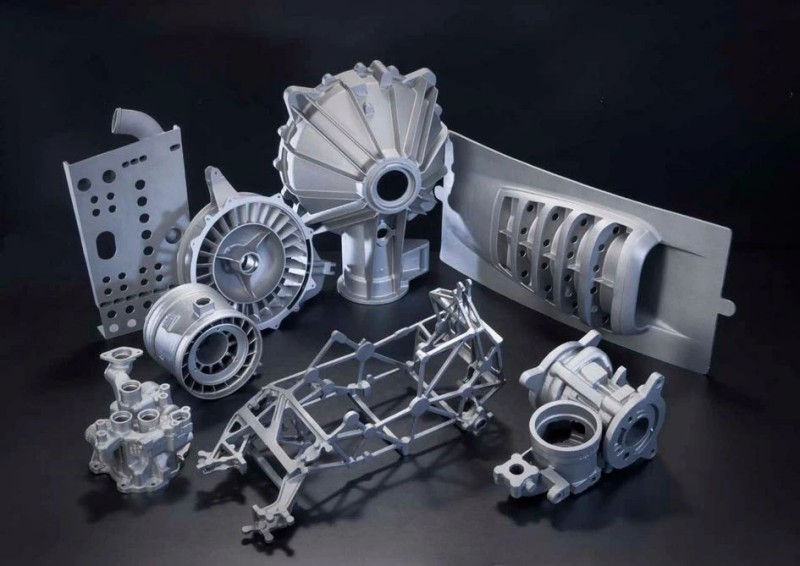

Isishwankathelo sezinto ze-Alloy

Inkcazo ye-Alloy

I-alloy ngumxube ofanayo owenziwe ziintsimbi ezimbini okanye ngaphezulu, okanye indibaniselwano yeentsimbi kunye nezinto ezingezizo zesinyithi, ezineempawu zesinyithi. Ingcamango yoyilo lwe-alloy kukudibanisa izinto ngendlela yokuphucula iimpawu zoomatshini, zomzimba, kunye neekhemikhali ukuhlangabezana neemfuno ezithile zezicelo ezahlukeneyo.

Ulwahlulo lwezixhobo ze-Alloy

Izinto ze-alloy zingahlulwa ngokwezinto eziphambili kunye neempawu zazo ngolu hlobo lulandelayo:

●Ii-Alloys zeFerrous:Ezi zii-alloys ezisekwe kwisinyithi ezinee-elements ezongezelelweyo ezifana ne-carbon, i-manganese, kunye ne-silicon, ezisetyenziswa kakhulu kwimizi-mveliso yokwenza intsimbi kunye nokuthunga.

●Ii-Aluminium Alloys:Ezi zii-alloys ezisekelwe kwi-aluminium ezinezinto ezifana ne-copper, i-magnesium, kunye ne-zinc, ezaziwa ngokuba zikhaphukhaphu, ziqinile, kwaye zineempawu ezibalaseleyo zokuqhuba umbane kunye nobushushu.

●Ii-Alloys zobhedu:Ezi zii-alloys ezisekelwe kubhedu ezinee-elements ezongezelelweyo ezifana ne-zinc, i-tin, kunye ne-lead, ezibonelela ngokuhambisa kakuhle, ukumelana nokugqwala, kunye nokusebenza kakuhle.

●Ii-Magnesium Alloys:Ii-alloys ezisekelwe kwi-magnesium, ezidla ngokudityaniswa ne-aluminium, i-zinc, kunye ne-manganese, zezona zinyithi zikhaphukhaphu zesakhiwo ezinokumelana kakuhle nokutshatyalaliswa kobushushu.

●Ii-Nickel Alloys:Iialloy ezisekelwe kwi-nickel ziqulathe izinto ezifana ne-chromium, isinyithi, kunye ne-cobalt, kwaye zinokumelana nokugqwala okugqwesileyo kunye nokusebenza kakuhle kumaqondo obushushu aphezulu.

