Isishwankathelo seMveliso

I-Womic Steel ngumvelisi ophambili weI-EN 10305Iityhubhu zentsimbi ezingenamthungo eziqinisekisiweyo, ezenzelwe ukuchaneka, amandla, kunye nokuqina kuzo zonke izicelo zoshishino. Iityhubhu zethu zentsimbi ezingenamthungo zenzelwe ukuhlangabezana nemigangatho engqongqo yamazwe ngamazwe, zibonelela ngokusebenza kakuhle kwiinkqubo zothutho lwe-mechanical, structure, kunye nolwelo. Ukusuka kubunjineli beemoto ukuya kwiisilinda ze-hydraulic, i-Womic Steel iqinisekisa ukuba ityhubhu nganye yenzelwe ukugqwesa, iqinisekisa umgangatho ogqwesileyo kunye nokuthembeka.

ZethuIityhubhu zentsimbi ezingenamthungo ze-EN 10305zilungele ukusetyenziswa ngamandla aphezulu afuna ubungakanani obuchanekileyo, iimpawu ezibalaseleyo zoomatshini, kunye nokumelana okuqinileyo nokuguguleka kunye nokubola. Ezi tyhubhu zisetyenziswa kumacandelo amaninzi amashishini, kuquka iimoto, oomatshini, ukuthuthwa kolwelo, kunye nobunjineli boomatshini, zibonelela ngezisombululo ezithembekileyo zokusetyenziswa kobunjineli obuchanekileyo.

Uluhlu lweMveliso yeetyhubhu zentsimbi engenamthungo ze-EN 10305

Abavelisi beWomic SteelIityhubhu zentsimbi ezingenamthungo ze-EN 10305kwiindidi ezahlukeneyo zobukhulu kunye nobukhulu, okuqinisekisa ukuguquguquka kwezicelo ezahlukeneyo. Uluhlu oluqhelekileyo lwemveliso luquka:

- Ububanzi obungaphandle (OD): 6 mm ukuya kwi-406mm

- Ubukhulu bodonga (WT): 1 mm ukuya kwi-18 mm

- Ubude: Ubude obulungiselelwe wena, obuhlala buqala kwiimitha ezi-6 ukuya kwezili-12, bufumaneka xa umthengi ecela.

Ezi tyhubhu zinokwenziwa ngeemfuno ezithile zeedayamitha ezenziwe ngokwezifiso, ubude, kunye nobukhulu bodonga ngokusekelwe kwiinkcukacha zabathengi kunye neemfuno zeprojekthi.

Iityhubhu zentsimbi ezingenamthungo ze-EN 10305

I-Womic Steel'sIityhubhu zentsimbi ezingenamthungo ze-EN 10305zenziwe zigxile ekuchanekeni. Siqinisekisa ukunyamezelana okunemilinganiselo elandelayo kwiimveliso zethu

| Ipharamitha | Ukunyamezelana |

| Ububanzi obungaphandle (OD) | ± 0.01 mm |

| Ubukhulu bodonga (WT) | ± 0.1 mm |

| Ukuqanda (Ukuqanda) | 0.1 mm |

| Ubude | ± 5 mm |

| Ukuthe tye | Ubuninzi yi-0.5 mm ngemitha nganye |

| Umphezulu wokugqiba | Ngokweemfuno zomthengi (ngokwesiqhelo: Ioyile echasene nomhlwa, i-Hard Chrome Plating, i-Nickel Chromium Plating, okanye ezinye izinto zokugquma) |

| Isikwere seziphelo | ± 1° |

Iimeko zokuhanjiswa kweetyhubhu zentsimbi engenamthungo ze-EN 10305

Iityhubhu zenziwe kusetyenziswaumzobo obandayookanyeukuqengqeleka okubandayoiinkqubo kwaye zibonelelwa kwiimeko ezahlukeneyo zokuhanjiswa ngokusekelwe kwiimfuno ezithile zabathengi. Ezi ziquka:

