Ingcaciso yeMveliso

Iipayipi zentsimbi ezijikelezayo, ezaziwa ngokuba ziipayipi ze-helical submerged arc-welded (HSAW), luhlobo lombhobho wentsimbi olubonakaliswa yinkqubo yazo yokuvelisa eyahlukileyo kunye neempawu zesakhiwo. Ezi payipi zisetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yamandla azo, ukuqina kwazo, kunye nokuzivumelanisa nezimo. Nantsi inkcazo eneenkcukacha zeepayipi zentsimbi ezijikelezayo:

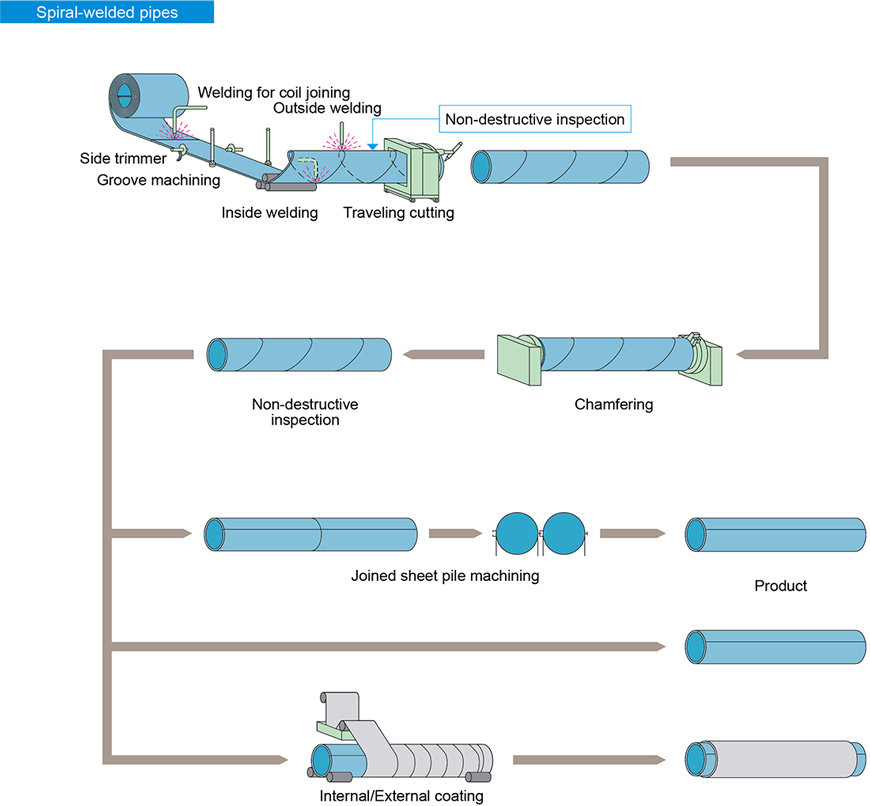

Inkqubo yoMveliso:Imibhobho yentsimbi ejikelezayo iveliswa ngenkqubo eyahlukileyo equka ukusetyenziswa kwe-coil ye-steel strip. I-strip iyavuleka ize yenziwe ibe yi-spiral shape, emva koko idityaniswe kusetyenziswa indlela ye-inferior arc welding (SAW). Le nkqubo iphumela kumthungo oqhubekayo, ojikelezayo kubude bombhobho.

Uyilo lweZakhiwo:Umthungo ojikelezayo weepayipi zentsimbi ezijikelezayo unika amandla angaphakathi, nto leyo eyenza zilungele ukumelana nemithwalo ephezulu kunye noxinzelelo. Olu yilo luqinisekisa ukusasazwa okufanayo koxinzelelo kwaye luphucula amandla ombhobho okumelana nokugoba kunye nokuguquka.

Uluhlu Lobukhulu:Iipayipi zentsimbi ezijikelezayo ziza ngobubanzi obuhlukeneyo (ukuya kuthi ga kwi-120 intshi) kunye nobukhulu, okuvumela ukuguquguquka kwizicelo ezahlukeneyo. Zifumaneka ngokubanzi ngobubanzi obukhulu xa kuthelekiswa nezinye iintlobo zeepayipi.

Izicelo:Iipayipi zentsimbi ezijikelezayo zisetyenziswa kumashishini ahlukeneyo afana neoyile negesi, unikezelo lwamanzi, ulwakhiwo, ezolimo, kunye nophuhliso lweziseko. Zifanelekile zombini ukusetyenziswa ngaphezulu komhlaba kunye nangaphantsi komhlaba.

Ukumelana nokugqwala:Ukuphucula ubomi obude, imibhobho yentsimbi ejikelezayo idla ngokusetyenziswa unyango lokulwa nokugqwala. Oku kungabandakanya ukugqunywa kwangaphakathi nangaphandle, okufana ne-epoxy, i-polyethylene, kunye ne-zinc, ezikhusela imibhobho kwizinto ezingqongileyo kunye nezinto ezirhabaxa.

