Ingcaciso yeMveliso

Umbhobho wentsimbi echanekileyo luhlobo lwentsimbi yekhabhoni, intsimbi ye-alloy okanye imibhobho yentsimbi engatyiwayo enobukhulu obuphezulu. Ihlala iveliswa kwiinkqubo zokuqengqeleka okushushu okanye ezitsalwa ngokubandayo (ukuqengqeleka okubandayo). Ngoko ke imibhobho echanekileyo yimibhobho engenamthungo, eminye imibhobho echanekileyo yimibhobho yentsimbi edityanisiweyo.

Iipayipi ezichanekileyo eziyilwe ngeenzuzo ezininzi:

● Umphezulu wangaphakathi nangaphandle akukho ngubo;

● Iityhubhu ezichanekileyo zinokuthwala uxinzelelo oluphezulu, akukho kuvuza;

● Ukunganyamezelani okungqongqo;

● Phakamisa kakuhle

● Akukho tshintsho ekugobeni okubandayo, akukho mifantu ngexesha lovavanyo lokuvutha kunye novavanyo lokucanda.

Iityhubhu zemibhobho echanekileyo ezisetyenziswa kakhulu ekuveliseni iindawo zomoya kunye nezinto ze-hydraulic

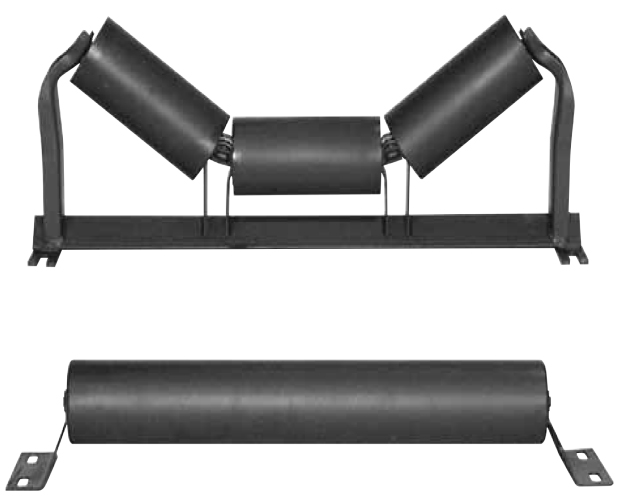

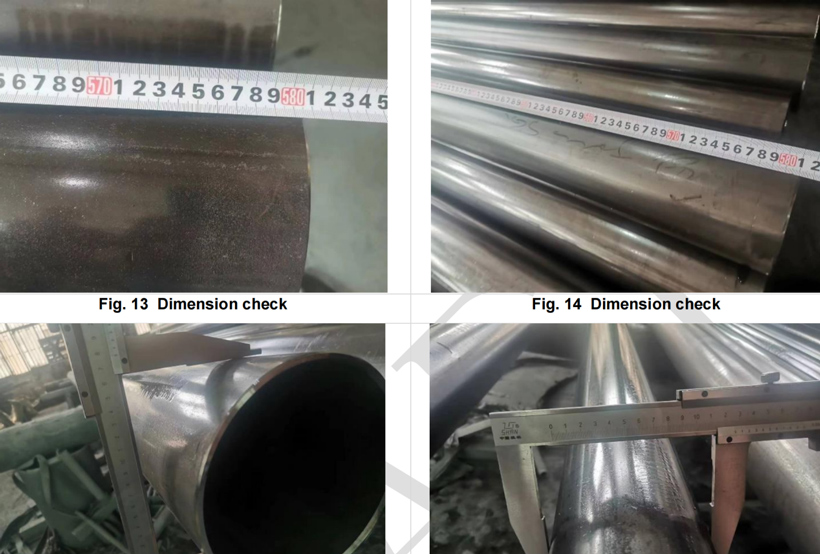

Ububanzi bangaphakathi nangaphandle bunokulawula ngaphakathi kwe-+/- 0.01 mm. Njengesiqinisekiso samandla okulwa nokugoba kunye namandla e-torque, ubunzima bombhobho ochanekileyo bulula. Ingasetyenziswa kakhulu ekuveliseni iindawo zoomatshini abachanekileyo kunye nesakhiwo sobunjineli, kwaye ikwasetyenziswa kakhulu ukuvelisa iintlobo ngeentlobo zezixhobo zemveli, iibharele, iigobolondo, iibheringi, iirola zokuhambisa, ii-sugar mills njl.njl.