Itheyibhile 1 — Iimeko zokuhanjiswa

| Ukutyunjwa | Isimbolia | Inkcazo |

| Itsalwe kubanda / iqinile | +C | Akukho unyango lokugqibela lobushushu emva kokuba kutsalwe ubushushu bokugqibela. |

| Itsalwe ngokubandayo / ithambile | +LC | Unyango lokugqibela lobushushu lulandelwa ngumzobo ofanelekileyo ukudlula (ukunciphisa indawo kancinci). |

| Ukubanda kunye noxinzelelo kuthomalalisiwe | +SR | Emva kokuba umzobo wokugqibela ubanda, iityhubhu ziyathomalaliswa kuxinzelelo kwindawo elawulwayo. |

| I-annealed ethambileyo | +A | Emva komzobo wokugqibela wokubanda, iityhubhu ziyathambathwa kwindawo elawulwayo. |

| Iqhelekile | +N | Emva komzobo wokugqibela wokubanda, iityhubhu ziyalungiswa ngendlela eqhelekileyo umoya olawulwayo. |

| a: Ngokuhambelana ne-EN10027–1. | ||

Iityhubhu zentsimbi engenamthungo ze-EN 10305 Ulwakhiwo lweekhemikhali

II-EN 10305Iityhubhu zenziwe ngeendidi zentsimbi ezikumgangatho ophezulu. Apha ngezantsi kukho isishwankathelo seendidi zezinto ezisemgangathweni kunye nokwakheka kwazo kweekhemikhali:

Itheyibhile 2 — Ukwakhiwa kweekhemikhali (uhlalutyo lwe-cast)

| Ibanga lentsimbi | % ngobunzima | ||||||

| Igama lentsimbi | Intsimbi | C | Si | Mn | P | Sa | Aliyonkeb |

| inombolo | |||||||

| E215 | 1.0212 | 0,10 | 0,05 | 0,70 | 0,025 | 0,025 | 0,025 |

| E235 | 1.0308 | 0,17 | 0,35 | 1,20 | 0,025 | 0,025 | 0,015 |

| E355 | 1.0580 | 0,22 | 0,55 | 1,60 | 0,025 | 0,025 | 0,020 |

| Izinto ezingacatshulwanga kule theyibhile (kodwa jonga umbhalo osemazantsib) aziyi kongezwa ngabom kwintsimbi ngaphandle kwesivumelwano somthengi, ngaphandle kwezinto ezinokongezwa ngenjongo yokususa i-oxidation kunye/okanye ukubopha i-nitrogen. Onke amanyathelo afanelekileyo aya kuthathwa ukuthintela ukongezwa kwezinto ezingafunekiyo ezivela kwinkunkuma okanye kwezinye izinto ezisetyenziswa kwinkqubo yokwenza intsimbi. | |||||||

| Jonga ukhetho 2. b Le mfuneko ayisebenzi xa intsimbi iqulethe inani elaneleyo lezinye izinto ezibopha initrogen, ezifana neTi, Nb okanye V. Ukuba kongezwe, umxholo wezi zinto uya kuxelwa kuxwebhu lokuhlola. Xa usebenzisa i-titanium, umenzi uya kuqinisekisa ukuba (Al + Ti/2) ≥ 0,020. | |||||||

Ukhetho 2: Kwimigangatho yentsimbi i-E235 kunye ne-E355, umxholo wesalfure olawulwayo ophakathi kwe-0,015% ukuya kwi-0,040% ucacisiwe ukuxhasa ukusebenza kakuhle komatshini. Kuya kufunyanwa ngokufaka isinyithi kwi-resulphurization emva kokukhupha i-sulphurization ephezulu okanye ngokusebenzisa inkqubo ye-oxygen ephantsi.

Ukhetho 3: Ulwakhiwo lweekhemikhali lodidi oluchaziweyo lwentsimbi kufuneka lube lolufanelekileyo kwi-hot-dip galvanizing (jonga umz. EN ISO 1461 okanye EN ISO 14713-2 ukuze ufumane isikhokelo).

