Ingcaciso yeMveliso

Ulwazi oluQhelekileyo - ASME/ANSI B16.5 kunye ne-B16.47 - Iiflanges zePipe kunye neFlanged Fittings

Umgangatho we-ASME B16.5 ugubungela iinkalo ezahlukeneyo zeeflanges zepayipi kunye nezixhobo ezifakwe iflange, kubandakanya ukulinganiswa kobushushu boxinzelelo, izixhobo, ubungakanani, ukunyamezela, ukumakisha, ukuvavanya, kunye nokukhetha iindawo ezivulekileyo zezi zinto. Lo mgangatho ubandakanya iiflanges ezineempawu zeklasi yokulinganisa ukusuka kwi-150 ukuya kwi-2500, ezigubungela ubungakanani ukusuka kwi-NPS 1/2 ukuya kwi-NPS 24. Ubonelela ngeemfuno kuzo zombini iiyunithi ze-metric kunye neze-US. Kubalulekile ukuqaphela ukuba lo mgangatho ulinganiselwe kwiiflanges kunye nezixhobo ezifakwe iflanges ezenziwe ngezinto ezixonxiweyo okanye ezixonxiweyo, kubandakanya iiflanges ezingaboniyo kunye neeflanges ezithile zokunciphisa ezenziwe ngezinto ezixonxiweyo, ezixonxiweyo, okanye zepleyiti.

Kwi-flanges zepayipi kunye ne-flanged fittings ezinkulu kune-24" NPS, kufuneka kubhekwe i-ASME/ANSI B16.47.

Iintlobo zeFlange eziqhelekileyo

● Iiflanges ezityibilikayo: Ezi flanges zihlala zigcinwe kwi-ANSI Class 150, 300, 600, 1500 kunye ne-2500 ukuya kuthi ga kwi-24" NPS. "Zityibilikiswa phezu" kombhobho okanye iziphelo zokudibanisa kwaye zitshixiwe kwindawo yazo, zivumela ii-fillet welds ngaphakathi nangaphandle kweflange. Iinguqulelo zokunciphisa zisetyenziselwa ukunciphisa ubungakanani bemigca xa indawo incinci.

● Iiflanges zeNtlalo eziWeld: Ezi flanges zinehabhu ende ethe tyaba eyahlukileyo kunye notshintsho olugudileyo lobukhulu, okuqinisekisa unxibelelwano olupheleleyo lwe-weld kumbhobho okanye kwi-fitting. Zisetyenziswa kwiimeko ezinzima zenkonzo.

● Iiflanges zeLap Joint: Zidityaniswe nesiphelo sestub, iiflanges zelap joint zityibilika phezu kwe-stub end fitting kwaye ziqhagamshelwe nge-welding okanye ezinye iindlela. Uyilo lwazo olukhululekileyo luvumela ukulungelelaniswa okulula ngexesha lokuhlanganiswa nokuqhekeka.

● Iiflanges Ezixhasayo: Ezi flanges azinabuso buphakamileyo kwaye zisetyenziswa neeringi ezixhasayo, zibonelela ngezisombululo ezingabizi kakhulu zokuqhagamshela iiflanges.

● Iiflanges ezinemisonto (ezineeskrufu): Zidiniwe ukuze zilingane nombhobho othile ngaphakathi kobubanzi, iiflanges ezinemisonto zifakelwa imisonto yepayipi enciphileyo kwicala elingasemva, ikakhulu kwiipayipi ezincinci.

● Iiflanges zeSocket Weld: Ezifana neeflanges ezityibilikayo, iiflanges zesocket weld zenziwa ngomatshini ukuze zihambelane neesokethi ezinobukhulu bombhobho, nto leyo evumela ukuwelda kwefillet kwicala elingasemva ukuqinisekisa uqhagamshelo. Zihlala zisetyenziselwa iipayipi ezincinci.

● Iiflanges ezingaboniyo: Ezi flanges azinamngxuma usembindini kwaye zisetyenziselwa ukuvala okanye ukuvala isiphelo senkqubo yepayipi.

Ezi zezinye zeentlobo eziqhelekileyo zeeflanges zepayipi ezisetyenziswa kwizicelo ezahlukeneyo zoshishino nezorhwebo. Ukukhethwa kohlobo lweflange kuxhomekeke kwizinto ezifana noxinzelelo, ubushushu, kunye nohlobo lolwelo oluthuthwayo, kunye neemfuno ezithile zeprojekthi. Ukukhethwa kunye nokufakelwa kweeflanges ngokufanelekileyo kubalulekile ekusebenzeni ngokukhuselekileyo nangokufanelekileyo kweenkqubo zepayipi.

