1. Isishwankathelo seMveliso

Iladi yentsimbi eyenziwe ngokuhambelanaI-ASTM A27 Ibanga 70-36yintsimbi yekhabhoni esetyenziswa kakhulu eyenzelwe ukuphatha, ukuthutha, kunye nokugcina okwethutyana i-slag enyibilikisiweyo okanye izinto ezishushu kwizicelo zesinyithi kunye nezemizi-mveliso.

Eli banga likhethwe ngokukodwa ukubonelela ngebhalansi efanelekileyo phakathiamandla, ukuguquguquka, kunye nokumelana noxinzelelo lobushushu kunye nolwemishini, nto leyo eyenza ukuba ifaneleke ngakumbi kwiiladi ezisetyenziswa ngokuphindaphindiweyo ekuphakamiseni, ukujikeleza ngobushushu, kunye nokulayisha ngoxinzelelo.

2. Umgangatho oSebenzayo

I-ASTM A27 / A27M– Iintsimbi ezisetyenziswayo, iCarbon, ukuze isetyenziswe ngokubanzi

Ibanga lezinto:I-ASTM A27 Ibanga 70-36

Zonke izinto ezibunjiweyo kufuneka zenziwe, zivavanywe, kwaye zihlolwe ngokuhambelana ngokupheleleyo neemfuno ze-ASTM A27 ngaphandle kokuba kuchazwe ngenye indlela ngumthengi.

3. Iimpawu zezinto eziphathekayo – ASTM A27 Ibanga 70-36

I-ASTM A27 Grade 70-36 ludidi oluphakathi olusebenzisa isinyithi sekhabhoni olubonakala ngokuqina kakuhle kunye nokuthembeka kwesakhiwo.

3.1 Iipropati zoomatshini (Ubuncinane)

| Ipropati | Imfuneko |

| Tensile strength | ≥ 70,000 psi (≈ 485 MPa) |

| Unikeze Amandla | ≥ 36,000 psi (≈ 250 MPa) |

| Ukwandiswa (nge-2 in / 50 mm) | ≥ 22% |

| Ukunciphisa Indawo | ≥ 30% |

Ezi mpawu zoomatshini ziqinisekisa amandla aneleyo okuthwala umthwalo ngelixa zigcina ukumelana okuhle kakhulu nokuqhekeka nokuqhekeka okubuthathaka.

3.2 Ulwakhiwo lweeKhemikhali (Imida eqhelekileyo)

| I-elementi | Umxholo ophezulu |

| Ikhabhoni (C) | ≤ 0.35% |

| IManganese (Mn) | ≤ 0.70% |

| I-Phosphorus (P) | ≤ 0.05% |

| I-Sulfur (S) | ≤ 0.06% |

Umthamo wekhabhoni kunye ne-manganese olawulwayo unegalelo ekubumbeni okuzinzileyo kunye nokusebenza okuthembekileyo koomatshini ngaphandle kwesidingo sokudibanisa izinto.

4. Uyilo kunye neempawu zolwakhiwo lweLadle

l Umzimba otyhidiweyo oneqhekeza elinye okanye umzimba otyhidiweyo onezikhonkwane zokuphakamisa eziphoswe ngokupheleleyo / iilugs zokuphakamisa

l Ijiyometri yangaphakathi ethambileyo ukunciphisa uxinzelelo

l Ubukhulu bodonga obaneleyo obuyilelwe ukumelana nobushushu kunye nemithwalo yokuphatha ngoomatshini

l Iindawo zokuphakamisa eziyilwe ngokusekelwe kwiimeko zokuphakamisa umthwalo opheleleyo, kuquka nezinto zokhuseleko

Uyilo lwendebe lugxininisaukuthembeka kwesakhiwo kunye nokuqina kwenkonzo, ingakumbi xa kukho ubushushu obuphezulu kunye nokuphathwa kwekreyini ngokuphindaphindiweyo.