Itheyibhile 3 kunye neTheyibhile A.2 zichaza ukuphambuka okuvumelekileyo kohlalutyo lwemveliso kwimida echaziweyo kuhlalutyo lwe-cast olunikiweyo kwiTheyibhile 2 kunye neTheyibhile A.1

Itheyibhile 3 — Ukuphambuka okuvumelekileyo kohlalutyo lwemveliso kwimida echaziweyo kuhlalutyo lwe-cast olunikiweyo kwiTheyibhile 2

| I-elementi | Ixabiso elilinganiselweyo le-cast | Ukuphambuka okuvumelekileyo kohlalutyo lwemveliso |

| C | ≤0,22 | +0,02 |

| Si | ≤0,55 | +0,05 |

| Mn | ≤1,60 | +0,10 |

| P | ≤0,025 | +0,005 |

| S | ≤0,040 | ±0,005 |

| Al | ≥0,015 | -0,005 |

Iityhubhu zentsimbi engenamthungo ze-EN 10305 Iipropati zoomatshini

Iimpawu zoomatshini zeI-EN 10305Iityhubhu zentsimbi ezingenamthungo, ezilinganiswa kubushushu begumbi, zezi zilandelayo. La maxabiso axhomekeke kwinqanaba lentsimbi kunye nemeko yokuhanjiswa:

Itheyibhile 4 — Iimpawu zoomatshini kubushushu begumbi

| Ibanga lentsimbi | Amaxabiso aphantsi kwimeko yokuhanjiswaa | ||||||||||||

| +Cb | +LCb | +SR | +Ac | +N | |||||||||

| Intsimbi | Intsimbi | Rm | A | Rm | A | Rm | ReH | A | Rm | A | Rm | ReHd | A |

| igama | inombolo | I-MPa | % | I-MPa | % | I-MPa | I-MPa | % | I-MPa | % | I-MPa | I-MPa | % |

| E215 | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 ukuya ku-430 | 215 | 30 |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | 340 ukuya ku-480 | 235 | 25 |

| E355 | 1.058 | 640 | 4 | 580 | 7 | 580 | 450e | 10 | 450 | 22 | 490 ukuya ku-630 | 355 | 22 |

| u-Rm: amandla okutyhafa; ReH: amandla aphezulu okuvelisa (kodwa jonga ku-11.1); A: ukwandiswa emva kokuqhekeka. Ngeempawu zemeko yokuhanjiswa jonga kuTheyibhile 1 | |||||||||||||

| b Ngokuxhomekeke kwinqanaba lomsebenzi obandayo kwi-finishing pass, amandla okukhupha anokuba phezulu kakhulu njengamandla okutsalwa. Ngeenjongo zokubala, kucetyiswa ulwalamano olulandelayo: —kwimeko yokuhanjiswa +C: ReH≥0,8 Rm; —kwimeko yokuhanjiswa +LC: ReH≥0,7 Rm. | |||||||||||||

| c Ngeenjongo zokubala, olu lwalamano lulandelayo luyacetyiswa: ReH≥0,5 Rm. | |||||||||||||

| d Kwiityhubhu ezinobubanzi obungaphandle obuyi-≤30mm kunye nobukhulu bodonga obuyi-≤3mm i-ReHamaxabiso aphantsi angama-10MPa kunamaxabiso anikwe kule theyibhile. | |||||||||||||

