Ubunjineli Bokuchaneka Kwezicelo Zokusebenza Okuphezulu

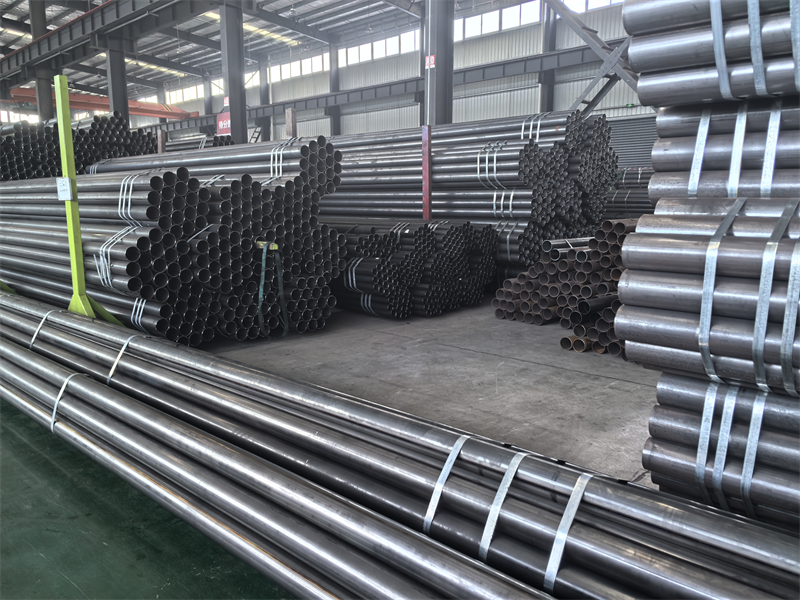

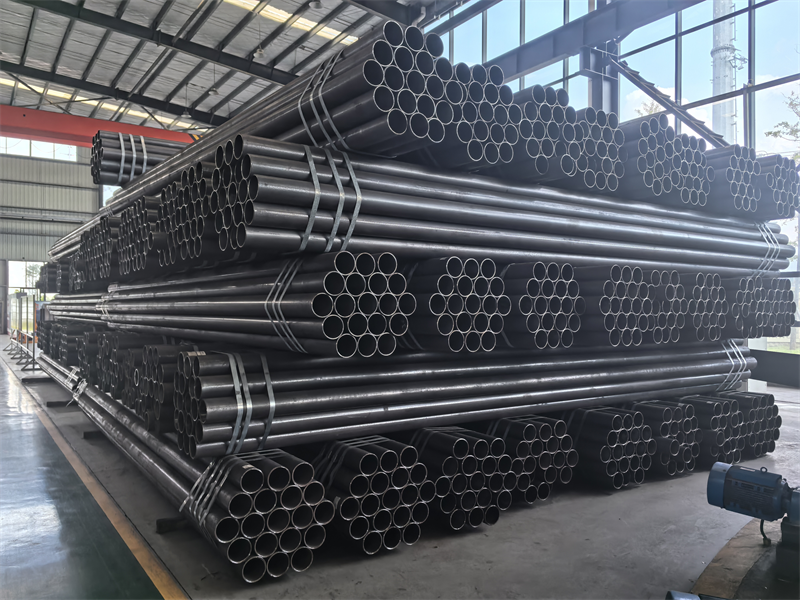

I-Womic Steel ngumvelisi owaziwayo kwihlabathi liphela weetyhubhu zerola zokuhambisa ezikumgangatho ophezulu. Ezi tyhubhu zizinto ezibalulekileyo kwiinkqubo zerola zokuhambisa, ezisetyenziswa kakhulu kwi-logistics, kwimigodi, kwi-metallurgy, kwizibuko, ekulungisweni kokutya, nakwamanye amashishini. Ezaziwa ngokuqina kwazo, ukuchaneka, kunye nokuzivumelanisa nezimo, iityhubhu zerola zokuhambisa ze-Womic Steel zenzelwe ukuhlangabezana neemeko zokusebenza ezahlukeneyo.

Amabanga ezinto kunye neenkcukacha

I-Womic Steel iqinisekisa ukusetyenziswa kwezixhobo ezikumgangatho ophezulu ukuze ziqine kakhulu, zikwazi ukumelana nokuguguleka, kwaye zikhusele ukugqwala.

Amabanga ezinto eziqhelekileyo

- Intsimbi yeCarbonQ195, Q235, Q345, S235JR, S355JR

- Yenziwe ngentsimbi eshayinayo: 201, 304, 316L (ilungele iindawo ezingcolisayo)

- Intsimbi ye-alloy: 16Mn, 20Mn2, 30MnSi (ifanelekile kwizicelo ezinamandla aphezulu)

- Intsimbi Egalelweyo: Ukumelana nokugqwala okuphuculweyo

Imigangatho Esebenzayo

Iimveliso zethu zihambelana nemigangatho eyahlukeneyo yamazwe ngamazwe neyengingqi:

- I-ASTM: ASTM A513, ASTM A106, ASTM A312

- EN: EN 10210, EN 10219, EN 10305

- I-JIS: I-JIS G3445, I-JIS G3466

- I-ISO: ISO 10799

- I-SANS: SANS 657-3 (Imigangatho yaseMzantsi Afrika yetyhubhu yokuhambisa impahla)

Inkqubo yeMveliso

I-Womic Steel isebenzisa iindlela zokuvelisa eziphambili kunye nezixhobo zanamhlanje ukuze inike iityhubhu zerola zokuhambisa ezichanekileyo nezithembekileyo.

1. Ukukhethwa kwezinto eziluhlaza

Iikhoyili zentsimbi ezikumgangatho ophezulu zikhethwa ngononophelo kwaye zivavanyelwe iimpawu zoomatshini kunye neekhemikhali.

