Ingcaciso yeMveliso

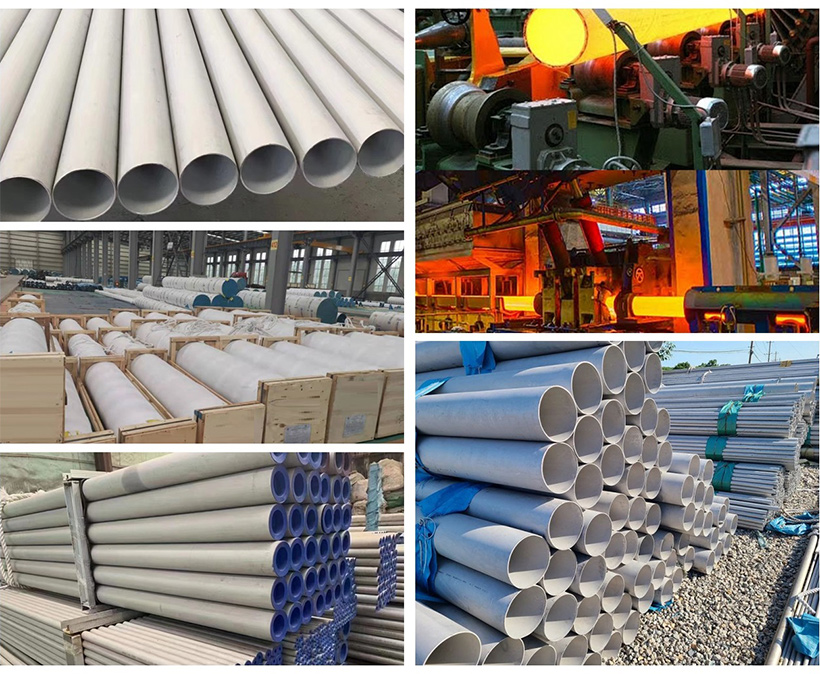

Iipayipi zentsimbi engenamthungo ziyinxalenye ebalulekileyo kwizicelo zanamhlanje zoshishino, ezidume ngokuqina kwazo okugqwesileyo, ukumelana nokugqwala, kunye nokwakhiwa kwazo okungenamthungo. Ziqulathe i-alloy ekhethekileyo yentsimbi, i-chromium, kunye nezinye izinto ezifana ne-nickel kunye ne-molybdenum, ezi pipes zibonisa amandla angenakuthelekiswa nanto kunye nobude bexesha.

Inkqubo yokuvelisa engenamthungo ibandakanya ukukhupha iibhilethi zentsimbi eziqinileyo ukuze zenze iityhubhu ezingenanto ngaphandle kwamalungu adibeneyo. Le ndlela yokwakha isusa iindawo ezibuthathaka ezinokubakho kwaye iphucula ukuqina kwesakhiwo, okwenza iipayipi zentsimbi engenamthungo ezingenamthungo zithembeke kakhulu kwiindlela ezahlukeneyo zokusebenza.

Iimpawu eziphambili:

Ukumelana nokugqwala:Ukufakwa kwe-chromium kudala umaleko we-oxide okhuselayo, okhusela imibhobho ekungcoleni nasekugqwaleni nakwiindawo ezinzima.

Amanqanaba ahlukeneyo:Iipayipi ezingenamthungo zifumaneka kwiindidi ezahlukeneyo ezifana ne-304, 316, 321, kunye ne-347, nganye yenzelwe ukusetyenziswa okuthile ngenxa yokwahluka kokwakheka kweekhemikhali kunye neempawu zoomatshini.

Izicelo ezibanzi:Ezi mbhobho zisetyenziswa kumacandelo amaninzi, kuquka ioyile negesi, ukucubungula iikhemikhali, ukutya neziselo, amayeza, iimoto, kunye nokwakha. Ukuziqhelanisa kwazo neemeko ezahlukeneyo kunye nezinto kugxininisa ukuguquguquka kwazo.

Ubungakanani kunye nokugqitywa:Iipayipi zentsimbi engenamthungo ziza ngobukhulu obahlukeneyo, zilungele iimfuno ezahlukeneyo. Ezi pipes zinokuba nokugqitywa okuhlukeneyo komphezulu, ukusuka ekugqityweni okukhazimlisiweyo ukuya ekugqityweni komatshini, ngokusekelwe kwiimfuno zokusetyenziswa.

Ukufakelwa kunye nokugcinwa:Uyilo olungenamthungo lwenza kube lula ukufakela ngelixa ukumelana kwemibhobho nokugqwala kunciphisa iimfuno zokugcinwa kwayo, nto leyo enegalelo ekongeni iindleko.