Iingenelo:Iipayipi zentsimbi ezijikelezayo zibonelela ngeenzuzo ezahlukeneyo, kuquka umthamo ophezulu wokuthwala umthwalo, ukusebenza kakuhle kweendleko kwiipayipi ezinkulu, ukulula kokufakelwa, kunye nokumelana nokuguquka. Uyilo lwazo olujikelezayo lukwanceda ekutsaleni amanzi ngendlela efanelekileyo.

I-LongitudinalVSI-Spiral:Iipayipi zentsimbi ezijikelezayo zahlukile kwiipayipi ezidibeneyo ezinde ngokwenkqubo yazo yokwenziwa. Ngelixa iipayipi ezinde zenziwe kwaye zidibeneyo kubude bombhobho, iipayipi ezijikelezayo zine-helical seam eyenziwe ngexesha lokwenziwa.

Ulawulo lwemeko:Iinkqubo zokuvelisa nokulawula umgangatho zibalulekile ekuveliseni imibhobho yentsimbi ejikelezayo ethembekileyo. Iiparameter zokuwelda, ijiyometri yemibhobho, kunye neendlela zokuvavanya zijongwa ngononophelo ukuqinisekisa ukuthotyelwa kwemigangatho kunye neenkcukacha zoshishino.

Imigangatho kunye neenkcukacha:Iipayipi zentsimbi ezijikelezayo zenziwa ngokuhambelana nemigangatho yamazwe ngamazwe neyeshishini efana ne-API 5L, ASTM, EN, kunye neminye. Le migangatho ichaza iipropati zezinto, iindlela zokuvelisa, kunye neemfuno zovavanyo.

Ngamafutshane, iipayipi zentsimbi ezijikelezayo zisisombululo esiguquguqukayo nesihlala ixesha elide kumashishini ahlukeneyo. Inkqubo yazo yokuvelisa eyahlukileyo, amandla angaphakathi, kunye nokufumaneka kwazo ngobukhulu obahlukeneyo kunegalelo ekusetyenzisweni kwazo ngokubanzi kwiziseko zophuhliso, uthutho, amandla, ulwakhiwo lwezibuko nokunye. Ukukhetha ngokufanelekileyo, ulawulo lomgangatho, kunye namanyathelo okukhusela umhlwa kudlala indima ebalulekileyo ekuqinisekiseni ukusebenza kwexesha elide kweepayipi zentsimbi ezijikelezayo.

Iinkcukacha

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250, Ibanga C350, Ibanga C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| I-ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Ububanzi(mm) | Ubukhulu bodonga (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Ukunyamezela Ububanzi Bangaphandle kunye Nobukhulu Bodonga

| Umgangatho | Ukunyamezelana koMzimba wePipe | Ukunyamezelana kwePipe End | Ukunyamezela Ubukhulu Bodonga | |||

| Ububanzi obungaphandle | Ukunyamezelana | Ububanzi obungaphandle | Ukunyamezelana | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ±0.75%D~±3mm | 60 | ±0.5%D~±1.6mm | 4mm | ±12.5%T~±15.0%T |

| 610 | ±0.5%D~±4mm | 610 | ±0.5%D~±1.6mm | Ubunzima ≥25mm | -3.00mm~+3.75mm | |

| OD>1430mm | - | OD>1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD<508mm | ≤±0.75% | OD<508mm | ≤±0.75% | OD<508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| I-API 5L PSL1/PSL2 | OD<60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | Ubungakanani≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| I-API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| I-ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| I-ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Intshi | OD mm | I-SCH40S mm | I-SCH5S mm | I-SCH10S mm | I-SCH10 mm | I-SCH20 mm | I-SCH40 mm | I-SCH60 mm | XS/80S mm | I-SCH80 mm | I-SCH100 mm | I-SCH120 mm | I-SCH140 mm | I-SCH160 mm | I-SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| I-DN 1000mm nangaphezulu Ububanzi bodonga lombhobho Ubude obuphezulu yi-25mm | ||||||||||||||||