2. Ukwenziwa kweThubhu

- Ukuqengqeleka Okubandayo: Ivelisa iityhubhu ezibhityileyo ezinobukhulu obufanayo kunye nomphezulu ogudileyo.

- Ukuqengqeleka Okushushu: Ilungele iityhubhu ezibiyelweyo ezinodonga oluqinileyo ezinamandla aphezulu kunye nokumelana nokuchasana.

- Iityhubhu eziWelding eziQhelekileyo kakhulu: Ibonelela ngee-welds eziqinileyo nezingenamthungo.

3. Ubuchule obuchanekileyo

Izixhobo ze-CNC ezizenzekelayo ziqinisekisa ukuba iityhubhu zenziwe ngobude obuchanekileyo, ububanzi, kunye nobukhulu bodonga.

4. Unyango lobushushu

Unyango lobushushu olulungiselelwe wena (ukunciphisa, ukulungisa, ukucima, ukufudumala) luphucula ukuqina kunye nokumelana nokuguguleka.

5. Unyango Lomphezulu

- Ukukha kunye nokuPasa: Isusa ukungcola kwaye yonyusa ukumelana nokugqwala.

- Ukugaya nge-galvanizing: Yongeza umaleko we-zinc ukukhusela umhlwa ixesha elide.

- Ukupeyinta okanye ukugquma: Ukhetho lokufaka ikhowudi yombala kunye nokhuseleko olongezelelweyo.

6. Uhlolo loMgangatho

Zonke iityhubhu zilawulwa ngononophelo lomgangatho, kuquka:

- Uvavanyo lokuchaneka kobukhulu: Ububanzi kunye ne-Ovality yangaphandleUkunyamezela ngaphakathi kwe-±0.1 mm.

- Uvavanyo lweMishini: Amandla okutsalwa, amandla okukhupha, kunye novavanyo lobude.

- Uvavanyo Olungonakalisiyo (NDT): Uvavanyo lwe-ultrasonic kunye ne-eddy current.

- Uhlolo lomphezulu: Iqinisekisa ukugqitywa okungenaziphene.

Uluhlu lobungakanani kunye nokunyamezela

I-Womic Steel inikezela ngeendidi ezahlukeneyo zeetyhubhu zerola zokuhambisa, ezinokwenziwa ngokwezifiso ukuze zihambelane neemfuno zakho.

| Ipharamitha | Uluhlu |

| Ububanzi obungaphandle (OD) | 20 mm - 300 mm |

| Ubukhulu bodonga (WT) | 1.5 mm - 15 mm |

| Ubude | Ukuya kuthi ga kwiimitha ezili-12 (ubungakanani obulungiselelwe wena buyatholakala) |

| Ukunyamezelana | Iyahambelana nemigangatho ye-EN 10219 kunye ne-ISO 2768 |

Ezona mpawu

1.Ukuqina Okumangalisayo

Yenzelwe ukumelana nemithwalo enzima kunye neemeko zokusebenza ezinzima.

2.Ukumelana nokugqwala

Ifumaneka ngentsimbi egqunyiweyo okanye engatyiwayo kwiindawo ezifumileyo nezinoburhalarhume beekhemikhali.

3.Ukuchaneka kunye nozinzo

Ukuthe tye okugqwesileyo kunye nokuxinana kunciphisa ukungcangcazela kunye nengxolo kwiinkqubo zokuhambisa.

4.Ukugcinwa Okuphantsi

Ukusebenza ixesha elide kunciphisa iindleko zokungasebenzi kunye nokugcinwa.

Izicelo

Iityhubhu zerola zokuhambisa zeWomic Steel zisetyenziswa kakhulu kwezi:

- Uthutho kunye neNdawo yokugcina impahla: Iinkqubo zokuhlela, ii-roller conveyors.

- Imigodi kunye neMetallurgy: Iinkqubo zokuphatha izinto ezininzi.

- Ukulungiswa kokutya: Iityhubhu zentsimbi engagqwaliyo ezicocekileyo zeendawo ezicocekileyo.

- IiPorts kunye neeTerminals: Iinkqubo zokuhambisa impahla.

- Amachiza kunye namayeza: Iirola ezimelana nokugqwala zokuphatha iikhemikhali.

Izisombululo ezenziwe ngokwezifiso

Sinikezela ngeendlela ezinokwenziwa ngokwezifiso ngokupheleleyo ukuze zihambelane neemfuno zeprojekthi ezizodwa:

- Ubungakanani obungengobuqhelekileyo: Ubukhulu obulungiselelwe izixhobo ezithile.

- Unyango lomphezulu: Ukupeyinta, ukupeyinta, okanye ukushukumisa umzimba.

- Iindlela zokuPakisha: Ukupakisha okwenziwe ngokwezifiso ukuqinisekisa ukuthuthwa okukhuselekileyo.

Isiphelo

Iityhubhu zerola zokuhambisa zeWomic Steel zenzelwe ukuhlangabezana nemigangatho ephezulu yoshishino kwaye zinikeze ukusebenza okugqwesileyo. Ngenxa yezakhono zokuvelisa eziphambili, ulawulo oluqinileyo lomgangatho, kunye neendlela zokwenza ngokwezifiso, iimveliso zethu zilukhetho oluthembekileyo kumashishini ahlukeneyo kwihlabathi liphela.

Ukuze ufumane ulwazi oluthe kratya okanye isicatshulwa esenziwe ngokwezifiso, nxibelelana neWomic Steel namhlanje!

I-imeyile: sales@womicsteel.com

MP/WhatsApp/WeChat:UVictor:+86-15575100681 UJack: +86-18390957568

Ixesha leposi: Jan-08-2025