| e Kwiityhubhu ezinobubanzi obungaphandle>160mm: ReH≥420MPa. | |||||||||||||

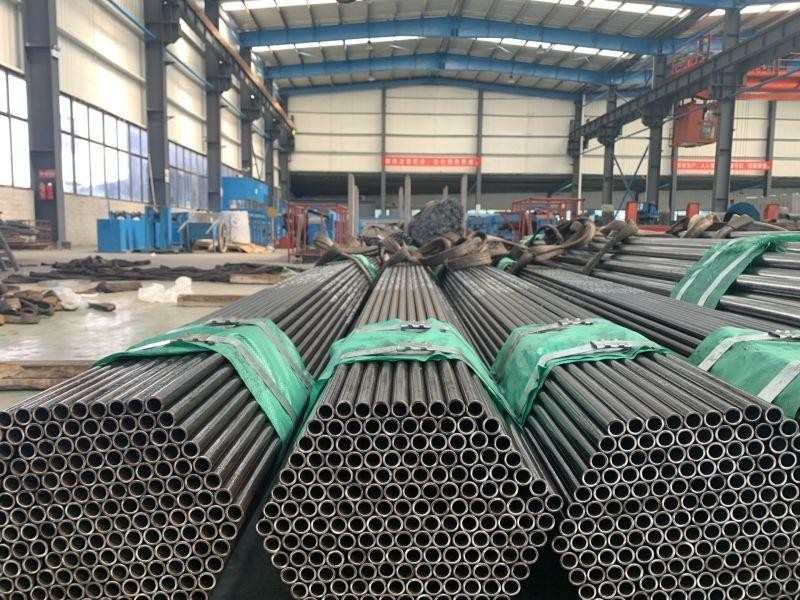

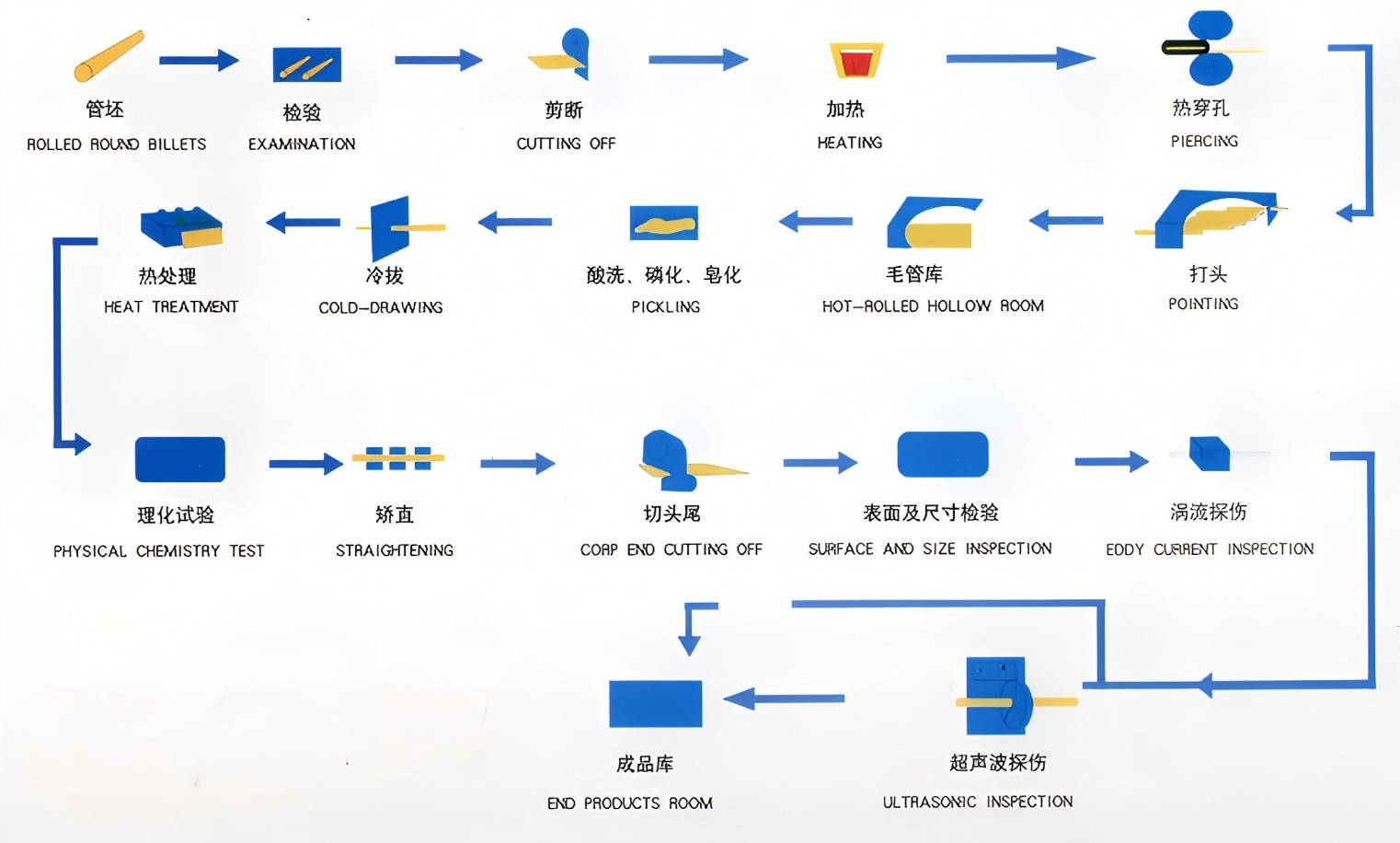

Inkqubo yokwenziwa kweetyhubhu zentsimbi engenamthungo ye-EN 10305

I-Womic Steel isebenzisa iindlela zokuvelisa eziphambili ukuvelisaIityhubhu zentsimbi ezingenamthungo ze-EN 10305, ukuqinisekisa iimveliso ezisemgangathweni ophezulu, ezenziwe ngobuchule obuchanekileyo. Le nkqubo ibandakanya la manqanaba aphambili alandelayo:

- Ukukhethwa kweeBillet kunye nokuhlolwa:

Inkqubo yokuvelisa iqala ngeebhilethi zentsimbi ezikumgangatho ophezulu, ezihlolwe kakuhle ukuqinisekisa ukuhambelana kunye nokuhambelana neenkcukacha zezinto eziphathekayo. - Ukufudumeza nokubhoboza:

Iibhilethi zifudunyezwa kubushushu obufanelekileyo zize zihlatywe ukuze zenze umbhobho ongenanto, zilungiselela ukuba ziphinde zimile. - Ukuqengqeleka Okushushu:

Iibhilethi ezingenanto ziyaqengqeleka zishushu ukuze zibumbe ityhubhu, zilungisa ubukhulu bemveliso yokugqibela. - Umzobo obandayo:

Iipayipi eziqengqelekayo ezishushu zitsalwa kubanda ngokusebenzisa iintsimbi phantsi kweemeko ezilawulwayo ukuze kufumaneke ububanzi obuchanekileyo kunye nobukhulu bodonga. - Ukukha:

Emva kokutsalwa okubandayo, iityhubhu ziyacolwa ukuze kususwe naluphi na ulusu lomphezulu okanye iileya ze-oxide, ukuqinisekisa ukuba umphezulu ucocekile kwaye uthambile. - Unyango lobushushu:

Ezi tyhubhu zisetyenziswa kwiinkqubo zokunyanga ubushushu ezifana nokutsalwa kwesinyithi, nto leyo ephucula iimpawu zazo zoomatshini kwaye iqinisekise ukuba ziyafana. - Ukulungisa nokusika:

Iityhubhu zilungiswa kwaye zinqunyulwe ngobude obufunekayo, zigcina ukulingana kunye nokuchaneka. - Ukuhlolwa noVavanyo:

Uhlolo oluqatha, oluquka ukuhlolwa kobukhulu, uvavanyo loomatshini, kunye novavanyo olungatshabalalisiyo (NDT), lwenziwa ukuqinisekisa imigangatho ephezulu yomgangatho.

Uvavanyo kunye nokuhlolwa

I-Womic Steel iqinisekisa amanqanaba aphezulu okuqinisekiswa komgangatho kunye nokulandeleka ngokusebenzisa iinkqubo ezibanzi zovavanyo lweIityhubhu zentsimbi ezingenamthungo ze-EN 10305Ezi ziquka:

- Uvavanyo lweMilinganiselo:

Ukulinganiswa kobubanzi bangaphandle, ubukhulu bodonga, ubude, ukujiya, kunye nokuthe tye. - Uvavanyo lweMishini:

Ibandakanya uvavanyo lokuxinana, uvavanyo lokuchaphazeleka, kunye novavanyo lobunzima ukuqinisekisa amandla afunekayo kunye nokuguquguquka. - Uvavanyo Olungonakalisiyo (NDT):

Uvavanyo lwangoku lwe-Eddy ukuze kufunyanwe iziphene zangaphakathi, uvavanyo lwe-ultrasonic (UT) lokujonga ubukhulu bodonga kunye nokuqina kwesakhiwo. - Uhlalutyo lweeKhemikhali:

Ukwakhiwa kwezinto kuqinisekiswa kusetyenziswa iindlela ze-spectrographic ukuqinisekisa ukuba izinto ziyahlangabezana neemfuno ezifunekayo. - Uvavanyo lwe-Hydrostatic:

Umbhobho uvavanywa uxinzelelo lwangaphakathi ukuqinisekisa ukuba unako ukumelana noxinzelelo olusebenzayo ngaphandle kokusilela.