Imigangatho kunye neBanga

| Umgangatho | Amanqanaba eNsimbi |

| I-API 5L: Inkcazo yePipe yoMgca | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: Inkcazo esemgangathweni yeePile zeMbhobho zeNsimbi eziWelded nezingenamthungo | GR.1, GR.2, GR.3 |

| I-EN 10219-1: Amacandelo angaphakathi adibeneyo afakwe kwisakhiwo esibandayo seentsimbi ezingezizo i-alloy kunye neentsimbi ezincinci | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: Amacandelo ashushu agqityiweyo olwakhiwo olungenanto yokuxuba kunye neentsimbi zengqolowa ezintle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: Ipayipi, Intsimbi, Imnyama kwaye Itshisiwe, Igqunywe ngeZinc, Idityanisiwe kwaye Ayinamthungo | GR.A, GR.B |

| EN 10217: Iityhubhu zentsimbi ezidityanisiweyo ngeenjongo zoxinzelelo | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-DIN 2458: Iipayipi zentsimbi edibeneyo kunye neetyhubhu | I-St37.0, I-St44.0, I-St52.0 |

| I-AS/NZS 1163: Umgangatho wase-Australia/waseNew Zealand weeCandelo zeNsimbi eziMgobo ezenziwe ngeNsimbi | Ibanga C250 , Ibanga C350 , Ibanga C450 |

| GB/T 9711: Amashishini ePetroleum neGesi yendalo - Umbhobho weNtsimbi weeMibhobho | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| AWWA C200: Umbhobho Wamanzi Wentsimbi 6 Iintshi (150 mm) kwaye Mkhulu | Intsimbi yeCarbon |

Inkqubo yoMveliso

Ulawulo lwemeko

● Ukujonga Izinto Ezingasetyenzwanga

● Uhlalutyo lweeKhemikhali

● Uvavanyo lweMishini

● Ukuhlolwa koMbono

● Ukujonga Ubungakanani

● Uvavanyo lokugoba

● Uvavanyo lweMpembelelo

● Uvavanyo lokuGqobhoka phakathi kweegranular

● Uvavanyo Olungonakalisiyo (UT, MT, PT)

● Isiqinisekiso seNkqubo yokuWelda

● Uhlalutyo lweMicrstructure

● Uvavanyo lokuGqiba nokuQoqa

● Uvavanyo loBulukhuni

● Uvavanyo loxinzelelo

● Uvavanyo lweMetallography

● Uvavanyo lokuGqobhoka

● Uvavanyo lwangoku luka-Eddy

● Ukuhlolwa kokupeyinta kunye nokugquma

● Uhlolo lwamaxwebhu

Ukusetyenziswa kunye neSicelo

Iipayipi zentsimbi ezijikelezayo zisetyenziswa ngeendlela ezahlukeneyo kwaye zisetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yeempawu zazo ezikhethekileyo kunye neenzuzo. Zenziwa ngokuhlanganisa imicu yentsimbi kunye nge-helical ukuze kwenziwe umbhobho onomthungo ojikelezayo oqhubekayo. Nazi ezinye zeendlela eziqhelekileyo zokusetyenziswa kweepayipi zentsimbi ezijikelezayo:

● Uthutho Oluhamba Ngolwelo: Le mibhobho ihambisa amanzi, ioyile kunye negesi ngokufanelekileyo kumgama omde kwimibhobho ngenxa yokwakheka kwayo okungenamthungo kunye namandla aphezulu.

● Ioyile negesi: Zibalulekile kumashishini eoyile negesi, zithutha ioyile ekrwada, igesi yendalo, kunye neemveliso ezicociweyo, zibonelela ngeemfuno zophando nokusasazwa.

● Ukuqokelela: Iimfumba zesiseko kwiiprojekthi zokwakha zixhasa imithwalo enzima kwizakhiwo ezifana nezakhiwo kunye neebhulorho.

● Ukusetyenziswa kwesakhiwo: Zisetyenziswa kwizakhelo zokwakha, iintsika, kunye nezixhaso, ukuqina kwazo kuncedisa ekuzinzeni kwesakhiwo.

● Ii-Culverts kunye ne-Drainage: Ezisetyenziswa kwiinkqubo zamanzi, ukumelana nokugqwala kwazo kunye nengaphakathi elithambileyo zithintela ukuvaleka kwaye ziphucula ukuhamba kwamanzi.

● Ukufakelwa kweeMibhobho zeMechanical: Kwimveliso nakwizolimo, ezi payipi zibonelela ngezisombululo ezingabizi kakhulu neziqinileyo zezixhobo.

● Ulwandle nolwandle: Kwiimeko ezinzima, zisetyenziswa kwimibhobho engaphantsi kwamanzi, kumaqonga olwandle, nakwizakhiwo zeenqanawa.

● Ukwemba: Zithwala izinto kunye nodaka kwimisebenzi yokwemba enzima ngenxa yokwakhiwa kwazo okuqinileyo.

● Ubonelelo lwaManzi: Lulungele imibhobho emikhulu kwiinkqubo zamanzi, luthutha ngokufanelekileyo umthamo wamanzi obalulekileyo.

● Iinkqubo zeGeothermal: Zisetyenziswa kwiiprojekthi zamandla e-geothermal, zisingatha ukudluliselwa kolwelo olumelana nobushushu phakathi kwamachibi kunye nezityalo zamandla.