Ukususela ekwenzeni lula ukuthuthwa kweoyile negesi ukuya ekuvumeleni ukuhanjiswa kweekhemikhali ngokukhuselekileyo kunye nokugcina ubunyulu beemveliso zamayeza, iipayipi zentsimbi engenamthungo engenasici zidlala indima ebalulekileyo ekubumbeni amashishini kwihlabathi liphela. Ukudibana kwazo namandla, ukuqina, kunye nokumelana nezinto ezingqongileyo kuzenza zibe yimpahla ebalulekileyo kubunjineli banamhlanje kunye neziseko zophuhliso.

Iinkcukacha

| I-ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njl.njl.... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njl... |

| I-DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njl... |

| I-JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB njl.njl.... |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Intsimbi engagqwaliyo yase-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Intsimbi engagqwali ephindwe kabini:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetyenziswa:Amashishini okuvelisa izixhobo zePetroleum, iiKhemikhali, igesi yendalo, amandla ombane kunye nezixhobo zoomatshini. |

| NB | Ubungakanani | OD mm | I-SCH40S mm | I-SCH5S mm | I-SCH10S mm | I-SCH10 mm | I-SCH20 mm | I-SCH40 mm | I-SCH60 mm | XS/80S mm | I-SCH80 mm | I-SCH100 mm | I-SCH120 mm | I-SCH140 mm | I-SCH160 mm | I-SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 |

Imigangatho kunye neBanga

| Umgangatho | Amanqanaba eNsimbi |

| I-ASTM A312/A312M: Iipayipi ze-Austenitic Stainless Steel ezingasebenzi kakuhle, ezidityanisiweyo, nezibandayo kakhulu | 304, 304L, 310S, 310H, 316, 316L, 321, 321H njl.njl... |

| I-ASTM A213: Ibhoyila yentsimbi ye-ferritic ne-austenitic engenamthungo, i-superheater, kunye neetyhubhu zokutshintsha ubushushu | TP304, TP304L, TP316, TP316L, TP321.TP347 njl... |

| I-ASTM A269: Iityhubhu zentsimbi engagqwaliyo ezidityanisiweyo nezingenamthungo zenkonzo eqhelekileyo | TP304, TP304L, TP316, TP316L, TP321.TP347 njl... |

| I-ASTM A789: Iityhubhu zentsimbi engagqwaliyo ze-ferritic/austenitic ezingenamthungo nezidibeneyo zenkonzo eqhelekileyo | S31803 (Intsimbi engagqwaliyo yeDuplex) I-S32205 (intsimbi engagqwaliyo yeDuplex) |

| I-ASTM A790: Umbhobho wentsimbi engenamthungo nedibeneyo ye-ferritic/austenitic yenkonzo yokubola ngokubanzi, inkonzo yobushushu obuphezulu, kunye nemibhobho yentsimbi engenamthungo ephindwe kabini. | S31803 (Intsimbi engagqwaliyo yeDuplex) I-S32205 (intsimbi engagqwaliyo yeDuplex) |

| I-EN 10216-5: Umgangatho waseYurophu weetyhubhu zentsimbi engenamthungo zeenjongo zoxinzelelo | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njl. njl.... |

| I-DIN 17456: Umgangatho waseJamani weThubhu yeNtsimbi engenamthungo ejikelezayo | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njl. njl.... |

| I-JIS G3459: Umgangatho wezoShishino waseJapan weeMibhobho zeNtsimbi engaGciniyo zokuxhathisa ukuGqwala | I-SUS304TB, i-SUS304LTB, i-SUS316TB, i-SUS316LTB njl... |

| GB/T 14976: Umgangatho weSizwe waseTshayina weeMibhobho zeNtsimbi engenamthungo zoThutho oluNyulu | 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Intsimbi engagqwaliyo yase-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Intsimbi engagqwaliyo ephindwe kabini:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetyenziswa: I-Petroleum, iKhemikhali, igesi yendalo, umbane kunye namashishini okuvelisa izixhobo zoomatshini. | |

Inkqubo yoMveliso

Inkqubo yokuqengqeleka okushushu (ipayipi yentsimbi engenamthungo ekhutshiweyo):

Ityhubhu ejikelezayo →ukufudumeza →ukugqobhoza →ukuqengqeleka okuqengqelekayo okuneziroli ezintathu, ukuqengqeleka okuqhubekayo okanye ukukhupha ityhubhu →ukususa ubungakanani (okanye ukunciphisa ububanzi) →ukupholisa →ukulungisa →uvavanyo lwe-hydraulic (Okanye ukufunyanwa kweziphene) →uphawu →ugcino

Inkqubo yeThubhu yentsimbi engenamthungo etsalwe ngokubandayo (eqengqelekayo):

Ityhubhu ejikelezayo →ukufudumeza →ukugqobhoza →intloko →ukuqhobosha →ukuqhobosha →ukucola →ukuoyela (ukugquma ngobhedu) →ukutsalwa ngokubanda okuhamba ngeendlela ezininzi (ukuqengqeleka okubandayo) →ukuqhobosha →unyango lobushushu →ukuthe tye →uvavanyo lwe-hydraulic (ukufunyanwa kweziphene) →Ukuphawula →Ukugcina.