● IiAlloys zeTitanium:Eyaziwa ngamandla ayo aphezulu, uxinano oluphantsi, kunye nokumelana nokugqwala okugqwesileyo, ii-alloys ezisekelwe kwi-titanium zisetyenziswa kakhulu kwizicelo zeenqwelo-moya.

Ii-Alloys zeFerrous

Ukwakhiwa kunye neempawu zeFerrous Alloys

Ii-alloys ze-ferrous zenziwe ngentsimbi enezinto ezahlukeneyo zokudibanisa eziphucula iimpawu zazo zobugcisa. Izinto eziqhelekileyo ziquka:

●Ikhabhoni:Enye yezona zinto zibalulekileyo zokudibanisa, umxholo wekhabhoni ohlukeneyo kwii-alloys ze-ferrous uchaphazela ubulukhuni kunye nokuqina. Ii-alloys ezinekhabhoni ephezulu zinika ubulukhuni obungakumbi kodwa ubulukhuni obuncinci.

●Isilicon:I-silicon iphucula amandla kunye nokuqina kwee-alloys ze-ferrous kwaye isetyenziswa rhoqo kwii-alloys ze-silicon-iron ekwenzeni intsimbi njenge-deoxidizer kunye ne-alloying agent.

●IManganese:I-Manganese ibalulekile ekonyuseni amandla kunye nokuqina kwee-alloys ze-ferrous, kwaye ii-alloys ze-ferromanganese zibalulekile ekuphuculeni ukumelana nokuguguleka kwentsimbi kunye nokumelana nokugqwala.

●I-Chromium:Ii-alloy ze-chromium-iron zibonelela ngokumelana nokugqwala okugqwesileyo kunye namandla obushushu obuphezulu, ezisetyenziswa kakhulu ekuveliseni intsimbi engagqwaliyo kunye neentsimbi ezikhethekileyo.

Ukusetyenziswa kweeFerrous Alloys

Ii-alloys ze-ferrous zisetyenziswa kakhulu kumashishini ahlukeneyo, kuquka:

●Ishishini Lokwenza Intsimbi:Ii-alloys ze-ferrous zezona zongezo zibalulekileyo kwimveliso yentsimbi, ezisetyenziselwa ukutshintsha ukwakheka kwentsimbi kunye nokuphucula iimpawu zayo.

●Ishishini lokuphosa:Kwiinkqubo zokuphosa, ii-alloys ze-ferrous ziphucula iipropati zoomatshini kunye nokuqina kweemveliso zesinyithi esityhidiweyo.

●Izinto zokuWelda:Ii-alloys ze-ferrous zisetyenziswa ekuveliseni iintonga ze-welding kunye ne-flux ukuqinisekisa ukuba ii-weld joints zisemgangathweni ophezulu.

●Imizi-mveliso yeekhemikhali nezichumisi:Ii-alloys ze-ferrous zisebenza njengee-catalysts kunye nee-reducing agents kwimveliso yeekhemikhali kunye nezichumiso.

●Ukusebenza ngentsimbi:Ii-alloys ze-ferrous zisetyenziswa kwizixhobo ezifana nezixhobo zokusika kunye nee-molds, nto leyo ephucula ukuqina kwazo kunye nokusebenza kwazo kakuhle.

IiAluminiyam zeAluminiyam

Iimpawu eziphambili ze-aluminium alloys

Ii-alloys ze-aluminium ziyaziwa ngokukhanya kwazo, amandla aphezulu, kunye nokulula kokucutshungulwa, nto leyo eyenza ukuba zibe yimfuneko kumashishini anamhlanje. Iimpawu eziphambili ziquka:

●Ilula:Ii-alloys ze-aluminium zinobunzima obuphantsi obumalunga ne-2.7 g/cm³, nto leyo eyenza ukuba zilungele ukusetyenziswa ezifuna ukunciphisa ubunzima.

● Amandla Aphezulu:Ngokusebenzisa i-alloy kunye nonyango lobushushu, ii-alloy ze-aluminium zinokufikelela kumandla aphezulu okutsalwa, ezinye ii-alloy zingaphaya kwe-500 MPa.