Iipayipi zentsimbi ezichanekileyo kakhulu kunye neetyhubhu esizivelisileyo zisetyenziswa kakhulu kumenzi weeroller ezingasebenziyo kangangeminyaka emininzi.

Kuvuyisa kakhulu ukwazi ukuba inkampani yakho ikwaqhuba kakuhle kumenzi we-Idler Roller, kuba sinabathengi abaninzi abenza ishishini elifanayo nelakho.

Iipayipi zentsimbi ezichanekileyo eziveliswe yi-US uluhlu kunye nolawulo lokunyamezelana njengoko kuboniswe ngezantsi:

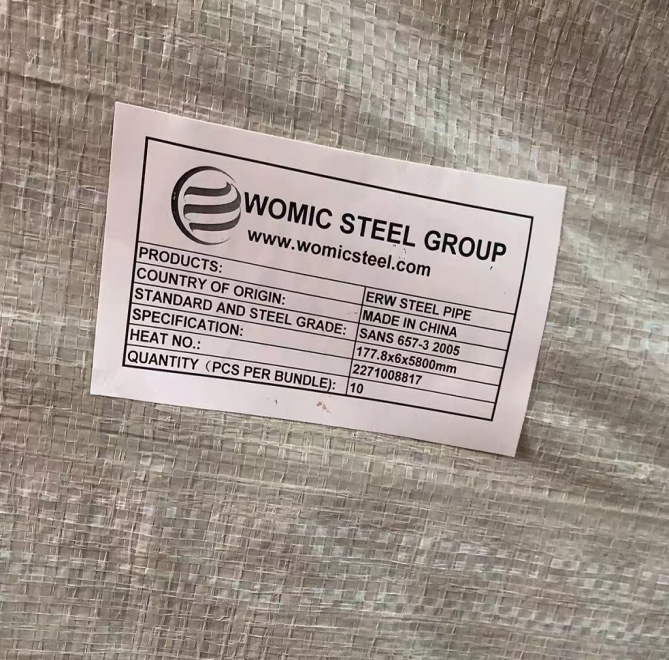

Ububanzi bemveliso eqhelekileyo:101.6mm, 108mm, 127mm, 133.1mm, 152.4mm, 158.8mm, 165.1mm, 177.8mm, 219.1mm njl., nazo ziyafumaneka ngobukhulu obulungiselelwe wena.

Ulawulo lokunyamezelana:

I-OD 101.6mm ~ 127mm, Ukunyamezelana kwe-OD okuchaziweyo ± 0.1 mm, Ukuma kwe-Ovality 0.2 mm;

I-OD 133.1mm ~ 219.1mm, Ukunyamezelana kwe-OD okuchaziweyo ±0.15mm, Ukuma kwe-Ovality 0.3 mm;

Ubukhulu bodonga:

± 0.1 mm yobukhulu bodonga lombhobho obungezantsi kwaye buquka i-4.5mm,

± 0.1 mm ubukhulu bodonga lombhobho obungaphezulu kwe-4.5mm.

Ukuqondakala:

Akufuneki idlule i-1 kwi-1000 (ilinganiswe embindini wetyhubhu).