Ulawulo lweLebhu kunye noMgangatho

I-Womic Steel isebenzisa ilebhu yanamhlanje exhotyiswe ngezixhobo zovavanyo eziphambili ukuze yenze uhlolo olunzulu lomgangatho. Iqela lethu lobuchwephesha lenza uhlolo oluqhelekileyo kwibhetshi nganyeIityhubhu zentsimbi ezingenamthungo ze-EN 10305ukuqinisekisa ukuthotyelwa kwemigangatho engqongqo yamazwe ngamazwe. Sikwasebenzisana neearhente zovavanyo zamaqela esithathu ukubonelela ngoqinisekiso oluzimeleyo lomgangatho wepayipi.

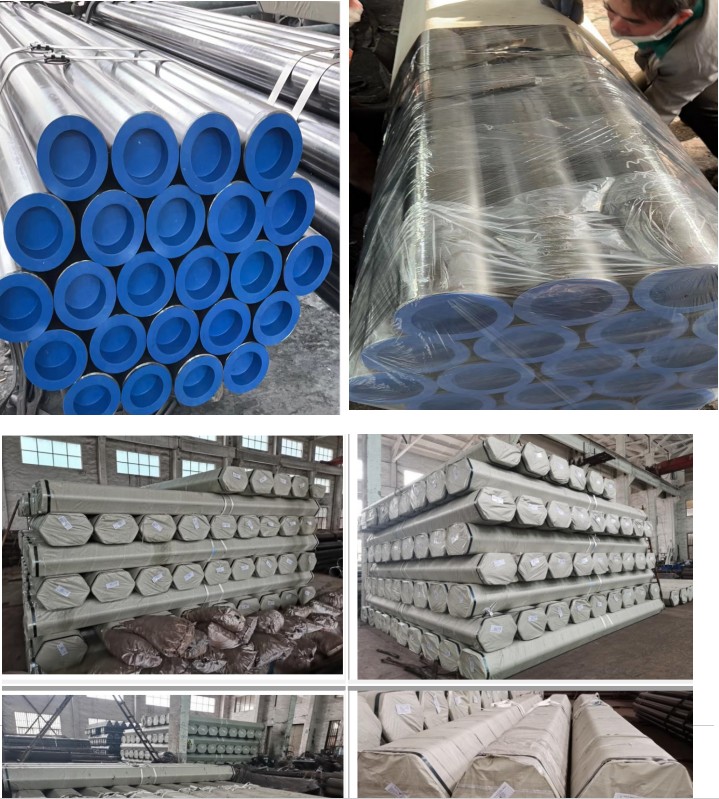

Ukupakisha

IIityhubhu zentsimbi ezingenamthungo ze-EN 10305zipakishwe ngononophelo ukuqinisekisa ukuthuthwa kwazo kunye nokuziswa kwazo ngokukhuselekileyo. Ukupakisha kuquka:

- Ukwaleka okuKhuselekileyo:

Ityhubhu nganye igqunywe ngumaleko okhuselayo wokulwa nokugqwala ukuthintela ukugqwala kunye nokubola ngexesha lokuthuthwa nokugcinwa. - Ii-Caps zokuphela:

Izigqubuthelo zeplastiki okanye zesinyithi zifakwa kuzo zombini iziphelo zeetyhubhu ukuthintela ungcoliseko, ukufuma, okanye umonakalo womzimba. - Ukuhlanganisa:

Iityhubhu zibotshelelwe ndawonye ngokukhuselekileyo ngeentambo zentsimbi okanye iibhanti zeplastiki ukugcina uzinzo kunye nokuthintela ukushukuma ngexesha lokuthuthwa. - Ukusonga ngokunciphisa:

Iibhanti zisongelwa kwifilimu yokunciphisa ukuze zikhusele iityhubhu eluthulini, ukungcola, nezinye izinto ezisingqongileyo. - Ukuchongwa kunye nokuLebhelishwa:

Iphakheji nganye ibhalwe iinkcukacha zemveliso, kuquka umgangatho wentsimbi, ubukhulu, inombolo yebhetshi, ubungakanani, kunye nayo nayiphi na imiyalelo ekhethekileyo yokuphatha.