●Ukuqhuba kakuhle kakhulu:I-aluminium ecocekileyo yi-conductor ebalaseleyo yombane kunye nobushushu, kwaye ii-alloys ze-aluminium zigcina inxalenye enkulu yezi mpawu.

●Ukumelana nokugqwala:Umaleko we-oxide wendalo uvela phezu komphezulu wee-alloys ze-aluminium, nto leyo enika ukumelana nokugqwala okugqwesileyo, kwaye unyango olukhethekileyo lunokuphucula ngakumbi le propati.

●Ukulula Kokucubungula:Ii-alloys ze-aluminium zinobuplastiki obuhle, nto leyo ezenza zilungele iinkqubo zokubumba, zokukhupha, nezokwakha.

Amanqanaba kunye nosetyenziso lwee-aluminium alloys

Ii-alloys ze-aluminium zahlulwe ngokusekelwe kwizinto eziphambili kunye neempawu zazo zokudibanisa. Ezinye iiklasi eziqhelekileyo ziquka:

●Uthotho lwe-1xxx:I-aluminium ecocekileyo, enomxholo we-aluminium ongaphezulu kwe-99.00%, isetyenziswa kakhulu kwishishini lombane nakwiimpahla zabathengi zemihla ngemihla.

●Uthotho lwe-2xxx:Ubhedu yeyona nto iphambili yokudibanisa, iphucula kakhulu amandla emva konyango lobushushu, esetyenziswa kakhulu kwizicelo zeenqwelo-moya.

●Uthotho lwe-3xxx:I-Manganese yeyona nto iphambili ekudibaniseni izinto, inika ukumelana okuhle nokugqwala, isetyenziswa kakhulu ekwakheni nakwizinto zokwakha.

●Uthotho lwe-4xxx:I-silicon yeyona nto iphambili yokudibanisa, enika ukumelana nobushushu kunye neempawu ezilungileyo zokuwelda, ifanelekile kwizixhobo zokuwelda kunye nezixhobo ezimelana nobushushu.

●Uthotho lwe-5xxx:I-Magnesium yeyona nto iphambili yokudibanisa, inika iipropati ezintle kakhulu zoomatshini kunye nokumelana nokugqwala, esetyenziswa kumashishini aselwandle, eemoto, kunye neenqwelo-moya.

●Uthotho lwe-6xxx:I-Magnesium kunye ne-silicon zezona zinto ziphambili zokudibanisa, zibonelela ngamandla alungileyo kunye nokusebenza kakuhle, ezisetyenziswa kakhulu kwizixhobo zokwakha.

●Uthotho lwe-7xxx:I-Zinc yeyona nto iphambili yokudibanisa, kwaye ezi ngxube zinika amandla aphezulu, asetyenziswa kakhulu kwizakhiwo zeenqwelo-moya kunye nokusetyenziswa kwamandla aphezulu.

●Uthotho lwe-8xxx:Ziqulathe ezinye izinto ezifana nentsimbi kunye ne-nickel, ezinika amandla alungileyo kunye nokuqhuba kakuhle, ezisetyenziswa kakhulu kwishishini lombane.

Ii-alloys ze-aluminium zisetyenziswa kumacandelo ahlukeneyo, kuquka:

●Indawo yomoya:Ii-alloy ze-aluminium ezikhaphukhaphu nezinamandla aphezulu zibalulekile kwizakhiwo zeenqwelo-moya kunye nezinto ezisetyenziswa kuzo.

●Uthutho:Ii-alloys ze-aluminium zisetyenziselwa ukuvelisa izixhobo zemoto ezilula kunye nezoololiwe, nto leyo ephucula ukusetyenziswa kakuhle kwepetroli.