Ulawulo lwemeko

Ukujonga Izinto Eziluhlaza, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lweMpembelelo, Uvavanyo lokuGqoka phakathi kwegranular, Uvavanyo lokuGqoka nokuThambatha olungonakalisiyo (UT, MT, PT), Uvavanyo loBulukhuni, Uvavanyo loxinzelelo, Uvavanyo loMxholo weFerrite, Uvavanyo lweMetallography, Uvavanyo lokuGqoka, Uvavanyo lwangoku lwe-Eddy, Uvavanyo lweTyuwa, Uvavanyo lokuxhathisa ukuGqoka, Uvavanyo lokungcangcazela, Uvavanyo lokuGqoka, Uvavanyo lokuGqoka, Uvavanyo lokuPenda nokuGqoka, Uhlolo lwamaxwebhu…..

Ukusetyenziswa kunye neSicelo

Iipayipi ezingenamthungo zentsimbi engagqwaliyo zizinto ezibalulekileyo ezisetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yokumelana kwazo nokugqwala okugqwesileyo, amandla aphezulu, kunye nokukwazi ukumelana namaqondo obushushu aphezulu. Nazi ezinye zeendlela eziphambili zokusetyenziswa kweepayipi ezingenamthungo zentsimbi engagqwaliyo:

Ishishini leoyile negesi:Iipayipi ezingenamthungo zentsimbi engagqwaliyo zisetyenziswa kakhulu ekuphononongeni ioyile negesi, ekuthuthweni nasekusetyenzweni. Zisetyenziselwa ukubopha imithombo, iipayipi, kunye nezixhobo zokucubungula ngenxa yokumelana kwazo nokugqwala kulwelo kunye neegesi.

Ushishino lweeKhemikhali:Kwinkqubo yokucubungula nokuvelisa iikhemikhali, imibhobho engenamthungo yentsimbi engagqwaliyo isetyenziselwa ukuhambisa ii-asidi, iziseko, izinyibilikisi, kunye nezinye izinto ezirhabaxa. Zinegalelo kukhuseleko nokuthembeka kweenkqubo zemibhobho.

Ishishini laMandla:Iipayipi ezingenamthungo zentsimbi engenasici zidlala indima ebalulekileyo kwimveliso yamandla, kuquka amandla enyukliya, iiseli zamafutha, kunye neeprojekthi zamandla avuselelekayo, kwiipayipi nezixhobo.

Ishishini lokutya neziselo:Ngenxa yococeko lwazo kunye nokumelana nokugqwala, imibhobho engenamthungo yentsimbi engagqwali isetyenziswa kakhulu ekulungisweni kokutya nakwimveliso yeziselo, kubandakanya ukuhanjiswa kwezinto ezimanzi, iigesi kunye nezinto zokutya.

Ishishini leMithi:Kwimveliso yamayeza kunye nemveliso yamayeza, imibhobho engenamthungo yentsimbi engagqwaliyo isetyenziselwa ukuhambisa nokuphatha izithako zamayeza, ukuhlangabezana nemigangatho yococeko kunye nomgangatho.

Ukwakhiwa kweenqanawa:Iipayipi ezingenamthungo zentsimbi engagqwaliyo zisetyenziswa ekwakheni iinqanawa zokwakha izakhiwo zeenqanawa, iinkqubo zemibhobho, kunye nezixhobo zonyango lwamanzi olwandle, ngenxa yokuchasana kwazo nokugqwala kwendalo yolwandle.

Izixhobo zokwakha nezokwakha:Iipayipi ezingenamthungo zentsimbi engagqwaliyo ezisetyenziswa ekwakheni zisetyenziselwa imibhobho yokuhambisa amanzi, iinkqubo ze-HVAC, kunye nezixhobo zesakhiwo zokuhombisa.

Ishishini leeMoto:Kwicandelo leemoto, imibhobho engenamthungo yentsimbi engagqwaliyo isetyenziswa kwiinkqubo zokukhupha umoya ngenxa yokumelana nobushushu obuphezulu kunye nokumelana nokugqwala.

Ukwembiwa kweMigodi kunye neMetallurgy:Kwimimandla yemigodi neyesinyithi, imibhobho engenamthungo yentsimbi engagqwaliyo isetyenziselwa ukuthutha i-ore, i-slurry, kunye nezisombululo zeekhemikhali.