Uthutho

I-Womic Steel iqinisekisa ukuhanjiswa kweenkonzo kwihlabathi liphela ngexesha elifanelekileyo nangokuthembekileyoIityhubhu zentsimbi ezingenamthungo ze-EN 10305ngeendlela zothutho ezilandelayo:

Ukuthutha Ulwandle:

Kwiimpahla ezithunyelwa kwamanye amazwe, iityhubhu zifakwa kwiikhonteyina okanye kwiirakhi ezisicaba kwaye zithunyelwa nakweyiphi na indawo emhlabeni jikelele.

Uthutho lweZitimela kunye neNdlela:

Kwimithwalo yasekhaya neyengingqi, iityhubhu zilayishwa ngokukhuselekileyo kwiilori ezisicaba okanye kwiikhonteyina kwaye zithuthwa ngendlela okanye ngololiwe.

Ulawulo lweMozulu:

Ukuba kuyimfuneko, singalungiselela ukuthuthwa okulawulwa yimozulu ukukhusela iityhubhu kwiimeko ezimandundu zendalo.

Amaxwebhu kunye ne-inshurensi:

Amaxwebhu apheleleyo okucoca impahla yerhafu, ukuthunyelwa, kunye nokulandelela ayabonelelwa, kwaye i-inshurensi ingalungiselelwa ukuthunyelwa kwamanye amazwe ukukhusela umonakalo okanye ilahleko enokubakho.

Iingenelo zokukhetha intsimbi yeWomic

Ukuvelisa ngokuchanekileyo:

Silawula ngokungqongqo zonke iinkqubo zokuvelisa ukuze sihlangabezane nobukhulu obuchanekileyo bokunyamezelana.

Ukwenziwa ngokwezifiso:

Iindlela eziguquguqukayo zobude beetyhubhu, unyango lomphezulu, kunye nokupakishwa ngokusekelwe kwiinkcukacha zabathengi.

Uvavanyo olupheleleyo:

Uvavanyo oluqinileyo luqinisekisa ukuba ityhubhu nganye iyahlangabezana nemigangatho efunekayo yoomatshini, iikhemikhali kunye nobukhulu.

Ukuhanjiswa kweHlabathi:

Ukuhanjiswa okuthembekileyo nokwangexesha elifanelekileyo, naphi na apho iprojekthi yakho ikhoyo.

Iqela elinamava:

Iinjineli kunye neengcali ezinobuchule ziqinisekisa umgangatho ophezulu wemveliso kunye nemigangatho yenkonzo yabathengi.

Isiphelo

I-Womic Steel'sIityhubhu zentsimbi ezingenamthungo ze-EN 10305zenzelwe ukubonelela ngamandla aphezulu, ukuthembeka, kunye nokuchaneka kwiintlobo ngeentlobo zezicelo ezifuna amandla. Ngokuzibophelela kwethu ekuveliseni umgangatho, imveliso ephucukileyo, kunye nokwaneliseka kwabathengi, singamaqabane athembekileyo kwizisombululo zeetyhubhu ezingenamthungo kwihlabathi liphela.

Khetha iWomic Steel kwishishini lakhoIityhubhu zentsimbi ezingenamthungo ze-EN 10305kwaye ufumane amava eemveliso ezisebenza kakuhle ezixhaswa bubuchule obungenakuthelekiswa nanto.

Ukuze ufumane iinkcukacha ezithe vetshe, nceda unxibelelane nathi ngqo:

Iwebhusayithi: www.womicsteel.com

I-imeyile: sales@womicsteel.com

Umnxeba/i-WhatsApp/i-WeChat: Victor: +86-15575100681 okanye uJack: +86-18390957568