Ixesha lemveliso lihlala liziintsuku ezingama-20, Ndijonge phambili kwimpendulo yakho efudumeleyo nemibuzo, enkosi

Iinkcukacha

| Iphepha leeNkcukacha zeMveliso yeMibhobho yeNsimbi yeWomic Steel Precision | |||||||||

| Ityhubhu Engqukuva Yabahambisi Abangakhathaliyo Nabaqengqelekiyo | Ityhubhu OD [mm] | Ityhubhu ID [mm] | Udonga Th [mm] | Ubunzima kg/m | I-SANS 657-3 | Ukunyamezelana kwe-OD | Ukunyamezelana kwe-WT | Ukunyamezela Ubude | Ukuqanda UMax. |

| 101.60 | 94.60 | 3.5 | 8.46 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 114.00 | 107.00 | 3.5 | 9.53 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 133.10 | 126.10 | 3.5 | 11.18 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 133.10 | 125.10 | 4.0 | 12.73 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 119.4 | 3.8 | 11.54 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 118.00 | 4.5 | 13.59 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 117.00 | 5.0 | 15.04 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 115.00 | 6.0 | 17.90 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 120.00 | 3.5 | 10.65 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 144.40 | 4.0 | 14.63 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 143.40 | 4.5 | 16.41 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 142.40 | 5.0 | 18.17 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 144.40 | 4.0 | 14.63 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 140.40 | 6.0 | 21.65 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 158.80 | 149.80 | 4.5 | 17.12 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 159.00 | 151.00 | 4.0 | 15.28 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 159.00 | 150.00 | 4.5 | 17.14 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 177.80 | 165.80 | 6.0 | 25.41 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 193.70 | 181.70 | 6.0 | 27.76 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 157.00 | 4.0 | 15.87 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 153.00 | 6.0 | 4.04 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 165.00 | 156.00 | 4.5 | 17.80 | Inxalenye 3 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 97.60 | 2.0 | 4.91 | -- | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 96.00 | 2.8 | 6.82 | -- | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 127.00 | 123.00 | 2.0 | 6.16 | -- | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 152.40 | 146.80 | 2.8 | 10.32 | -- | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| IZIXHOBO ZOKWAKHIWA KWESITHUBHU ESIZINGQONGILEYO | Ityhubhu OD [mm] | Ityhubhu ID [mm] | Udonga Th [mm] | Ubunzima kg/m | I-SANS 657-3 | Ukunyamezelana kwe-OD | Ukunyamezelana kwe-WT | Ukuqanda UMax. | |

| 31.80 | 25.80 | 3.0 | 2.13 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 48.40 | 42.40 | 3.0 | 3.36 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 63.50 | 57.50 | 3.0 | 4.47 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 76.20 | 69.20 | 3.5 | 6.27 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 76.20 | 67.20 | 4.5 | 7.95 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 84.90 | 2.0 | 4.28 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 82.90 | 3.0 | 6.35 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 81.90 | 3.5 | 7.37 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 88.90 | 78.90 | 5.0 | 10.34 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 95.60 | 3.0 | 7.29 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| 101.60 | 92.60 | 4.5 | 10.77 | Inxalenye 1 | ± 0.1 mm | ± 0.1 mm | ± 20mm | 0.2 mm | |

| Ukulungela Akufanelanga kudlule i-1mm ngobude obuyi-1200mm (bulinganiswe embindini wetyhubhu). | |||||||||

| ICOCEKILE, AYINASIKALI SOKUGQIBELA NOMGQA OKANYE NAYIPHI NA EZINYE IZINTO, EZINJENGEOYILE, IGREASE Njl. | |||||||||

Imigangatho kunye neBanga

I-SANS 657-3, iityhubhu ezichanekileyo zokwenza iirola zokuhambisa.

EN 10305-1, Iityhubhu ezichanekileyo ze-Heat exchanger kunye ne-condenser.

