2. Abaqhubi kufuneka banxibe izixhobo zokukhusela abasebenzi ezifanelekileyo, kungenjalo kuya kuba yingozi.

3, vula iswitshi yokudlulisa amandla olawulo jikelele, ngokweemfuno zobugcisa zamacandelo ahlelwe ngokwemigangatho yezixhobo zokunyuka nokuwa kobushushu, ukuze kwandiswe ubomi bezixhobo kunye nezixhobo zingasebenzi.

4, ukuze kunikelwe ingqalelo kubushushu besithando sonyango lobushushu kunye nolawulo lwesantya sebhanti ye-mesh, kunokukwazi ukuqonda imigangatho yobushushu efunekayo kwizinto ezahlukeneyo, ukuqinisekisa ubulukhuni bento yokusebenza kunye nokuthe tye komphezulu kunye nomaleko we-oxidation, kwaye kwenze umsebenzi olungileyo wokhuseleko.

5, Ukuze kunikelwe ingqalelo kubushushu besithando somlilo kunye nesantya sebhanti ye-mesh, vula umoya wokukhupha umoya, ukuze i-workpiece emva kokupholisa ihlangabezane neemfuno zomgangatho.

6, emsebenzini kufuneka unamathele kwisithuba.

7, ukumisela izixhobo zomlilo ezifunekayo, kunye nokuqhelana neendlela zokusetyenziswa kunye nokugcinwa kwazo.

8. Xa simisa umatshini, kufuneka sijonge ukuba zonke iiswitshi zolawulo zikwimeko yokungasebenzi, size emva koko sivale iswitshi yokudlulisa yonke indawo.

Ubushushu obugqithisileyo

Ukusuka emlonyeni orhabaxa wezixhobo zerola, iindawo zokuthwala zinokubonwa emva kokucima ubushushu besakhiwo se-microstructure. Kodwa ukuze kuchongwe inqanaba elichanekileyo lobushushu kufuneka kujongwe isakhiwo se-microstructure. Ukuba kwi-GCr15 steel quenching organization xa ibukeka njenge-coarse needle martensite, yi-quenching overheating organization. Isizathu sokwenziwa kokucima ubushushu bobushushu sinokuba phezulu kakhulu okanye ukufudumeza kwaye ixesha lokubamba lide kakhulu ngenxa yoluhlu olupheleleyo lobushushu; kusenokuba kungenxa yolungiselelo lokuqala lwe-band carbide enzima, kwindawo ephantsi yekhabhoni phakathi kwamaqela amabini ukwenza inaliti ye-martensite ebanzi, okubangela ubushushu bendalo. I-austenite eseleyo kwi-superheating organization iyanda, kwaye uzinzo olunemilinganiselo luyancipha. Ngenxa yobushushu be-quenching organization, i-crystal yentsimbi irhabaxa, eya kukhokelela ekunciphiseni ukuqina kwamalungu, ukumelana nempembelelo kuyancitshiswa, kwaye ubomi be-bearing buyancipha. Ubushushu obukhulu bunokubangela nokuqhekeka kokucima.

Ubushushu obungaphantsi

Ubushushu bokucima buphantsi okanye ukupholisa kakubi kuya kuvelisa okungaphezulu kunombutho oqhelekileyo weTorrhenite kwisakhiwo esincinci, esaziwa ngokuba ngumbutho ongaphantsi kobushushu, okwenza ubunzima buwe, ukumelana nokuguguleka kuncitshiswe kakhulu, okuchaphazela ubomi bebheying yeendawo zeroller.