Ngamafutshane, iipayipi ezingenamthungo zentsimbi engagqwaliyo zinokuguquguquka kwaye zibonelela ngokusebenza okuphezulu, nto leyo ezenza zifaneleke kumashishini ahlukeneyo. Zidlala indima ebalulekileyo ekuqinisekiseni ukhuseleko lwenkqubo, ukuphucula ukuthembeka kwezixhobo, kunye nokwandisa ubomi benkonzo. Usetyenziso olwahlukeneyo lufuna iipayipi ezingenamthungo zentsimbi engagqwaliyo ezineenkcazo ezithile kunye nezixhobo ukuhlangabezana neemfuno zazo ezizodwa.

Ukupakisha kunye nokuthumela

Imibhobho yentsimbi engagqwaliyo iyapakishwa kwaye ithunyelwe ngononophelo olukhulu ukuqinisekisa ukhuseleko lwayo ngexesha lokuhamba. Nantsi inkcazo yenkqubo yokupakisha nokuthumela:

Ukupakisha:

● Ukwaleka Okukhuselekileyo: Ngaphambi kokupakisha, imibhobho yentsimbi engagqwaliyo idla ngokugqunywa ngomaleko weoyile okanye ifilimu yokukhusela ukuthintela ukugqwala kunye nomonakalo womphezulu.

● Ukubopha: Imibhobho enobukhulu obufanayo kunye neenkcukacha ezifanayo ihlanganiswa ngononophelo. Ibotshelelwa kusetyenziswa imitya, iintambo, okanye iibhanti zeplastiki ukuthintela intshukumo ngaphakathi kwebhanti.

● Ii-End Caps: Ii-end caps zeplastiki okanye zesinyithi zibekwe kuzo zombini iziphelo zemibhobho ukuze zikhuseleke ngakumbi kwiziphelo zemibhobho kunye nemisonto.

● Ukugquma kunye nokugquma: Izinto zokugquma ezifana ne-foam, i-bubble wrap, okanye i-corrugated cardboard zisetyenziselwa ukubonelela ngokugquma kunye nokuthintela umonakalo ngexesha lokuthuthwa.

● Iibhokisi okanye iibhokisi zomthi: Kwezinye iimeko, imibhobho ingapakishwa kwiibhokisi zomthi okanye iibhokisi ukuze inike ukhuseleko olongezelelweyo kumandla angaphandle kunye nokuphathwa.

Ukuhambisa ngenqanawe:

● Indlela Yokuthutha: Iipayipi zentsimbi engagqwaliyo zihlala zithunyelwa kusetyenziswa iindlela ezahlukeneyo zokuthutha ezifana neelori, iinqanawa, okanye uthutho lweenqwelo-moya, kuxhomekeke kwindawo oya kuyo kunye nongxamiseko.

● Ukufakwa kwiikhonteyina: Iipayipi zinokufakwa kwiikhonteyina zokuthutha impahla ukuqinisekisa ukuba izinto zihamba ngendlela ekhuselekileyo necwangcisiweyo. Oku kukwakhusela kwiimeko zemozulu kunye nezinto ezingcolisayo zangaphandle.

● Ukubhala iilebheli kunye namaxwebhu: Iphakheji nganye ibhalwe iinkcukacha ezibalulekileyo, kubandakanya iinkcukacha, ubungakanani, imiyalelo yokuphatha, kunye neenkcukacha zendawo ekuyiwa kuyo. Amaxwebhu okuthumela alungiselelwe ukususwa kwempahla kunye nokulandelwa kwempahla.

● Ukuthobela iMithetho yezeMali: Kwimpahla ethunyelwa kwamanye amazwe, onke amaxwebhu ayimfuneko yezemali alungiselelwe ukuqinisekisa ukuba impahla ifika kakuhle kwindawo ekuyiwa kuyo.

● Ukubopha Okukhuselekileyo: Ngaphakathi kwisithuthi okanye kwisikhongozeli, imibhobho ibotshelelwe ngokukhuselekileyo ukuthintela intshukumo nokunciphisa umngcipheko wokonakala ngexesha lokuhamba.

● Ukulandelela Nokubeka Esweni: Iinkqubo zokulandelela eziphambili zingasetyenziswa ukujonga indawo kunye nemeko yokuthunyelwa ngexesha langempela.

● I-inshorensi: Ngokuxhomekeke kwixabiso lomthwalo, i-inshorensi yokuthumela impahla ingafunyanwa ukuze ihlawule ilahleko okanye umonakalo onokubakho ngexesha lokuhamba.

Ngamafutshane, iipayipi zentsimbi engagqwaliyo esizenzileyo ziya kupakishwa ngamanyathelo okukhusela kwaye zithunyelwe kusetyenziswa iindlela zokuthutha ezithembekileyo ukuqinisekisa ukuba zifika kwindawo eziya kuyo zikwimeko efanelekileyo. Iinkqubo ezifanelekileyo zokupakisha nokuthumela zinegalelo ekugqibeleleni nasekusemgangathweni kweepayipi ezihanjiswayo.