I-DIN 2393, iityhubhu zentsimbi echanekileyo edibeneyo Ityhubhu yentsimbi yenkqubo ye-hydraulic

BS6323/4, Imibhobho echanekileyo kushishino lombane,

I-NF A 49-310, i-NF A 49-312, iipayipi ezichanekileyo zoomatshini bokwakha

I-UNI 7945, iityhubhu zentsimbi echanekileyo engenamthungo. Udidi lwentsimbi. Fe 280

STN/ČSN 42 6711, Iityhubhu zentsimbi ezingenamthungo ezichanekileyo

STN/ČSN 42 6712, Iityhubhu zentsimbi ezingenamthungo ezichanekileyo

Iipayipi ezisemgangathweni zaseRashiya zePN-H 74240, PN-H 74220

Iityhubhu zentsimbi ezichanekileyo ze-ASTM A450 ukuya kwi-A519, i-Ferritic Alloy / i-Austentic Alloy

I-GOST 8734, 9567, 12132 Iityhubhu zentsimbi echanekileyo eyenziwe ngokubandayo engenamthungo

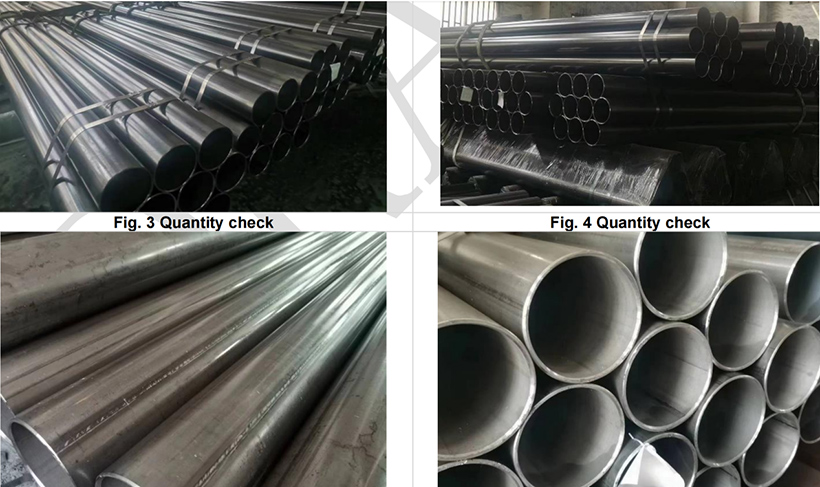

Ulawulo lwemeko

Ukujonga Izinto Ezingavulwanga, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Uvavanyo loxinzelelo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lwempembelelo, Uvavanyo lwe-DWT, Uvavanyo lwe-NDT, Uvavanyo lwe-Hydrostatic, Uvavanyo loBulukhuni…..

Ukumakisha, Ukupeyinta ngaphambi kokuhanjiswa.

Ukupakisha kunye nokuthumela

Indlela yokupakisha imibhobho yentsimbi ibandakanya ukucoca, ukuhlanganisa, ukusonga, ukubopha, ukubopha, ukulebhelisha, ukufaka iipalethi (ukuba kuyimfuneko), ukufaka kwiikhonteyina, ukuvala, ukuthutha, kunye nokukhupha izinto. Iintlobo ngeentlobo zemibhobho yentsimbi kunye nezixhobo ezineendlela ezahlukeneyo zokupakisha. Le nkqubo ibanzi iqinisekisa ukuba imibhobho yentsimbi ithunyelwa kwaye ifika kwindawo eya kuyo ikwimeko efanelekileyo, ilungele ukusetyenziswa kwayo.

Ukusetyenziswa kunye neSicelo

Iipayipi zentsimbi zisebenza njengomqolo wobunjineli banamhlanje bemizi-mveliso nobokwakha, zixhasa uluhlu olubanzi lwezicelo ezinegalelo kuphuhliso lwentlalo kunye noqoqosho kwihlabathi liphela.

Iipayipi zentsimbi kunye nezixhobo esizivelisileyo zeWomic Steel zisetyenziswa kakhulu kwimibhobho yepetroli, igesi, amafutha kunye namanzi, iiprojekthi zokwakha izibuko lolwandle kunye nokwakha, ukugrumba, iiprojekthi zokwakha intsimbi, ukupakisha kunye neebhulorho, kunye neetyhubhu zentsimbi ezichanekileyo zokuvelisa i-conveyor roller, njl.njl.