5. Inkqubo yoMveliso

5.1 Indlela Yokuphosa

l Ukuphoswa kwesanti kusetyenziswa izixhobo zokubumba ezilawulwayo ezifanelekileyo kwiiphostiki zentsimbi ezinkulu

l Ukuphoswa kobushushu obunye kuyacetyiswa ukuqinisekisa ukuhambelana kweekhemikhali

5.2 Ukunyibilikisa nokugalela

l Isithando somlilo se-arc sombane (EAF) okanye isithando somlilo sokungenisa

l Ulawulo olungqongqo lwemixube yeekhemikhali ngaphambi kokuthulula

l Ubushushu bokugalela obulawulwayo ukunciphisa iziphene zangaphakathi

5.3 Unyango lobushushu

Ukulungisa unyango lobushushuidla ngokusetyenziswa

Injongo:

l Hlaziya isakhiwo seenkozo

l Phucula ubulukhuni kunye neempawu ezifanayo zoomatshini

l Ukunciphisa uxinzelelo lwangaphakathi lokuphosa

Iiparameter zonyango lobushushu kufuneka zibhalwe phantsi kwaye zilandelelwe.

6. Ulawulo loMgangatho kunye noHlolo

6.1 Uhlalutyo lweeKhemikhali

l Uhlalutyo lobushushu olwenziwayo kwi-melt nganye

Iziphumo ezirekhodwe kwiSatifikethi soVavanyo lweMill (MTC)

6.2 Uvavanyo lweMishini

l Iikhuphoni zovavanyo eziphoswe kubushushu obufanayo kunye nokulungiswa kobushushu kunye neladle:

Uvavanyo lwe-Throjani

Ukuqinisekiswa kwamandla okuvelisa isivuno

l Ukwandiswa kunye nokunciphisa indawo

6.3 Uvavanyo Olungonakalisiyo (njengoko lufanelekile)

Ngokuxhomekeke kwiimfuno zeprojekthi:

Ukuhlolwa okubonakalayo (100%)

Uvavanyo lweMagnetic Particle (MT) lweentanda zomphezulu

Uvavanyo lwe-Ultrasonic (UT) lokuqinisekisa ukuba isandi sangaphakathi siphilile

6.4 Uvavanyo lweMilinganiselo

Ukuqinisekiswa ngokuchasene nemizobo evunyiweyo

l Ingqwalasela ekhethekileyo kwi-geometry yokuphakamisa iihoko kunye namacandelo abalulekileyo athwala umthwalo

7. Amaxwebhu kunye neSatifikethi

La maxwebhu alandelayo ahlala ebonelelwa:

Isatifikethi sovavanyo lweMill (EN 10204 3.1 okanye esilinganayo)

Ingxelo yokwakheka kweekhemikhali

Iziphumo zovavanyo loomatshini

l Irekhodi yonyango lobushushu

Iingxelo ze-NDT (ukuba ziyafuneka)

Ingxelo yokuhlolwa kobukhulu

Onke amaxwebhu alandelelwa kwi-heat and casting batch ehambelanayo.

8. Ububanzi beSicelo

Iilaphu zentsimbi ezenziwe kwi-ASTM A27 Grade 70-36 zisetyenziswa kakhulu kwezi:

l Izityalo zentsimbi kunye neefektri

Iinkqubo zokuphatha i-Slag

Iiworkshops zeMetallurgical

l Imisebenzi yokudlulisa izinto ezisetyenziswa kwimizi-mveliso enzima

Eli banga lifanelekile ngokukodwa kwizicelo aphoukuguquguquka kunye nokhuseleko phantsi komthwalo onamandlazibalulekile.

9. Iingenelo zokusebenzisa i-ASTM A27 Grade 70-36 kwiiLadles

l Ibhalansi egqwesileyo phakathi kwamandla kunye nokuguquguquka

l Umngcipheko oncitshisiweyo wokuqhekeka okubuthathaka phantsi koxinzelelo lobushushu

l Ixabiso elifanelekileyo xa lithelekiswa namanqanaba aphezulu anamandla, aphantsi okuguquguquka

l Ukuthembeka okuqinisekisiweyo kwezicelo zokuphosa ezinzima

l Yamkelwe ngokubanzi ngabahloli kunye neenkampani zobunjineli

Ulwazi lokuPakisha kunye nokuThutha

I-NCM ecetyisiweyo (iKhowudi yeRhafu):8454100000

Uhlobo lokuPakisha olusetyenzisiweyo:

Isikhidi okanye ikreyithi eyenziwe ngomthi eyenzelwe wena ukuze ithuthwe ngolwandle.