Iinkcukacha

| I-ASME B16.5: Intsimbi yekhabhoni, intsimbi engatyiwayo, intsimbi ye-alloy |

| EN 1092-1: Intsimbi yekhabhoni, intsimbi engatyiwayo, intsimbi ye-alloy |

| I-DIN 2501: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi ye-Alloy |

| I-GOST 33259: Intsimbi yeCarbon, Intsimbi Engagqwaliyo, Intsimbi ye-Alloy |

| I-SABS 1123: Intsimbi yeCarbon, iNtsimbi engatyiwayo, iNtsimbi yeAlloy |

Izixhobo zeFlange

Iiflanges zidityaniswa kwipayipi nakwi-nozzle yezixhobo. Ngoko ke, zenziwe ngezinto ezilandelayo;

● Intsimbi yekhabhoni

● Intsimbi ephantsi ye-alloy

● Intsimbi engenasici

● Ukudibanisa izinto zangaphandle (iStub) kunye nezinye izinto ezixhasayo

Uluhlu lwezinto ezisetyenziswa ekuvelisweni lugutyungelwe kwi-ASME B16.5 kunye ne-B16.47.

● I-ASME B16.5 -Iiflanges zePipe kunye neFlanged Fittings NPS ½” ukuya kwi-24”

● I-ASME B16.47 -Iiflanges zentsimbi ezinkulu ezinobubanzi obuyi-NPS 26” ukuya kwi-60”

Izinto ezisetyenziswa rhoqo

● Intsimbi yeKhabhoni: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Intsimbi ye-Alloy: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Intsimbi Engagqwaliyo: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Ubukhulu beFlange yeClass 150 Slip-on

| Ubungakanani nge-intshi | Ubungakanani nge-mm | I-Dia yangaphandle. | I-Flange Eqinileyo. | I-Hub OD | Ubude beFlange | I-RF Dia. | Ukuphakama kweRF | I-PCD | Ibhorethi yeSocket | Inani leeBolts | Ubungakanani beBolt UNC | Ubude beBolt yoMatshini | Ubude be-RF Stud | Ubungakanani beHole | Ubungakanani be-ISO Stud | Ubunzima nge kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | I-M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | I-M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | I-M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | I-M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | I-M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Ubukhulu beFlange yeNtlalo yeWeld yeKlasi 150

| Ubungakanani nge-intshi | Ubungakanani nge-mm | Ububanzi obungaphandle | Ubukhulu beFlange | I-Hub OD | Intamo yeWeld OD | Ubude bentamo yokuWelda | Ibhore | Ububanzi beRF | Ukuphakama kweRF | I-PCD | Ubuso obuWeldiweyo |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Ukuwelda Imbobo yentamo ithathwe kwishedyuli yepayipi | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Ubukhulu beFlange yeBlind yeKlasi ye-150

| Ubungakanani | Ubungakanani | Ngaphandle | Iflengi | RF | RF | I-PCD | Inani le | Ubungakanani beBolt | Ibholthi yomatshini | I-RF Stud | Ubungakanani beHole | Isifundo se-ISO | Ubunzima |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | I-M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | I-M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | I-M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | I-M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | I-M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Imigangatho kunye neBanga

| I-ASME B16.5: Iiflanges zePipe kunye neFlanged Fittings | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| I-EN 1092-1: Iiflanges kunye namajoyinti azo - Iiflanges ezijikelezayo zeepayipi, iivalvu, izixhobo, kunye nezixhobo, i-PN echongiweyo - Icandelo 1: Iiflanges zentsimbi | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy

|

| I-DIN 2501: Iiflanges kunye namaLungelo adibeneyo | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| I-GOST 33259: Iiflanges zeeValve, izixhobo, kunye neePipelines zoxinzelelo kwi-PN 250 | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

| I-SABS 1123: Iiflanges zeMibhobho, iiValve, kunye neZilinganisi | Izixhobo: Intsimbi yeCarbon, Intsimbi engatyiwayo, Intsimbi yeAlloy |