Indlela eziguquguqukayo ngayo iipayipi zentsimbi ezijikelezayo, xa zidibene namandla azo, ukuqina kwazo, kunye nokuguquguquka kwazo, zizenza zibe yinxalenye ebalulekileyo kumashishini amaninzi kunye nezicelo zazo.

Ukupakisha kunye nokuthumela

Ukupakisha:

Inkqubo yokupakisha imibhobho yentsimbi ejikelezayo ibandakanya amanyathelo aliqela abalulekileyo ukuqinisekisa ukuba imibhobho ikhuselekile ngokwaneleyo ngexesha lokuthuthwa nokugcinwa kwayo:

● Ukubopha iipayipi: Iipayipi zentsimbi ezijikelezayo zihlala zibophana kusetyenziswa iintambo, iintambo zentsimbi, okanye ezinye iindlela zokubopha ezikhuselekileyo. Ukubopha kuthintela iipayipi nganye ukuba zingashukumi okanye zitshintshe ngaphakathi kwiphakheji.

● Ukhuseleko Lwesiphelo Semibhobho: Izigqubuthelo zeplastiki okanye izigqubuthelo zokukhusela zibekwe kuzo zombini iziphelo zemibhobho ukuthintela umonakalo kwiziphelo zemibhobho kunye nomphezulu wangaphakathi.

● Ukuthintela ukungenwa kwamanzi: Imibhobho isongwa ngezinto ezingangeni manzi, ezifana neeplastiki okanye ukusonga, ukuze ikhuseleke kumswakama ngexesha lokuthuthwa, ingakumbi xa kuthuthwa ngaphandle okanye elwandle.

● Ukugquma: Izinto ezongezelelweyo zokugquma, ezifana nezinto zokufaka igwebu okanye izinto zokugquma, zingongezwa phakathi kwemibhobho okanye kwiindawo ezibuthathaka ukuze zikwazi ukufunxa ukungcangcazela kunye nokungcangcazela.

● Ukubhala iilebheli: Iphakheji nganye ibhalwe ulwazi olubalulekileyo, kuquka iinkcukacha zombhobho, ubukhulu, ubungakanani, kunye nendawo ekuyiwa kuyo. Oku kunceda ekuchongeni nasekuphatheni lula.

Ukuhambisa ngenqanawe:

● Ukuthunyelwa kwemibhobho yentsimbi ejikelezayo kufuna ucwangciso olucokisekileyo ukuqinisekisa ukuthuthwa okukhuselekileyo nokufanelekileyo:

● Indlela Yothutho: Ukukhetha indlela yothutho (endleleni, kuloliwe, elwandle, okanye emoyeni) kuxhomekeke kwizinto ezifana nomgama, ukungxamiseka, kunye nokufikeleleka kwindawo oya kuyo.

● Ukufakwa kwiikhonteyina: Iipayipi zinokufakwa kwiikhonteyina eziqhelekileyo zokuthumela okanye kwiikhonteyina ezikhethekileyo ezibekwe ecaleni. Ukufakwa kwiikhonteyina kukhusela iipayipi kwizinto zangaphandle kwaye kubonelela ngendawo elawulwayo.

● Ukukhusela: Iipayipi ziqiniswa ngaphakathi kwezikhongozeli kusetyenziswa iindlela ezifanelekileyo zokubopha, ezinje ngokuziqinisa, ukuzivala, kunye nokuzibopha. Oku kuthintela ukuhamba kwaye kunciphisa umngcipheko wokonakala ngexesha lokuhamba.

● Amaxwebhu: Amaxwebhu achanekileyo, kuquka ii-invoyisi, uluhlu lokupakisha, kunye ne-manifest yokuthunyelwa, alungiselelwe iinjongo zokucoca irhafu kunye nokulandelela.

● I-inshorensi: I-inshorensi yempahla idla ngokufunyanwa ukuze ihlawule ilahleko okanye umonakalo onokubakho ngexesha lokuhamba.

● Ukubeka esweni: Kuyo yonke inkqubo yokuthumela, iipayipi zinokulandelwa kusetyenziswa i-GPS kunye neenkqubo zokulandelela ukuqinisekisa ukuba zikwindlela efanelekileyo kunye neshedyuli.

● Ukucocwa kweMithetho: Kunikezelwa amaxwebhu afanelekileyo ukuze kube lula ukucocwa kweMithetho kwizibuko okanye kumda oya kuwo.

Isiphelo:

Ukupakishwa kakuhle kunye nokuthunyelwa kwemibhobho yentsimbi ejikelezayo kubalulekile ukugcina umgangatho kunye nokuthembeka kwemibhobho ngexesha lokuthuthwa. Ukulandela iindlela ezilungileyo zoshishino kuqinisekisa ukuba imibhobho ifika kwindawo yayo ikwimeko efanelekileyo, ilungele ukufakwa okanye ukucutshungulwa ngakumbi.