Ukucima imifantu

Iindawo ezithwala iirola kwinkqubo yokucima nokupholisa ngenxa yoxinzelelo lwangaphakathi olwenzekileyo yimifantu ebizwa ngokuba yimifantu yokucima. Izizathu zezi mingxunya zezi: ngenxa yokucima ubushushu buphezulu kakhulu okanye ukuphola kukhawulezile kakhulu, uxinzelelo lobushushu kunye notshintsho lomthamo wesinyithi ekuhleleni uxinzelelo lukhulu kunamandla okuqhekeka kwentsimbi; umphezulu womsebenzi weziphene zokuqala (ezifana nemifantu yomphezulu okanye imikrwelo) okanye iziphene zangaphakathi kwintsimbi (ezifana ne-slag, izinto ezingafunekiyo zesinyithi, amabala amhlophe, intsalela yokuncitshiswa, njl.njl.) ekucimeni ukwakheka koxinzelelo; ukubola komphezulu okunzima kunye nokwahlulwa kweCarbide; iindawo ezicinyiweyo emva kokuqiniswa koxinzelelo ukungonelanga okanye ukufudunyezwa ngexesha; uxinzelelo olubandayo lwe-punch olubangelwa yinkqubo yangaphambili lukhulu kakhulu, ukugoba kwe-folding, ukusikwa okunzulu kokujika, imiqolo yeoyile imiphetho ebukhali njalo njalo. Ngamafutshane, unobangela wokucinywa kwemifantu unokuba yenye okanye ngaphezulu kwezi zinto zingasentla, ubukho boxinzelelo lwangaphakathi sesona sizathu siphambili sokwenziwa kwemifantu yokucima. Imifantu yokucima imifantu inzulu kwaye incinci, inemifantu ethe tye kwaye ayinambala we-oxidized kumphezulu ophukileyo. Idla ngokuba yi-longitudinal flat crack okanye i-ring-shaped crack kwi-bearing collar; imilo kwi-bearing steel ball inomfanekiso ka-S, i-T okanye i-ring-shape. Iimpawu zokulungelelanisa zokucima i-crack ayisiyonto yokudambisa ii-carburization kumacala omabini e-crack, eyahluke ngokucacileyo kwii-forging crack kunye nee-material crack.

Ukuguqulwa konyango lobushushu

Iindawo ezithwala i-NACHI kunyango lobushushu, kukho uxinzelelo lobushushu kunye noxinzelelo lombutho, olu xinzelelo lwangaphakathi lunokubekwa phezu komnye nomnye okanye luncitshiswe kancinci, luyinkimbinkimbi kwaye luyaguquguquka, kuba lunokutshintshwa ngobushushu bobushushu, izinga lokufudumeza, imo yokuphola, izinga lokuphola, imilo kunye nobukhulu beendawo, ngoko ke ukuguqulwa konyango lobushushu akunakuphepheka. Qaphela kwaye uyiqonde imithetho yomthetho kunokwenza ukuguqulwa kweendawo ezithwala izikhundla (ezifana ne-oval yekhola, ubungakanani obuphezulu, njl.njl.) zibekwe kuluhlu olulawulekayo, olulungele imveliso. Kakade ke, kwinkqubo yonyango lobushushu yokungqubana koomatshini kuya kwenza ukuguqulwa kweendawo, kodwa olu tshintsho lungasetyenziselwa ukuphucula ukusebenza ukuze kuncitshiswe kwaye kuphetshwe.

Ukususwa kwekhabhohayidreyithi kumphezulu

Izixhobo zerola ezithwala iindawo kwinkqubo yonyango lobushushu, ukuba zifudunyezwa kwindawo yokuxovula, umphezulu uya kuxovula ukuze inxalenye yekhabhoni yomphezulu weendawo incitshiswe, nto leyo ebangela ukuba i-surface decarburization ibe phezulu. Ubunzulu bomaleko wokuxovula umphezulu obungaphezulu kokulungiswa kokugqibela kobungakanani bokugcinwa kuya kwenza iindawo zilahlwe. Ukuqinisekiswa kobunzulu bomaleko wokuxovula umphezulu weendawo kwi-metallographic examination ye-metallographic method ekhoyo kunye ne-microhardness method. I-microhardness distribution curve yomaleko womphezulu isekelwe kwindlela yokulinganisa, kwaye ingasetyenziswa njengekhrayitheriya yokugweba.

Indawo ethambileyo

Ngenxa yokungafudumali ngokwaneleyo, ukupholisa okungekho semgangathweni, ukusebenza kokucima okubangelwa bubunzima bomphezulu obungafanelekanga kwiindawo ezithwala iirola akwanelanga into eyaziwa ngokuba yi-quenching soft spot. Kufana nokubola komphezulu kunokubangela ukwehla okukhulu kokumelana nokuguguleka komphezulu kunye namandla okudinwa.

Ixesha lokuthumela: Disemba-05-2023