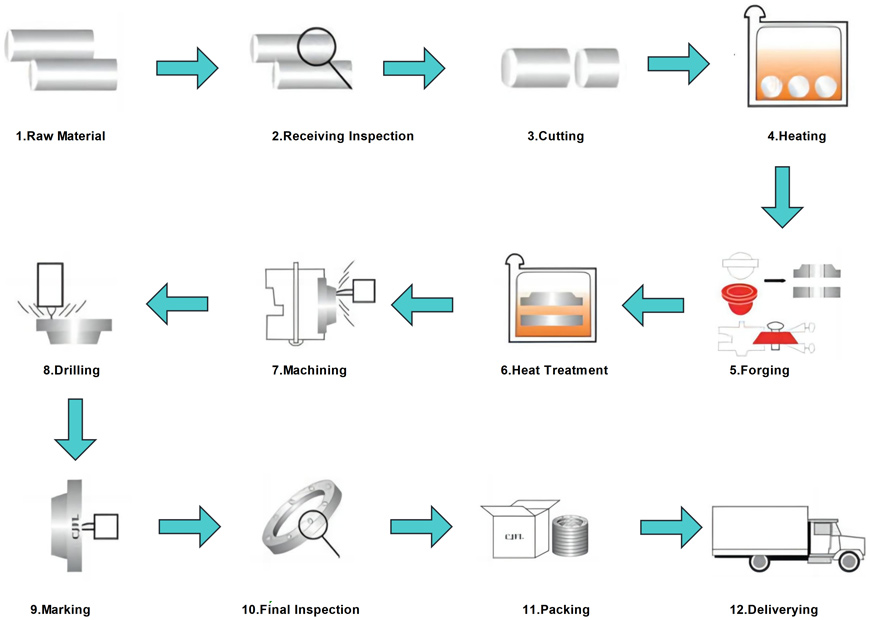

Inkqubo yoMveliso

Ulawulo lwemeko

Ukujonga Izinto Eziluhlaza, Uhlalutyo lweeKhemikhali, Uvavanyo lweeMechanical, Uhlolo olubonakalayo, Ukujonga ubungakanani, Uvavanyo lokugoba, Uvavanyo lokuthamba, Uvavanyo lweMpembelelo, Uvavanyo lwe-DWT, Uvavanyo olungonakalisiyo (UT, MT, PT, X-Ray,), Uvavanyo loBulukhuni, Uvavanyo loxinzelelo, Uvavanyo lokuvuza kwesihlalo, Uvavanyo lweMetallography, Uvavanyo lokugqwala, Uvavanyo lokumelana nomlilo, Uvavanyo lokutshiza ngetyuwa, Uvavanyo lokusebenza kokuhamba kwamanzi, Uvavanyo lweTorque kunye neThrust, Uvavanyo lokupeyinta kunye nokufaka ipeyinti, Uhlolo lwamaxwebhu…..

Ukusetyenziswa kunye neSicelo

Iiflanges zizinto ezibalulekileyo zoshishino ezisetyenziselwa ukudibanisa imibhobho, iivalvu, izixhobo kunye nezinye izinto zombhobho. Zidlala indima ebalulekileyo ekudibaniseni, ekuxhaseni nasekuvaleni iinkqubo zombhobho. Iiflanges zisebenza njengezinto ezibalulekileyo kwizicelo ezahlukeneyo zoshishino, kuquka:

● Iinkqubo zoMbhobho

● Iivalvu

● Izixhobo

● Unxibelelwano

● Ukutywina

● Ulawulo loxinzelelo

Ukupakisha kunye nokuthumela

Apha eWomic Steel, siyaqonda ukubaluleka kokupakishwa okukhuselekileyo kunye nokuthunyelwa okuthembekileyo xa kufikwa ekuziseni izixhobo zethu zombhobho ezikumgangatho ophezulu emnyango wakho. Nantsi ingcaciso emfutshane yeenkqubo zethu zokupakisha kunye nokuthunyelwa ukuze ufumane ireferensi yakho:

Ukupakisha:

Iiflange zethu zepayipi zipakishwe ngononophelo ukuqinisekisa ukuba zifikelela kuwe zikwimeko entle, zilungele iimfuno zakho zoshishino okanye zorhwebo. Inkqubo yethu yokupakisha ibandakanya la manyathelo aphambili alandelayo:

● Ukuhlolwa koMgangatho: Ngaphambi kokuba zipakishwe, zonke iiflanges zihlolwa ngononophelo lomgangatho ukuqinisekisa ukuba ziyahlangabezana nemigangatho yethu engqongqo yokusebenza nokuthembeka.

● Ukwaleka Okukhuselekileyo: Ngokuxhomekeke kuhlobo lwezinto ezisetyenziswayo kunye nokusetyenziswa kwazo, iiflange zethu zinokufumana ukwaleka okukhuselekileyo ukuthintela ukugqwala kunye nomonakalo ngexesha lokuthuthwa.

● Ukubopha Okukhuselekileyo: Iiflange zihlanganiswa ndawonye ngokukhuselekileyo, ukuqinisekisa ukuba zihlala zizinzile kwaye zikhuselekile kuyo yonke inkqubo yokuthumela.

● Ukubhala iilebheli kunye noXwebhu: Iphakheji nganye ibhalwe ngokucacileyo ngolwazi olubalulekileyo, kubandakanya iinkcukacha zemveliso, ubungakanani, kunye nayo nayiphi na imiyalelo ekhethekileyo yokuphatha. Amaxwebhu afanelekileyo, anjengeziqinisekiso zokuthobela umthetho, nawo afakiwe.

● Ukupakisha Ngokwezifiso: Singakwamkela izicelo zokupakisha ezikhethekileyo ngokusekelwe kwiimfuno zakho ezikhethekileyo, siqinisekisa ukuba iiflange zakho zilungiselelwe kanye njengoko kufuneka.

Ukuhambisa ngenqanawe:

Sisebenzisana namaqabane ethu okuthumela impahla athembekileyo ukuqinisekisa ukuhanjiswa okuthembekileyo nokufike ngexesha elifanelekileyo kwindawo ochaziweyo. Iqela lethu lezothutho liphucula iindlela zokuthumela impahla ukuze linciphise amaxesha okuthutha impahla kwaye linciphise umngcipheko wokulibaziseka. Kwiimpahla zamanye amazwe, sijongana nazo zonke iimpepha zempahla ezifunekayo kunye nokuthobela imithetho ukuze kube lula ukususwa kwempahla ngendlela ethe tye. Sinikezela ngeendlela zokuthumela impahla eziguquguqukayo, kubandakanya ukuthunyelwa ngokukhawuleza kwiimfuno ezingxamisekileyo.