●Ishishini loMbane:I-aluminium yinto ekhethwayo kwiintambo kunye neetransformer

●Ulwakhiwo:Ii-alloys ze-aluminium zisetyenziswa kakhulu kwizakhiwo zokwakha, kwizakhelo zeefestile, kwiingcango, nakwiiphahla ngenxa yamandla azo, ukumelana nokugqwala, kunye nenkangeleko entle.

●Ukupakisha:Ii-alloys ze-aluminium, ingakumbi ezikwimo yeefoyile kunye neetini, zisetyenziswa kakhulu kushishino lokupakisha kuba zilula, azinatyhefu, kwaye zinokuphinda zisetyenziswe kakhulu.

IiAlloys zeCopper

Ukwakhiwa kunye neempawu zeCopper Alloys

Ii-alloy ze-copper zaziwa ngokusebenza kwazo kakuhle kombane kunye nobushushu, ukumelana nokugqwala, kunye nokulula kokwenziwa. Ii-alloy ze-copper eziqhelekileyo ziquka:

●Ithusi (I-Copper-Zinc Alloy):Iyaziwa ngamandla ayo, ukuguquguquka kwayo, kunye nokumelana nokugqwala, ibrass isetyenziswa kakhulu kwizicelo zoomatshini, imibhobho, kunye nezixhobo zomculo.

●I-Bronze (I-Copper-Tin Alloy):Le alloy inika ukumelana nokugqwala okuphezulu, ubulukhuni, kunye nokumelana nokuguguleka, okuhlala kusetyenziswa kwiibheringi, ii-bushings, kunye nokusetyenziswa kolwandle.

●Ii-Alloys zeCopper-Nickel:Ezi alloys zibonelela ngokumelana nokugqwala okugqwesileyo kwiindawo zaselwandle, nto leyo ezenza zibe zilungele ukwakha iinqanawa, amaqonga aselunxwemeni, kunye nezityalo zokukhupha ityuwa emanzini.

●Ubhedu lweBeryllium:Ngenxa yokuba inamandla aphezulu, ubulukhuni, kunye nokumelana nokugqwala, i-beryllium copper idla ngokusetyenziswa kwizixhobo ezichanekileyo, izihlanganisi zombane, kunye nezipringi.

Ukusetyenziswa kweCopper Alloys

Ii-alloy ze-copper zisebenza kuluhlu olubanzi lwamashishini ngenxa yokuguquguquka kwazo kunye neempawu zazo ezizodwa:

●Ishishini loMbane:Ii-alloy ze-copper zisetyenziswa kakhulu kwizihlanganisi zombane, kwiintambo, nakwiinxalenye ngenxa yokuba ziqhuba kakuhle kakhulu.

●Ukuphatha iiPlumbing kunye noLwakhiwo:I-brass kunye ne-bronze zisetyenziswa kakhulu kwiivalvu, izixhobo, kunye nezinye izinto zokufaka imibhobho ngenxa yokumelana kwazo nokugqwala.

●Ishishini leenqanawa:Ii-alloy ze-copper-nickel zithandwa kakhulu kwiindlela zaselwandle ngenxa yokuba zichasa kakhulu ukugqwala kwamanzi olwandle.

●Ubunjineli Bokuchaneka:I-Beryllium copper isetyenziswa kwizixhobo, kwizixhobo ezingatshisi mlilo, nakwizinto ezichanekileyo ngenxa yokuba inamandla kwaye ihlala ixesha elide.

Ii-Alloys zeMagnesium

Iimpawu zeMagnesium Alloys

Ii-alloy zeMagnesium zezona zinyithi zikhaphukhaphu zesakhiwo, ezinomlinganiselo ogqwesileyo wamandla nobunzima, ukufunxwa komothuko, kunye nokusebenza kakuhle komatshini. Iimpawu eziphambili ziquka:

●Ilula:Ii-alloy zeMagnesium zikhaphukhaphu ngama-35% kune-aluminium kwaye zikhaphukhaphu ngama-78% kunentsimbi, nto leyo eyenza ukuba zilungele ukusetyenziswa ngokulula.