Ifilimu yokuthintela ukugqwala okanye i-oyile elwa nomhlwa esetyenziswa kwiindawo eziphezulu.

Zibambe ngentsimbi kwaye uzithintele ngomthi ukuze ungashukumi xa uhamba.

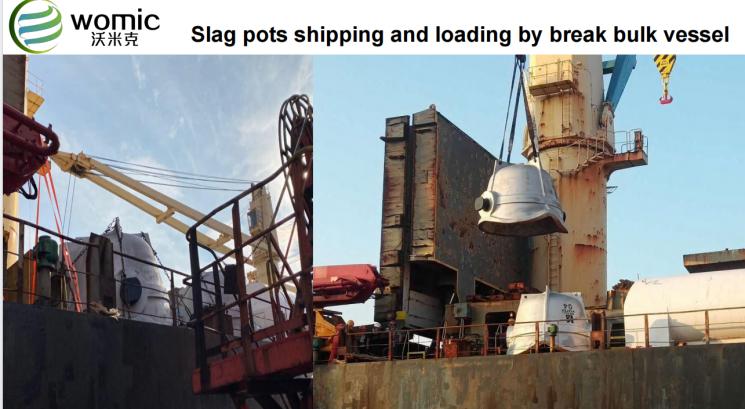

Uhlobo lweendlela zokuthumela:Isikhongozeli,inqanawa enkulu:

Isikhongozeli seRack eSicaba– Ikhethwayo ukuze kube lula ukulayisha/ukukhulula i-crane.

Vula isitya esingaphezulu– Isetyenziswa xa ukucanda ngokuthe nkqo kuyinto exhalabisayo.

Inqanawa Enkulu- Kuba ubukhulu obukhulu abukwazi ukulayishwa kwizikhongozeli

Ngaba ufuna ilayisenisi yoThutho lwasekuhlaleni?

Ewe, ngenxa yobukhulu beembiza,ilayisenisi yokuthutha ekhethekileyoidla ngokufuneka xa kuziswa ngendlela okanye ngololiwe. Amaxwebhu kunye nemizobo yobugcisa inganikezelwa ukunceda kwizicelo zeemvume.

Kwimeko yoMthwalo Okhethekileyo Omkhulu, Luhlobo Luni Lwezixhobo Eziza Kusetyenziselwa Ukuphathwa?

IiKreyini zeCrawlerenomthamo owaneleyo wobungakanani obuncinci nobunzima.

Iikhreni zaselunxwemenikwiimbiza ze-slag ezibunzima obungaphezulu kweetoni ezingama-28

Zonke iindawo zokuphakamisa zenziwe ngendlela eyiyo kwaye zavavanywa ukuqinisekisa ukuphathwa okukhuselekileyo nokuthobela imithetho.

10. Isiphelo

I-ASTM A27 Grade 70-36 lukhetho lwezinto ezisemgangathweni ngokwetekhnoloji nezisebenza kakuhle ngokwezoqoqosho kwiiladle zentsimbi ezisetyenziswa kwiindawo zoshishino ezifuna amandla. Iimpawu zayo zoomatshini, kunye nekhemistri elawulwayo kunye nonyango olufanelekileyo lobushushu, zibonelela ngokuthembeka kunye nokhuseleko lokusebenza ixesha elide.

Siyazingca ngeiinkonzo zokwenza ngokwezifiso, imijikelo yemveliso ekhawulezayokunyeinethiwekhi yokuhambisa umbane kwihlabathi liphela, ukuqinisekisa ukuba iimfuno zakho ezithile ziyafezekiswa ngokuchanekileyo nangokugqwesileyo.

Iwebhusayithi: www.womicsteel.com

I-imeyile: sales@womicsteel.com

Ucingo/WhatsApp/WeChat: Victor: +86-15575100681 okanye uJack: +86-18390957568

Ixesha leposi: Jan-22-2026