●Ukusebenza kakuhle:Ii-alloys zeMagnesium zinobuchule obuhle bokusebenza, nto leyo evumela ukuba iindawo ezintsonkothileyo nezichanekileyo zenziwe ngokufanelekileyo.

●Ukufunxwa Komothuko:Ezi alloys zineempawu ezilungileyo zokufunxa ukutshayiswa, nto leyo ezenza zibe luncedo kwiimoto nakwiindawo zomoya.

●Ukusasazwa kobushushu:Ii-alloy ze-magnesium zibonelela ngokutshabalalisa ubushushu ngempumelelo, nto leyo ebalulekileyo kwii-elektroniki nakwizinto ezisebenzisa ubushushu obuphezulu.

Ukusetyenziswa kweMagnesium Alloys

Ngenxa yokukhanya kwazo kunye namandla azo, ii-magnesium alloys zisetyenziswa kumashishini ahlukeneyo:

●Ishishini leeMoto:Ii-alloy ze-magnesium zisetyenziswa kwiindawo zeenjini, kwiindawo zokuhambisa umbane, nakwiivili ukunciphisa ubunzima besithuthi nokuphucula ukusebenza kakuhle kwepetroli.

●Ishishini leeNqwelo-moya:Ii-alloys zeMagnesium zisetyenziswa kwiindawo zeenqwelo-moya nakwiindawo zeenqwelo-moya apho ukunciphisa ubunzima kubalulekile khona.

●Izixhobo ze-elektroniki:Ii-alloy zeMagnesium zisetyenziswa ekwenzeni iilaptops ezilula, iikhamera, kunye neefowuni eziphathwayo ngenxa yamandla azo kunye neempawu zokusasaza ubushushu.

● Izixhobo zonyango:Ii-alloy zeMagnesium zisetyenziswa kwizixhobo ezifakwa kwi-bioresorbable kunye nezixhobo zamathambo ngenxa yokuhambelana kwazo kwi-biocompatibility.

Ii-Nickel Alloys

Iipropati zeNickel Alloys

Ii-alloy ze-nickel zaziwa ngokumelana kwazo nokugqwala okugqwesileyo, ukuzinza kumaqondo obushushu aphezulu, kunye namandla oomatshini. Zihlala zixutywe ne-chromium, isinyithi, kunye nezinye izinto ukuphucula ukusebenza kwiindawo ezixineneyo. Iimpawu eziphambili ziquka:

●Ukumelana nokugqwala:Ii-alloy ze-nickel zinokumelana okuhle kakhulu ne-oxidation kunye nokugqwala kwiindawo ezinobungozi, kuquka amanzi olwandle kunye neemeko ze-asidi.

●Ubushushu obuphezulu:Ii-alloy ze-nickel zigcina amandla azo kumaqondo obushushu aphezulu, nto leyo eyenza ukuba zilungele ukusetyenziswa kwizicelo zeenqwelo-moya kunye nokuveliswa kombane.

●Ukumelana nokunxitywa:Ii-alloy ze-nickel zibonelela ngokumelana nokuguguleka okuhle, nto leyo ebaluleke kakhulu xa kusenziwa izinto ezifuna ukuqina ixesha elide.

Ukusetyenziswa kweeNickel Alloys

Ii-alloys ze-nickel zisetyenziswa kwizicelo ezifunwayo kwiindawo ezahlukeneyo:

●Ishishini leeNqwelo-moya:Ii-superalloys ezisekelwe kwi-nickel zisetyenziswa kwiinjini zejethi, ii-turbine blades, kunye nezinye izinto ezishushu kakhulu ngenxa yokumelana kwazo nobushushu.

●Ukucubungula iikhemikhali:Ii-alloy ze-nickel zisetyenziswa kwii-reactors, kwi-heat exchangers, nakwiinkqubo zemibhobho apho ukumelana nokugqwala kunye namaqondo obushushu aphezulu kubalulekile.

●Ukuveliswa koMbane:Ii-alloy ze-nickel zisetyenziswa kwi-reactors zenyukliya nakwii-turbines zegesi ngenxa yezakhono zazo zobushushu obuphezulu kunye nokumelana nokugqwala.

●Ishishini leenqanawa:Ii-alloy ze-nickel zisetyenziswa kwiindawo zaselwandle kwizicelo ezifana neempompo, iivalvu, kunye nezixhobo zokususa ityuwa emanzini olwandle.

Ii-Alloys zeTitanium

Iimpawu zeTitanium Alloys

Iialloy zeTitanium zikhaphukhaphu kodwa zinamandla, zinokumelana nokugqwala okugqwesileyo kunye nozinzo kumaqondo obushushu aphezulu. Iimpawu eziphambili ziquka:

●Umlinganiselo Ophezulu Wokuqina Komzimba:Iialloy zetitanium ziqinile njengentsimbi kodwa zikhaphukhaphu phantse ngama-45%, nto leyo eyenza ukuba zilungele ukusetyenziswa kwi-aerospace nakwi-high function.

●Ukumelana nokugqwala:Iialloy zetitanium zinika ukumelana okugqwesileyo nokugqwala, ingakumbi emanzini olwandle nakwiindawo ezineekhemikhali.

●Ukuhambelana kwezinto eziphilayo:Ii-alloys ze-titanium ziyahambelana ne-biocompatible, nto leyo eyenza ukuba zilungele ukusetyenziswa kwezonyango kunye nezixhobo.

●Uzinzo lobushushu obuphezulu:Iialloy zetitanium zinokumelana nobushushu obugqithisileyo, zigcina amandla azo kunye nokuthembeka kwazo kwiindlela zeenqwelo-moya nakwimizi-mveliso.

Ukusetyenziswa kweTitanium Alloys

Ii-alloys zeTitanium zisetyenziswa kakhulu kumashishini apho amandla aphezulu, ukhaphukhaphu, kunye nokumelana nokugqwala kubalulekile:

●Ishishini leeNqwelo-moya:Iialloy zetitanium zisetyenziswa kwiifreyimu zeenqwelo-moya, izinto zenjini, kunye nezixhobo zokufika ngenxa yokuba zinamandla aphezulu kwaye zigcina ubunzima.

● Izixhobo zonyango:Ii-alloys ze-titanium zisetyenziswa kwi-orthopedic implants, kwi-dental implants, nakwizixhobo zotyando ngenxa yokuba ziyahambelana kwaye zihlala ixesha elide.

●Ishishini leenqanawa:Iialloy zetitanium zisetyenziswa kwiindawo ezingaphantsi kolwandle, ekwakheni iinqanawa, nasekugrumbeni olwandle ngenxa yokumelana nokugqwala kwazo.

●Izicelo zemizi-mveliso:Ii-alloys ze-titanium zisetyenziswa kwizityalo zokucubungula iikhemikhali, ukuvelisa umbane, kunye nokusetyenziswa kweemoto kwiindawo ezifuna amandla kunye nokumelana nokugqwala.

Isiphelo

Izinto ze-alloy zidlala indima ebalulekileyo kumashishini anamhlanje, zibonelela ngezisombululo ezenzelwe wena ezineendibaniselwano ezikhethekileyo zamandla, ubunzima, ukumelana nokugqwala, kunye nokuqina. Ukusuka kwi-aerospace ukuya kwiimoto, ulwakhiwo ukuya kwizixhobo zonyango, ukuguquguquka kwezinto ze-alloy kuzenza zibe yinto ebaluleke kakhulu kwizicelo ezininzi. Nokuba ngamandla aphezulu e-alloy ze-ferrous, iimpawu ezilula ze-alloy ze-aluminium, okanye ukumelana nokugqwala kwe-nickel kunye ne-titanium alloys, ii-alloy zenzelwe ukuhlangabezana neemfuno ezahlukeneyo zehlabathi lanamhlanje eliphucukileyo kwezobuchwepheshe.

Ixesha leposi: Oktobha-17-2024